| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | DPSS UV Laser |

|---|---|

| Brand Name: | Gainlaser |

| Model Number: | GL-WC-UV05 |

| Certification: | CE |

| Place of Origin: | Shenzhen, China |

| MOQ: | 1 |

| Price: | Please inquire individually |

| Payment Terms: | T/T |

| Supply Ability: | 500 sets per month |

| Delivery Time: | Within 5 days |

| Packaging Details: | Export Wooden Case |

| Laser Wavelength: | 355nm |

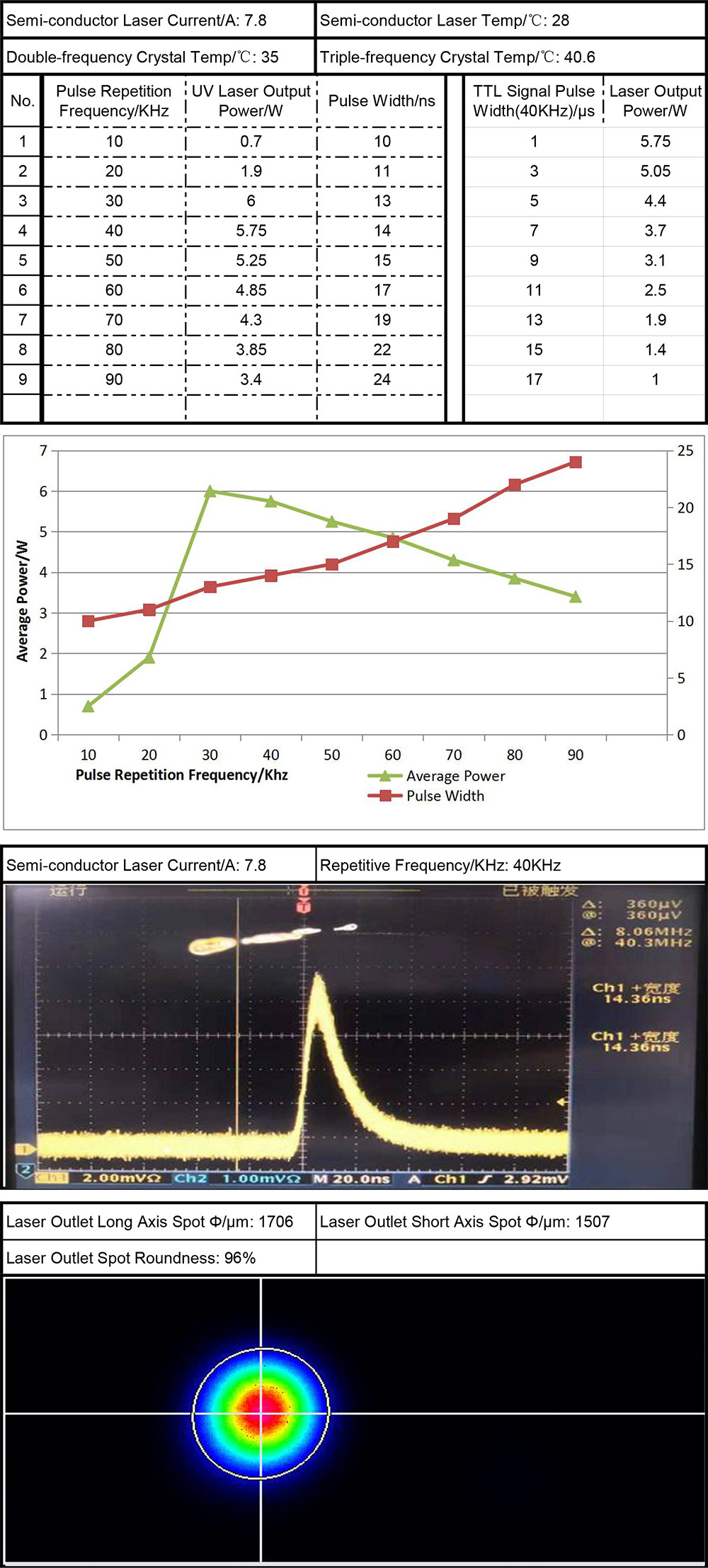

| Average Output Power: | >5W@40KHz |

| Max Pulse Energy: | >0.125mJ@40KHz |

| Cooling Mode: | Water Cooling |

| Pulse Repetitive Frequency: | 1-150KHz |

| Unfocused Beam Frequency: | ≤96% |

UV Laser DPSS Module

1. Product Description

2. What’s UV Laser?

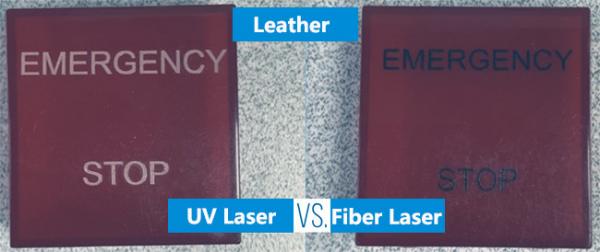

UV Laser is a laser with the short wavelength 355nm to generate an intense energy beam breaking the molecular bonds and vaporize the substrate leaving a permanent mark without contacting the substrate. It is very suitable for sensitive and critical material(such as plastic , leather, etc.) marking with the advantage of its "cold marking" methods. Because it offers a higher absorption rate than fiber and CO2 lasers and are less likely to burn the surrounding material because they produce less heat. This is why UV laser is also referred to as “cold processing method”, while fiber and CO2 lasers are called as ‘thermal processing method’. Fiber / CO2 laser marking machine can alter or even burn some heat-sensitive materials, like plastic, leather, etc. This is because the laser energy is not fully absorbed, allowing too much light to pass through without marking the material. You’re left with indecipherable logos, unreadable barcodes, or damaged parts.

