| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tungsten Carbide Corrugating Rolls |

|---|---|

| Brand Name: | YH |

| Certification: | ISO9001 |

| Place of Origin: | Made in China |

| MOQ: | 1set |

| Payment Terms: | T/T |

| Supply Ability: | 1500 sets per year |

| Delivery Time: | 60-90 days |

| Packaging Details: | Wooden Boxes |

| Material: | 50CrMo precision forged alloy steel |

| Coating: | American Praxair super hard 1342 tungsten cabide powder |

| Coating thickness: | 60-80μm |

| Heating treatment: | Intermediate frequency quenching |

| Hardness: | >HRC58 after hardening |

| Harden Layer: | 8-12mm |

| Micro hardness: | HV1250-1400 |

| Flute type: | B Flute |

| Warranty: | 30-35million linear meters or 1 year, whichever comes first |

| Finishing: | Ra <0.6μm |

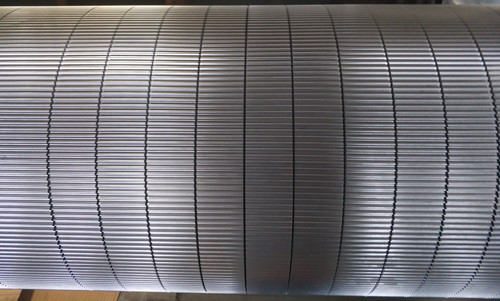

New TC B Flute Corrugated Roller

| Flute | Profile | Height(mm) | Pitch(mm) | Flutes/300mm | T.U.R |

| A | UV | 4.5-5.0 | 8.0-9.5 | 34±3 | 1.45-1.52 |

| C | UV | 3.5-4.0 | 6.8-7.9 | 41±3 | 1.37-1.47 |

| B | UV | 2.5-3.0 | 5.5-6.5 | 50±4 | 1.33-1.41 |

| E | UV | 1.1-2.0 | 3.0-3.5 | 93±6 | 1.24-1.36 |

| F | UV | 0.8-1.0 | 2.2-3.2 | 115±20 | 1.19-1.25 |

| G | UV | 0.6-0.8 | 1.8-2.8 | 136±20 | 1.15-1.20 |

| N | UV | 0.4-0.6 | 1.2-2.2 | 193±55 | 1.10-1.15 |

| Others | UV | Customized | Design | Design | Design |

After making concerted efforts in R&D and manufacturing through many years, Qingdao Meijia has perfectly solved the technical problem that the production loss being caused due to the insufficient quality of corrugating roll.

A. Meijia,in accordance with the different customer needs and on-site situation, has developed special flute type,which circle parabola is adopted for the medium-high outline,solving the problems like collapsed flute,poor lamination,inner liner frothing,heavy scoring on inner liner from the very beginning.

B. Special steel D50CrMo is used as the material to producing corrugating roll.It is the premium alloy precision forging steel featuring stable property and even heat transfer.

C. With scrupulous attitude, Meijia adopted multi-directional detection to enable the parameter of the produced corrugating roll perfectly match that of the designed one. In this way, to keep a smooth and stable operation. The unique tungsten carbide techniques largely improves the abrasive resistance and extend the service of life of corrugating roll. The special polishing method enables the surface finish reach Ra<0.3μm, successfully solving the problem of broken fluting paper owing by its technical defects.

|