| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Concrete Tie Rod |

|---|---|

| Brand Name: | SupFRP |

| Model Number: | T20 |

| Certification: | ISO, SGS, NATA |

| Place of Origin: | Jiangsu, China |

| MOQ: | 3 meters |

| Price: | 1 - 30 USD |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50,000 meters per month |

| Delivery Time: | 1 to 6 weeks |

| Packaging Details: | Packed in bundle with package paper. |

| Name: | SupFRP T20 GFRP Concrete Tie Rod |

| O.D. (mm): | 22 |

| Cross Sectional Area (mm2): | 250 |

| Ultimate Strain: | 2.0% |

| Tensile Load (kN): | 250 |

| Tensile E-Modulus (GPa): | 45 |

| Unit Weight (Kg/m): | 0.71 |

| Length (m): | (1) x 2, x3, x4, x5, x6, x7, x8, x9, x10, x11 |

20mm Fiberglass Cconcrete Form Ties GFRP T Thread Concrete Tie Rod

Features

The GFRP Tie Bar can be widely used to secure concrete formwork when doing concrete placement, it remains in concrete tightening the structure. The GFRP Tie Bar is manufactured in accordance with thread profile of standard steel bars, so related standard accessories can be applied here.

Applications

1. Formwork

2. Fair faced concrete

Advantages

1. Non-magnetic

2. Easy handling

3. Permanent application

4. Cuttability

5. Non-conductive

6. High corrosion resistance

7. Good bond force

8. High end loading

Technical Data

| GFRP Tie Rod | T15/130 | T20/250 | |

| Outside Diameter (mm)*1 | 17 | 22 | |

| Nominal Cross sectional area (mm2)*2 | 130 | 250 | |

| Guaranteed tensile load (kN) | 130 | 250 | |

| Tensile E-Modulus (GPa) | 45 | 45 | |

| Ultimate Strain | 2.0% | ||

| Weight (kg/m) | 0.37 | 0.71 | |

| Length (m) | (1) x 2, x3, x4, x5, x6, x7, x8, x9, x10, x11 | ||

*1 Including Waved Thread Structure

*2 Characteristic Stress Value in core

Product

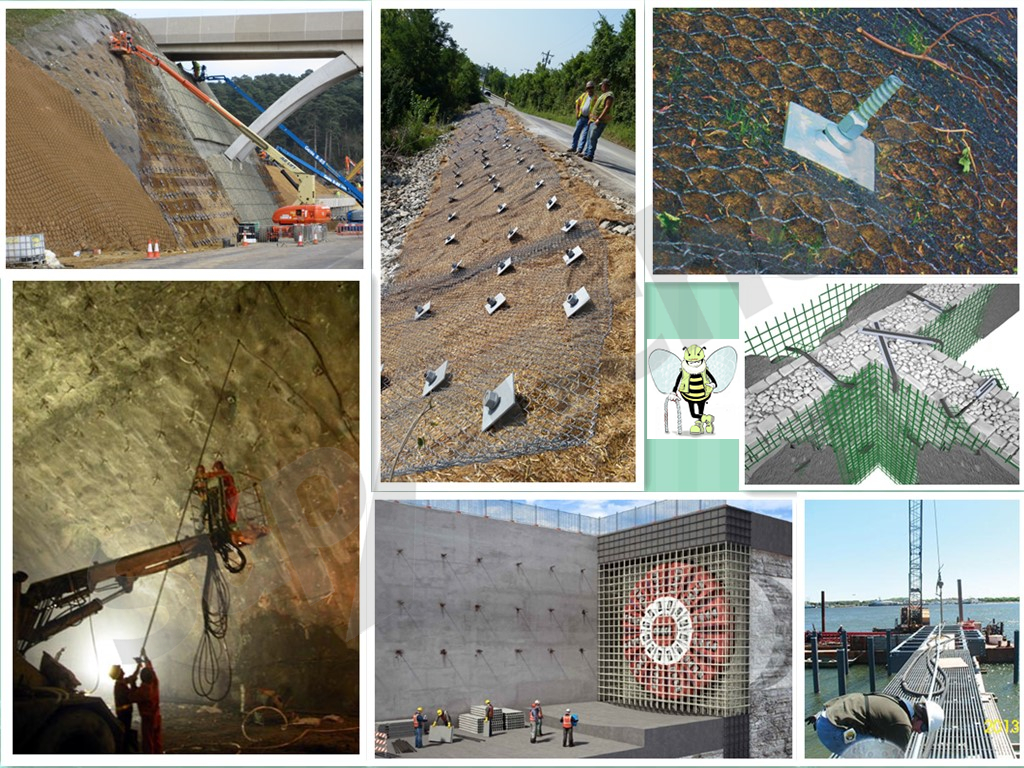

Application

SubNumbers

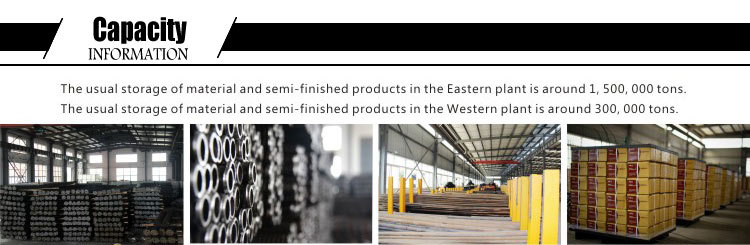

10 Years - The average seniority > 10 years, which is not common in anchor manufacturing industry.

20 Years - 20 years of exporting experience, familiar with different product standards from different

customers and countries.

26 Years - 26 years of exploration and development, SupAnchor has become the No.1 SDA bar

manufacturer in Asia.

60 Countries - customers from 60 countries. Our self drilling anchor systems have been used by

customers from 50 countries all over the world, including America, Chile, Germany,

Australia India, etc.

1,500 Projects - SupAnchor’s products have been widely used in over 1500 massive projects.

|