3. Technical Parameter

| Laser Crystal | Nd:YVO4 | Spatial Mode | TEMoo(M2<1.2) |

| Wavelength | 355nm | Polarization Ratio: | >100:1 Horizontal |

| Output Power | >5W@40KHz | 1/e2 Beam Diameter @ Output | 0.6mm |

| Max pulse energy | >0.125mJ@40KHz | Beam circularity | ≤96% |

| Pulse repetition frequency | 10-150KHz | Cooling Mode | Water Cooling |

| Pulse duration | <15ns@30KHz | Ambient temperature | 18℃ - 35℃ |

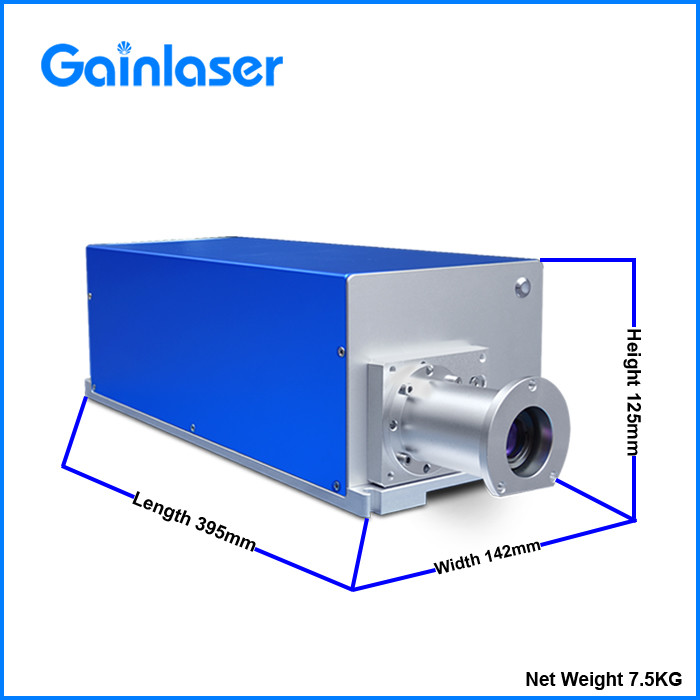

| Pulse-to-pulse stability | <3% | Size | 395*142*125mm |

| Average power stability | <3% | Net weight | 7.5KG |

4. Product Application

1) KN95 Mask Marking

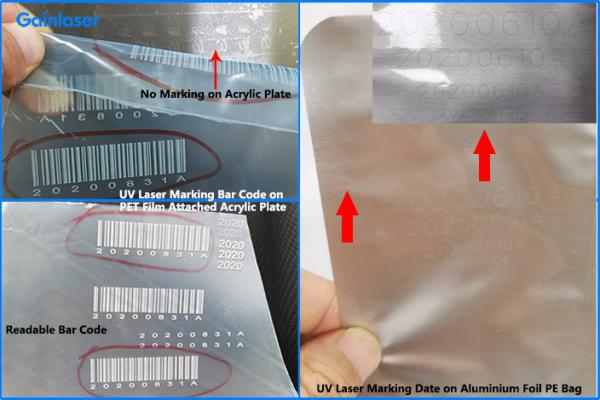

2) Plastic material processing

UV laser can apply to most universal plastic and some engineering plastics, such as PP, PE, PBT, PET, PA, ABS, POM, PS, PC, PUS, EVA, etc., and plastic alloy, like PC/ABS and other material. The marking is clear and bright, and can mark black and white color on natural color plastic, white plastic, colored plastic and black plastic. Successful commercialized application in the