| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cement Production Line |

|---|---|

| Brand Name: | Zhongke |

| Certification: | CE,ISO9001,ISO14001 |

| Place of Origin: | Henan, China (Mainland) |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1 set per month |

| Delivery Time: | 60 days |

| Packaging Details: | Nude, steel or wooden case |

| Name: | Automatic Cement Rotary Kiln For Calcination Production Line |

| Seed regulation Range(r/min): | 1000/1500 |

| Rated voltage(V): | 440/220 |

| No.of supporters: | 3 |

| After-sale service: | Life-long |

| Color: | As customer required |

| Capacity(t/d): | 300,600-700,1000,1200,1500-1800 |

| Installation: | Offer professional engineer for guidance |

| Type: | Cement Production Line |

Automatic Cement Rotary Kiln For Calcination Production Line

Cement is essential materials for construction buiding, it is made from stones which mainly is limestone, coal.

Description

Rotary Kiln refers to rotating calcination kiln, belongs to construction material equipment. According to different materials, rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln. The cement kiln is used for makeing cement clinker and there are dry and wet methods to make cement. Metallurgy chemical kiln is applied in metallurgy industries and ironworks for lean iron ore, chromium ore and ferronickel ore calcination. Lime kiln is mainly used for calcine dolomite and active lime which is used in steel plant and ferroalloy factory.

Features

Rotary kiln has simply structure, easy operation in producing, less wearing parts, high efficiency,it's used in the cement plant to calcine high grade cement, at the same time can be used in metallurgy,chemical,constructure ect. rotary kiln features in strong structure, stable operation, high-quality products from the kiln, and we can offers advanced efficient shaft preheater, five-grade cyclone preheater.

Technical parameter:

| Specification(m) | φ2.8/2.5×44 | φ3×48 | φ3.2×50 | φ3.3×50 | φ3.5×54 | ||

| Capacity(t/d) | 300 | 600-700 | 1000 | 1200 | 1500-1800 | ||

| Slope of the kiln shell (%) | 3.5 | 3.5 | 3.5 | 4 | 4 | ||

| No.of supporters | 3 | 3 | 3 | 3 | 3 | ||

| Type of thrust roller | Mechanical | Mechanicalor Hydraulic | Hydraulic | Hydraulic | Hydraulic | ||

| Rotary speed of kiln | Main driving (r/min) | 0.445-2.22 | 0.676-3.38 | 0.36-3.57 | 0.36-3.57 | 0.39-3.9 | |

| Auxiliary driving (r/min) | 4.75 | 9.36 | 6.5 | 5.61 | 7.66 | ||

Main driving | Motor | Type | ZSN4-225-21 | Z2-101 | ZSN4-280-191B | ZSN4-280-191B | ZSN4-315-092 |

| Rated power(kw) | 55 | 100 | 160 | 160 | 220 | ||

Seed regulation Range(r/min) | 1000 | 1500 | 1500 | 1500 | 1000 | ||

| Rated voltage(V) | 440 | 220 | 440 | 440 | 440 | ||

| Reducer | Type | ZS145-1-1 | ZS145-1-1 | ZSY-450-40-V | ZSY450-40 | NZS995-28VIBL | |

| Total speed ratio | 49-63 | 50 | 40 | 40 | 28 | ||

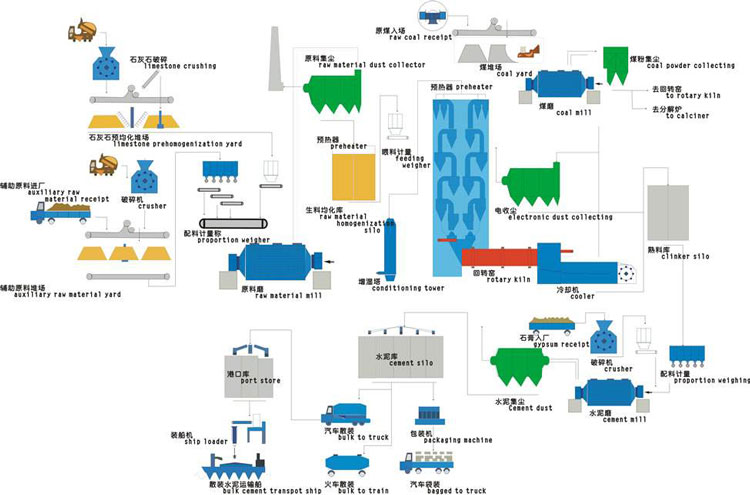

In cement plant, to produce cement need seven steps.

1.Crushing and Preblending

In cement plant, most of the material need to be broken, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material in cement production, after mining the size of limestone is large, with high hardness, so the limestone crushing plays a more important role in cement plant.

2. raw material preparation

In cement plant, producing each 1 ton of Portland cement need grinding at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum). Grinding operation consumes power about 60% of total power in cement plants, raw material grinding takes more than 30%, while coal mill used in cement palnt consumes 3%, cement grinding about 40%. So choosing the right grinding mills in cement plant is very important.

3. raw materials homogenization

Adopting the technology of homogenization could rationally get the best homo-effect and afford an eligible production to the demand

4. preheating and precalcing

Preheater and calciner is key equipment for precalcing production technique.

5.burning cement clinker in a rotary kiln.

The calcination of Rotary Kiln is a key step of cement production , it makes directly influence on the quality of cement clinker.

6. cement grinding

Cement grinding is used for grinding cement clinker (and gelling agent, performance tuning materials, etc.) to the appropriate size (in fineness, specific surface area, said), optimizing cement grain grading, increasing the hydration area, accelerating the hydration rate to meet the requirements of cement paste setting, hardening.

7. cement packing

Cement Plant equipments

In the cement manufacturing plant, not only the crushing machinery, but also the grinding machine is used as cement producing equipment.

|