| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cement Production Equipment |

|---|---|

| Brand Name: | Pengfei |

| Model Number: | Φ2.2,Φ2.4Φ3,Φ3.2,Φ3.5,Φ3.8 |

| Certification: | CE,ISO |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 set |

| Price: | USD250000-USD4000000 |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 1 SET+120days |

| Delivery Time: | 120 days |

| Packaging Details: | All the packing is suitable for the sea worthy packing and inland packing 1.the heavy machinery can be bolted on the cushion, the equipments and parts easy to be corrosion is packed in wooden box. the liners and etc is packed in the iron frame.2.the differ |

| Capacity: | 10tph-150tph |

| Shell Material: | Q235A |

| Working days: | Continously working |

| Color: | As per your requirement |

| Company Info. |

| JIANGSU PENGFEI GROUP CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Φ4*(8+3)m coal mill for grinding coal in coal plant and in different production line

Pengfei 150tph 8m Cement Production Equipment

Coal mill

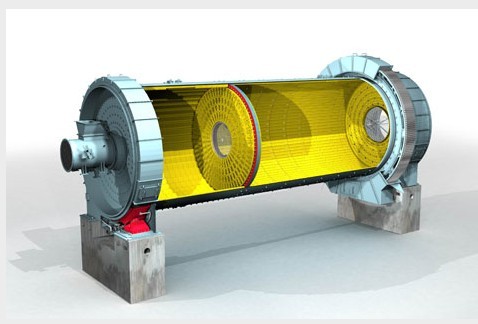

It is made up of the feede device,main bearing,rotary part,driving device,discharge device,high pressure starting device and lubricating system

The coal mill features rational structure and high grinding efficiency.it is an ideal equipment for pulverized coal preaparation.

The specification of ball mill

| Make/Type | - | |

| Design capacity | tph | 105 |

| Specific power consumption at shaft | kW/t | 33.5 |

| Product size (blaine) | cm2/g | 3600 |

| Residue on 90 m | % | 2 |

| Mill ventilation | Nm3/h | 43500 |

| Mill speed | rpm | 15.6 |

| Percentage of criticaL speed | % | 76.5 |

| Total weight - excluding electric motors | t | 340 + 280 ( Grinding Media) |

The Scope of ball mill

| 1,Rotary part | 1set |

| Shell | 1pcs |

| Inlet and outlet hollow shaft | 2pcs |

| Inlet and outlet spiral shell | 2pcs |

| Double diaphragm unit | 1set |

| Liners and bolts | 1set |

| 2,Main bearing (Include shaft bush) | 2sets |

| 3,Inlet unit | 1set |

| 4,Outlet unit(Include connection pipe) | 1set |

| 5,Drive unit | 1set |

| Main motor YRKK710-8 1250kW 3300V(Chongqing motor manufacture) | 1pcs |

| Main gear box MFY125A (Include thin oil station)(NGC) | 1pcs |

| Auxiliary drive unit MJM560 | 1set |

| Diaphragm coupling MFY120L | 1set |

| Base frame for drive unit | 1pcs |

| 6,Thin oil station GYXZ-40A | 2sets |

| 7,Foundation bolts | 1set |

| 8,Control cabinet (HP control,LP start,thin oil station control) | 1pcs |

Dry process ball mill

Model PMG ball mill has adopted special intergrate diaphragm and discharge grate to adjust material levels of every chamber so as to increase air ventilation and improve conditions inside mill,meanwhile it has also used new type of lining plate,regulated mill rotation speed,optimized design of pinion&girth gear and lubricating parameters of bearings sso as to increase its operational stability,use life and grinding efficiency.

After being put into practice,it is proved that its output has been increased about 20% and unit product power consumption has been reduced 10%-12% down under the conditions that other parameters have not been changed by comparision to other same sized ball mill,while being operated in open circuit,specific surface of cement could be reached up to 320cm/kg performance of it is up to national advaned standard,it has been awarded as well-known brand product of China building material industry,well know brand product of Jiagnsu Province,state star plan products,appointed manufacture of National building material machinery industry etc.

The structure of ball mill

Workshop Photos

|