plastics include animal ear tag, light switch cover, cosmetic packaging material, vehicle interior button and doorknob, instrument panel, ABS keyboard, HDPE, PET and PVC rigid container and container cover, nylon and PBT automobile and non-automobile electrical connector, engine hood element such as fuse box and air cap, anti-counterfeit labels, container lock catch, stationery, home appliance shell, etc.

2) Glass material processing

Since the focal spot of UV laser is very tiny and processing temperature is low, furthermore as a non-contact marking technology, UV laser is very suitable to mark glass material. Successful UV laser commercialized applications include wine bottle, flavour bottle, drinking bottle and other industries glass bottle package and glass tableware, glass crafts gifts, crystal marking, etc. Besides marking glass directly, UV laser can also remove paint or coat on glass to form text or pattern, like logo, number or other patterns;

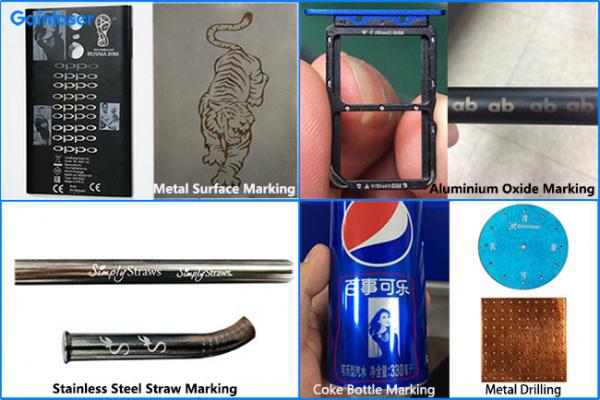

3) Metal Marking

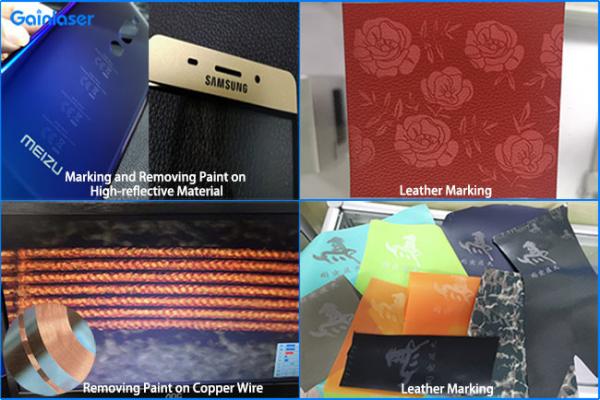

4) Leather Marking

|