| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Juice Filling Machine |

|---|---|

| Brand Name: | BIEVO |

| Model Number: | RGF18-18-6 |

| Certification: | CE, ISO 9001:2008 |

| Place of Origin: | China,Jiangsu |

| MOQ: | 1set |

| Price: | 15000dollers/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 30 working days |

| Packaging Details: | wood case |

| Type: | Filling machine |

| Automatic Grade: | automatic |

| Material: | SUS 304/316 |

| Voltage: | 220V / 380V / 415V |

| Dimension(L*W*H): | by model |

| Weight: | 2500KG |

| Machine Material: | 304 stainless steel |

| Filling precision: | ≤±5mm |

| Packaging Material: | wood |

| filling temperature: | 85C |

| Condition: | new |

| Key Selling Points: | Full automatic |

| Wash: | pure water wash |

| blending system: | steam heating |

| packaging: | film shrink wrapping machine or carton packing machine |

| Workshop Layout: | Free Design |

| Power: | 3.5kw |

| Driven Type: | Electric |

| Machinery Capacity: | 5000bph |

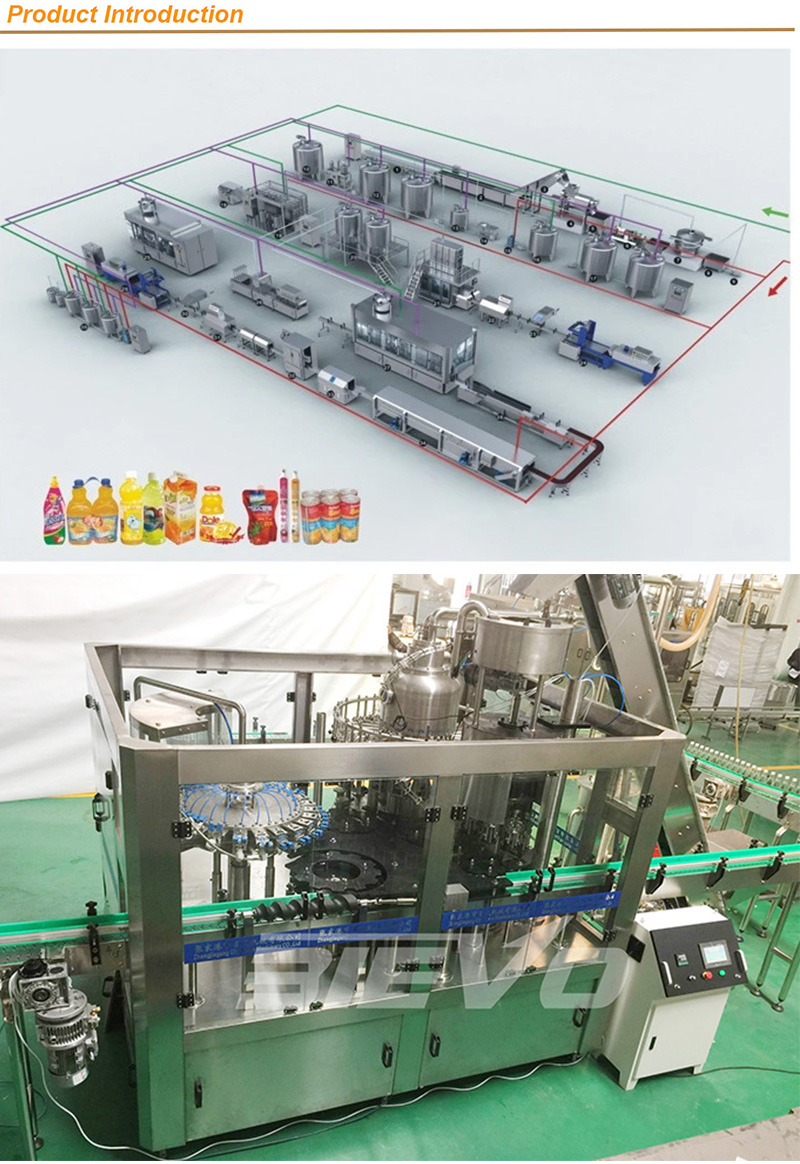

6000BPH Small Juice/Ejuice/Juicer/Juce Filling Machine Automatic Line

1. The filling line is mainly used in the beverage filling

operations. The three functions of bottle wash, fill and seal are

composed in one body of the machine. The whole process is

automatic.

