| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ready Mix Concrete Batch Plant |

|---|---|

| Brand Name: | ENCKE |

| Model Number: | 100 -150m3 |

| Certification: | CE |

| Place of Origin: | Mainland |

| MOQ: | 1 set |

| Payment Terms: | T/T, L/C, D/P, Western Union, MoneyGram |

| Delivery Time: | 20-30 work days |

| Packaging Details: | Stand Container |

| Price: | negotiate |

| Item: | Dry Mortar Batch Plant Manufacture Dry Mixing Plant |

| Aggregate batcher: | 4m3/7m3/13m3/ customer designed |

| Discharging height: | 3.8m( customized designed) |

| Main equipment: | dry mixing plant batcher ,cement silo ,screw conveyor |

| Application: | quick cement mixing |

| Name: | dry mix mortar production line |

| Company Info. |

| Shandong Encke Imp&Exp Co.,LTD |

| View Contact Details |

| Product List |

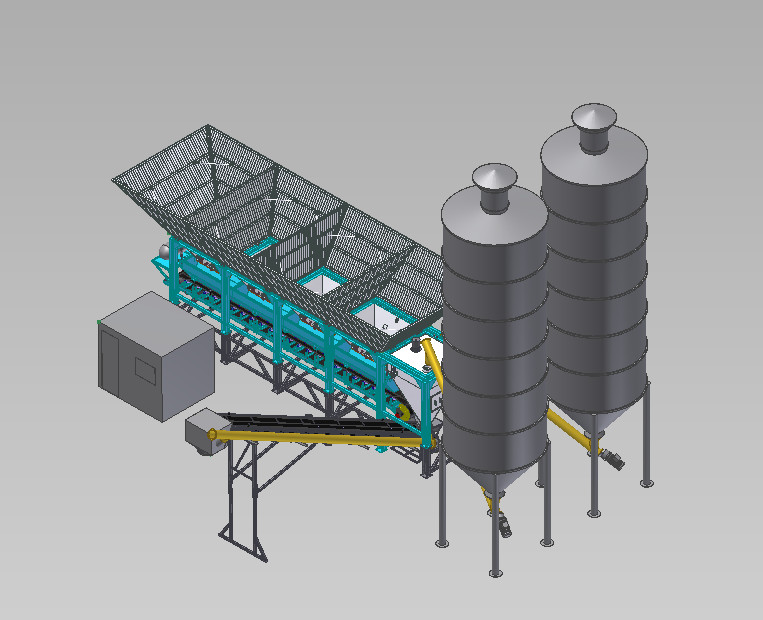

Dry Mortar Batch Plant Manufacture Dry Mixing Plant

A Dry mortar batch plant is also called dry mixing plant. Including aggregates and powders, are directly discharged into a concrete mixer truck for further mixing after being weighed. Correspondingly, the equipment for a dry mortar batch plant includes:cement silo , feeding system, control system, weighing system and mixing system. Cement silos is used to stock raw materials such as cement, sand, and fly ash according to the necessity of the production. Feeding system is to conveying aggregates .The accuracy of weighing system determines the quantity of the mixed materials, so it has a great effect on the quality of mixed concrete. The mixing system just mix the materials together without water. As a result, the mixer truck is important to convey and mix the concrete. The total dry mortar batch plant is controlled by PLC electric system .

The main difference between dry and wet batch plants is that the dry mortar batch plant without a concrete mixer, they use a concrete mixer truck to mix and transport concrete. So dry mortar batch plant called as "transit mix concrete plant"Dry mortar batch plants has a lower initial investment than wet batching plants.

.

Technical Features:

Item | EDY50 | EDY60 | EDY75 | EDY100 | GDY120 |

Aggregate Bins | 3*7m3 | 4*7m3 | 4*15m3 | 4*15m3 | 4*15m3 |

Cement weighing hopper | 750L | 750L | 700L*2 | 700L*2 | 1000L*2 |

Belt conveyor | 800mm*12m | 800mm*12m | 1000mm*12m | 1000mm*12m | 1000mm*12m |

Screw conveyor | 219*11m | 219*11m | 273*11m | 323*11m | 323*11m |

Cement silo | 2*100 tons | 2*100 tons | 2*200 tons | 2*300tons | 4*200 tons |

Dry Mortar Batch Plant Manufacture Dry Mixing Plant

Dry mortar batch plant

Minimal foundation works

Possibility of moving the plant from one site to another

Low maintenance costs

Pre-cabled and pre-assembled at the workshop

Speed of assembling in site

Easy and cheap transport

Dry concrete mixing plant can be customized !

Detail show:

|