| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Track ROV Series |

|---|---|

| Brand Name: | VVLAI |

| Model Number: | VVL-SXZZ1500-H3700 |

| Certification: | CE/FCC/ISO9001 |

| Place of Origin: | Weihai,China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | TT |

| Supply Ability: | 50sets per year |

| Delivery Time: | 90days |

| Packaging Details: | Container |

| Material: | manganese steel |

| Robot size: | 3200 * 1550 * 1880 mm |

| ROV: | Console,Winch,Cable,Underwater robot |

| Application: | Underwater dredging |

| Design weight: | 4200kg |

| Maximum lifting height: | 3.7m |

| Underwater robot: | underwater cleaning,dredge,bridge,Underdrain,rivercleaning |

| Company Info. |

| Shandong Future Robot Co.,Ltd |

| View Contact Details |

| Product List |

Underwater Dredging Robot

Underwater Loading System

VVL-SXZZ1500-H3700

Configuration:

| No. | Item | Model | QTY | Mark |

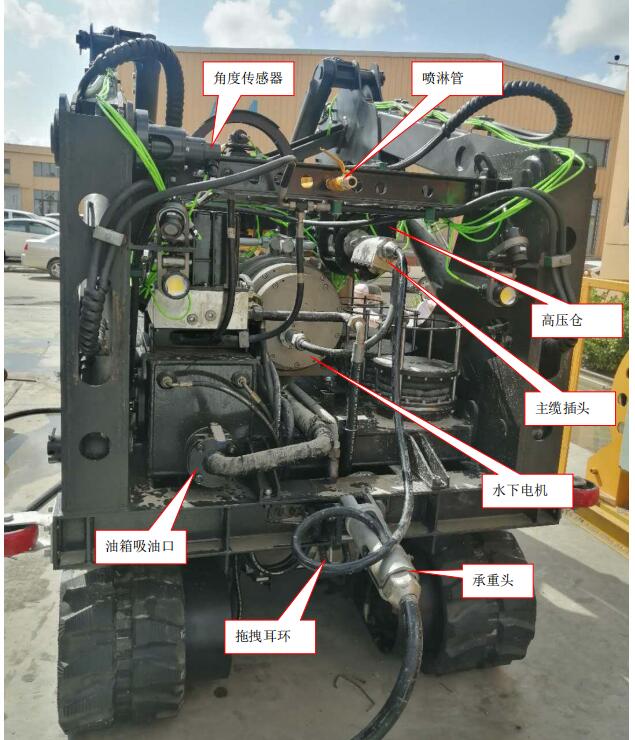

| 1 | Underwater loading robot body | VVL-SXZZ1500-3700 | 1set | The robot body frame is made of manganese steel, including internal hydraulic system, power cabin system, electrical cabin system, hydraulic support, crawler, etc., including lifting support, bearing 8000kg |

| 2 | Underwater visible imaging sonar | M1200d | 1set | For high resolution sonar effect |

3 | 360 ° rotary pan&tilt | VVL-YT-360-1 | 1set | The pan tilt platform can be adjusted by rotation and pitch. Through the angle adjustment, the underwater sludge state can be analyzed and the access path planning can be carried out |

| 4 | Spray cooling device | VVL-LS-1 | 1set | Water pump, middle detachable joint, can be connected to the ground water pipe for cooling |

| 5 | Underwater camera system | VVL-SX-1 | 4set | Including connecting wire, waterproof plug, etc |

| 6 | Underwater lighting system | VVL-ZM-1 | 5set | Including connecting wire, waterproof plug, etc |

| 7 | Adaptive hydraulic cable winch | VVL-YL-1 | 1set | Robot Adaptive hydraulic cable retraction and release system |

| 7.1 | Control cable automatic router | VVL-BX-1 | 1set | The function of automatic cable arrangement saves manual cable arrangement |

8 | Double layer Kevlar control cable | VVL-KL-1 | 300m | The tensile strength is up to 8000kg. The double-layer Kavlar design improves the tensile strength and also greatly improves the wear resistance |

9 | Underwater loading robot control storage integrated cabin | VVL-KC-1 | 1set | Refer to the standard box of about 8m, fix the 4-screen console, fix the cable control system, store the robot, box air conditioner, and adaptive hydraulic cable car track |

| 10 | Hydraulic bucket | VVL-CD1500 | 1set | Length 1.5m replaceable hydraulic bucket |

| 11 | Hydraulic bucket | VVL-CD2000 | 1set | Length 2.0m replaceable hydraulic bucket |

| 12 | Corner conductor of control cable | VVL-DL-1 | 3sets | One group of guide wheel or wire combiner for reducing friction of control cable at culvert corner |

| 13 | Removable crawler gravel grid | VVL-GS-1 | 2sets | Bearing protection to prevent track from entering gravel |

Configuration:

| No. | Items | Configuration |

| 1 | Underwater Loading System |

|

| 2 | Cble winch |

|

| 3 | Console |

|

| 4 | accessories | 1set of 1.5m bucket 1 set of 2m bucket Corner conductor of control cable |

Note

Make sure that 380V alternator above 200kW can supply power to the robot alone, otherwise it will cause irreversible damage to the motor.

Application:

|