2. The machine is used in filling juices,beverage in bottles made

of polyester and plastics. The machine can also be used in hot

filling if being installed with temperature controlling device. The

handle of the machine can be freely and conveniently turned to

adjust the machine to fill various types of bottles.

3. The filling operation is faster and more stable because the

micro pressure filling operation of the new type is adopted. There

the output and benefit of the machine is higher than the machinery

of the same specifications.

4. The advanced OMRON programmed controller (PLC) is adopted to

control the machine to run automatically while a transducer is used

in the bottle -entering chains to adjust speeds and coordinated

with the transducer of the main machine to make the operations of

moving bottle forward steadily and reliably.

5. It is convenient to operate with higher automation because every

part of the machine is inspected to run with photo electricity, On

the bases, the filling parts of the machine can be changed into

filling methods of lower vacuum.

Product Features -

This CGF Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

![]()

| Model | RGF14-12-4 | RGF18-18-6 | RGF24-24-8 | RGF32-32-10 | RGF40-40-12 | RGF50-50-15 |

| Capacity | 3000BPH | 6000BPH | 8000BPH | 10000BPH | 15000BPH | 22000BPH |

| Washing No | 14Heads | 18Heads | 24Heads | 32Heads | 40Heads | 50Heads |

| Filling No | 12Heads | 18Heads | 24Heads | 32Heads | 40Heads | 50Heads |

| Capping No | 4Heads | 6Heads | 8Heads | 10Heads | 12Heads | 15Heads |

| Diameter of bottles :50-100mm | ||||||

| Height of bottle :100-300mm | ||||||

| Motor power | 2.2KW | 3.7KW | 5.5KW | 7.5KW | 11KW | 15KW |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

Q1: Do you have reference project?

A1: We have reference project in most countries,If we get the

permission of the customer who has brought the machines from us

,you can go to vist their factory.

And you are always welcome to come to visit our company,and see the

machine running in our factory,we can pick you up from the station

near our city. Our sales people you can get video of our reference

running machineIn our nearby city has a Coca cola factory, they are

buy our machine, we can take you to visit.

Q2: Do you have agent and after-service stations?

A2: So far we have agent in Indonsia, Malaysia, Vietnam, South

Africa, Thailand etc.. welcome to join us!

Q3: Do you provide customized service

A3: We can design the machines according your requirements(materil

,power,filling type,the kinds of the bottles,and so on),at the same

time we will give you our professional suggestion,as you know,we

have been in this industry for many years.

Q4: What's your guarantee or the warranty of the quality if we buy

your machines?

A4: We offer you high quality machines with 1 year guarantee and

supply life-long technical support.

Q5: How long time for installation?

A5: According your machines order,we will send one or two engineers

to your plant,it will take about 10 days to 25 days.

<1>Installation, debug

After equipment reached the workshop of customer, place the

equipment according to plane layout we offered. We will arrange

seasoned technician for equipment installation, debug and test

production at the same time make the equipment reach the rated

producing capacity of the line. The buyer need to supply the round

tickets and accommodation of our engineer, and the salary.

<2>Training

Our company offer technology training to customer. The content of

training is structure and maintenance of equipment, control and

operation of equipment. Seasoned technician will guide and

establish training outline. After training, the technician of buyer

could master the operation and maintenance, could adjust the

process and treat different failures.

<3>Quality guarantee

We promise that our goods are all new and not used. They're made of

suitable material, adopt new design. The quality, specification and

function all meet the demand of contract. We promise that the

products of this line could storage for one year without adding any

aseptic.

|