| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Laminated Packaging Film |

|---|---|

| Brand Name: | Upass |

| Model Number: | Cross Laminated Film |

| Certification: | CE, ROHS |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 200,000㎡~300,000㎡ |

| Delivery Time: | 15days |

| Packaging Details: | Bubble Wrap & Wooden Pallet |

| Product Name: | Explosive Cartridges Application Laminated Packaging Film |

| Material: | HDPE |

| Production Process: | Cross Laminated |

| Performance: | Thermal Dimensional Stability |

| Thickness: | 0.09-0.26 |

| Width: | 100-1250mm |

| Color: | Black, Grey, Blue, Green, etc. |

| Application: | Label Material, Packing Film |

| Printing: | Can be customizable |

| Sample: | Available |

| Company Info. |

| Upass Material Technology (Shanghai) Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Explosive Cartridges Application Laminated Packaging Film

Description:

It is a high-strength multi-layer composite film,It is made of HDPE as the base material,

adding plasticizer, plasticizer, stabilizer, antioxidant, UV absorber, toughener and other

additives through multi-layer co-extrusion blow molding into embryos, and then by multiple

pull Stretching, then rotary cutting into a film substrate with a horizontal and vertical

distribution of 45 °, and finally through cross-compositing. Due to its cross-stacking

structure is different from ordinary single-layer or multi-layer film, it has the thermal stability,

dimensional stability, two-way tear resistance, two-way uniform tension and high elongation

which are not available in traditional films.

Phameter:

| NO. | Item | Performance | ||

| SDM-30 | SDM-60 | |||

| 1 | Tensile Property | Tensile Strength/Mpa ≥ | 30 | 50 |

| MaxF/(N/50mm) ≥ | 200 | 300 | ||

| Elongation as MaxF/% ≥ | 200 | |||

| Elongation at break/% ≥ | 250 | |||

| 2 | Sample number of no broken tested by free-falling dart method ≥ | 8 | ||

| 3 | Tear Strength(Nail Shank)/N ≥ | 60 | ||

| 4 | Angle Tear Strength/N ≥ | 25 | ||

| 5 | Thermal Stability | 120 ℃,10min, No bulb, No deformation | ||

| 6 | Cryogenic Flexibility ℃ | -35℃, No fissure, No delamination | ||

| 7 | Thermal Ageing | Appearance | No bulb, No deformation | |

| Subsequent MaxF/% ≥ | 80 | |||

| Elongation at MaxF/% ≥ | 200 | |||

| Elongation at break/% ≥ | 200 | |||

| 8 | Artificial Weathering | Appearance | No bulb, No deformation | |

| Subsequent MaxF/% ≥ | 70 | |||

| Elongation at MaxF/% ≥ | 180 | |||

| Elongation at break/% ≥ | 180 | |||

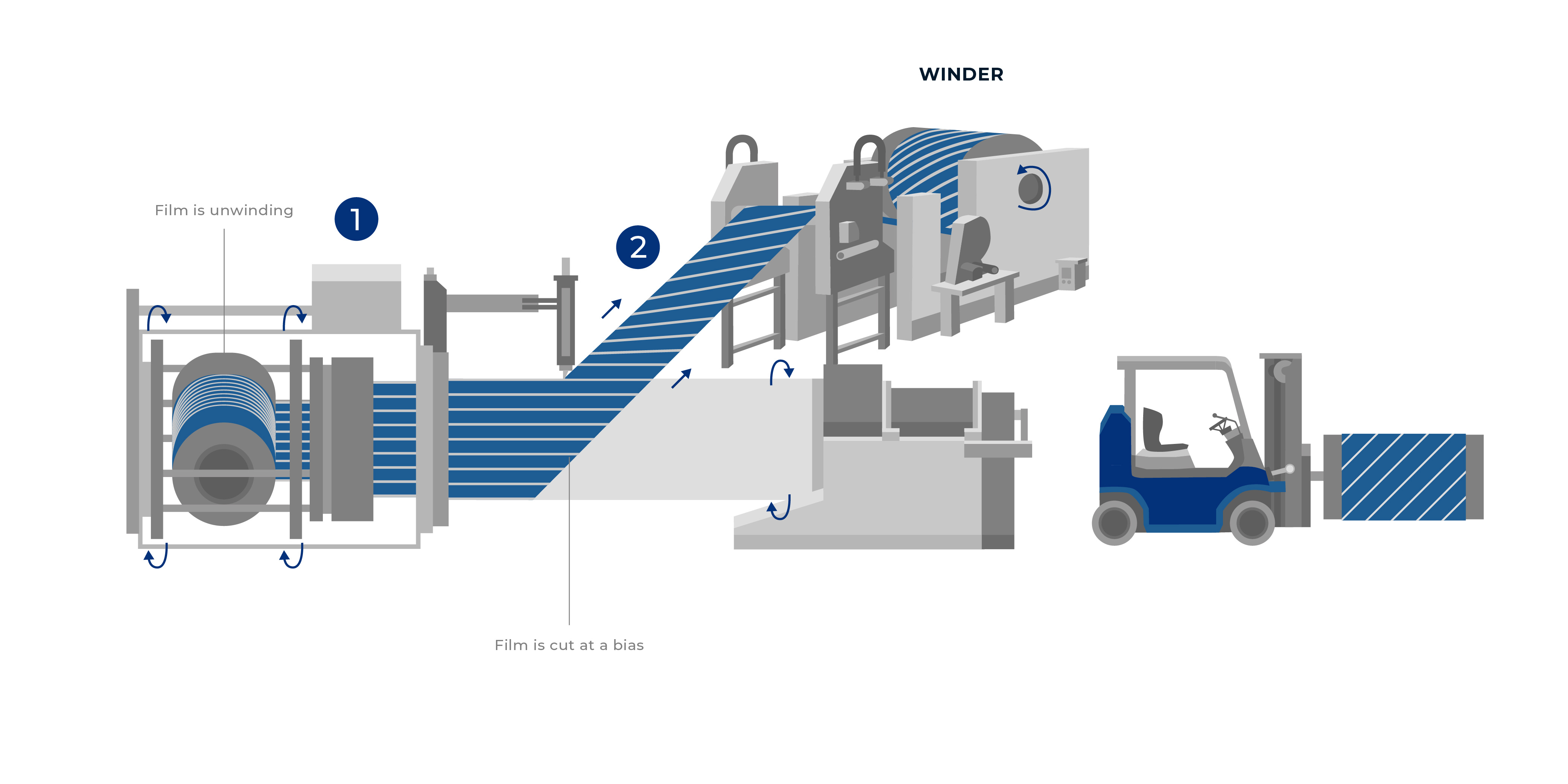

Production Process:

OUR THREE STEP PROCESS FOR MANUFACTURING HIGH STRENGTH, DURABILITY,

AND QUALITY CROSS LAMINATED FILM.

Advantages:

|

Application:

|