| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Die Casting Mold |

|---|---|

| Brand Name: | GT |

| Model Number: | Aluminum Die Casting Mold |

| Certification: | ISO 9001 , IGS |

| Place of Origin: | Dongguan China |

| MOQ: | 1 mold |

| Price: | Negotiate |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Mold Type: | Aluminum Die Casting Mold |

| Runner: | Cold / Hot |

| Design software: | UG , PROE , CAD |

| Plastic Material: | PP, PC , PS , PE |

| Product Material: | aluminium, zinc, brass |

| Mould base: | Futaba , Lkm , Hasco , Dme |

| Cavity: | Single Mould |

| Tolerance: | Up to 0.01mm |

| Company Info. |

| TAKDA PRECISE MOULD FACTORY |

| View Contact Details |

| Product List |

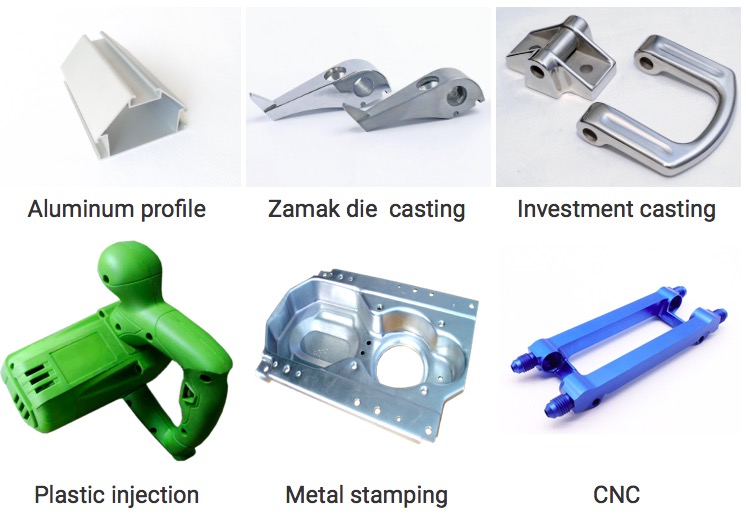

Our Capabilities

| Casting Solution | Die Casting; Low Pressure Die Casting; Investment Casting; Sand Casting |

| Subsequent Process | CNC Machining; Surface Treatment |

| Surface Treatment | Polishing, Sand blasting, Heat treatment, Painting, Powder coating, Anodizing, Electroplating, Chrome plating |

| Testing | Dimension and Appearance Inspection; Nondestructive Testing |

| Product | Automotive; Daily hardware; Electronics industry; Machine tool industry; Medical equipment; Machine Part and etc. |

Product Description

Global Manufacturer of Custom Engineered Aluminum Die Casting

Tooling;

Engineering With excellent dimensional accuracy;

Customer Oriented & Quality Adherence;

Competitively Priced Aluminum Die Casting Toolings;

Aluminum Molding Casting Tooling

Standard:DME,HASCO,LKM,CUMSA,MISUMI,DAIDO.

| Product | OEM aluminum die casting mold for Led housing & Heatsink Auto parts |

| Machine | Die casting machine 120 ton- 1200 ton |

| Process | Drawing & Samples → Mould making → Die casting → Deburring→Drilling and threading → CNC Machining → Polishing → Surface treatment → Assesmbly → Quality inspection → Packing → Shipping |

| SurfaceTreatment | Polishing, Sandblasting, Painting, Powder coating ,Galvanizing, Chrome plating |

| Application | Lighting Componets. Led heatsink .Led housing. Auto & moto Accessoies and parts. Furniture accessories. Mechanical parets Other Accessories. |

| Drawing file | IGS . STEP . SLD . X_T . DXF .DWG . SAT . STL. |

| ISO Certificate | ISO9001-2012 |

| Our advantage | More than 10 years of experiences in die casting field |

| Physical properties comparison of different die casting alloy | ||||

| Aluminum | Brass | Magnesium | Zinc | |

| Tensile strength,psi*1000 | 47 | 55 | 34 | 41 |

| Yield strength,psi*100(0.2 pct offset) | 23 | 30 | 23 | |

| Shear strength,psi*1000 | 28 | 37 | 20 | 31 |

| Fatigue strength,psi*1000 | 20 | 25 | 14 | 7 |

| Elongaton,pct in 2 in. | 3.5 | 15 | 3 | 10 |

| Hardness (Brinell) | 80 | 91 | 63 | 82 |

| Specific gravity | 2.71 | 8.3 | 1.8 | 6.6 |

| Weight,lb/cu.in. | 0.098 | 0.305 | 0.066 | 0.24 |

| Melting ponint (liquid),°F | 1100 | 1670 | 1105 | 728 |

|