| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Self Drilling Anchor Bar |

|---|---|

| Brand Name: | SupAnchor |

| Model Number: | R51/D63/L200mm |

| Certification: | ISO, SGS, ITB, IBDIM |

| Place of Origin: | Sichuan, China |

| MOQ: | 3 meters |

| Price: | 1 - 30 USD |

| Payment Terms: | L/C, T/T |

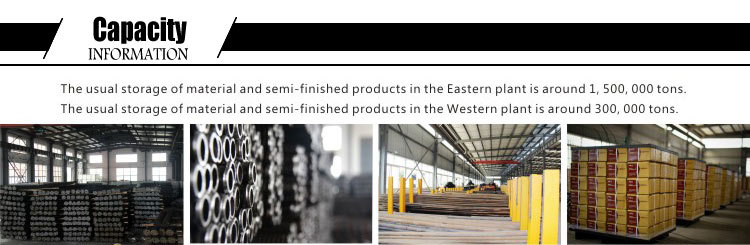

| Supply Ability: | 200,000 meters per month |

| Delivery Time: | 1 to 6 weeks |

| Packaging Details: | Packed in bundle with package paper. |

| Name: | SupAnchor R51/D63/L200mm Self Drilling Anchor Coupler |

| Thread Type: | ISO1720 - R51 / Left or Right |

| Outside Diameter (mm): | 63 |

| Type of Steel: | 40Cr |

| I.D. (mm): | 51 |

| Hardness (HRC): | 20-30 |

| Unit Weight (Kg/m): | 1.90 |

| Length (mm): | 200 |

Features

The self drilling anchor system enables drilling and grouting in one operation, making much saving in jobsite and project time. Anchor coupler is used to connect to anchor bars for deep holes.

Fits SupAnchor® standard Boomer, ROC and Mustang rigs. Particularly suitable for difficult ground conditions.

Technical Data

| Anchor Coupling | R51L/36 | R51L/34 | R51N/33 | R51N/31 | R51/950 | R51/660 | ||||

| Outside Diameter (mm) | 63 | |||||||||

| Length (mm ) | 140 | 140 | 200 | 200 | 260 | 180 | ||||

| Thread type | ISO 1720 - R51 / Left or Right | |||||||||

| Type of steel | 40Cr | |||||||||

| Unit Weight (kg) | 1.26 | 1.26 | 1.90 | 1.90 | 2.46 | 1.68 | ||||

| Hardness | HRC 20-30 | |||||||||

| Options of Anti-corrosion | Hot-dipped Galvanization / Epoxy Coating / SupCoat *Hot-dipped Galvanization: ISO 1461. * Epoxy Coating: Bending properties up to standard ISO 1519; Impact properties up to standard ASTMD 2794; Adhesion up to standard ISO 2409:2007. *SupCoat: HDG + EC | |||||||||

Anchor Bar and Accessories

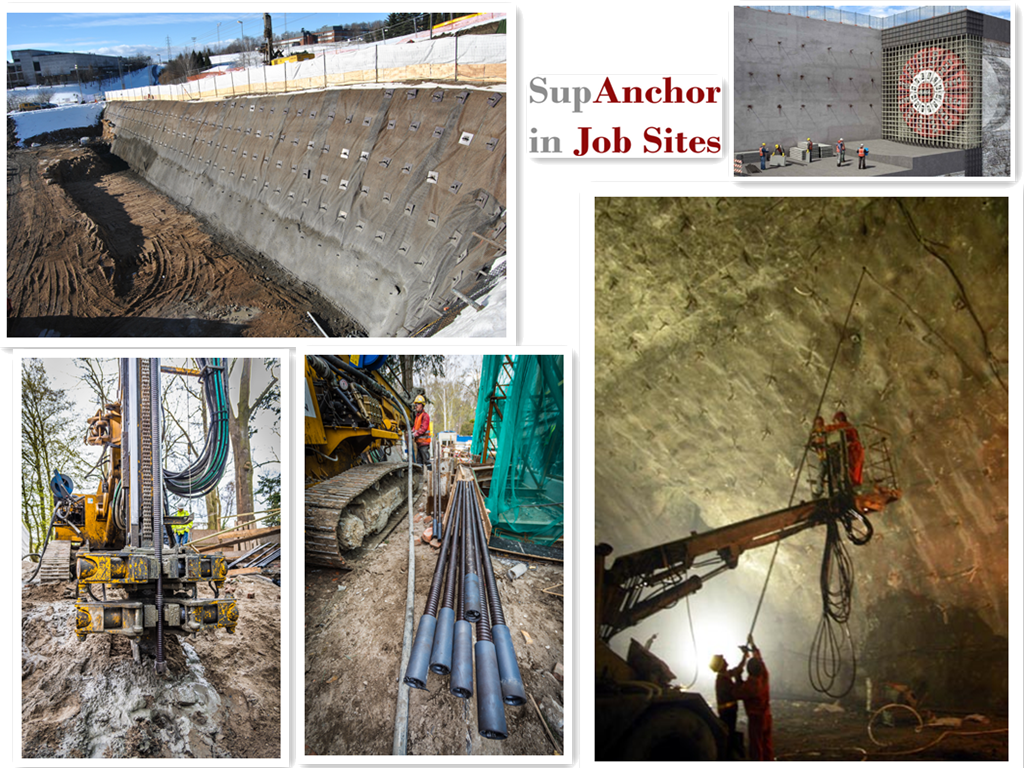

Job sites

SubNumbers

10 Years - The average seniority > 10 years, which is not common in anchor manufacturing industry.

20 Years - 20 years of exporting experience, familiar with different product standards from different

customers and countries.

26 Years - 26 years of exploration and development, SupAnchor has become the No.1 SDA bar

manufacturer in Asia.

60 Countries - customers from 60 countries. Our self drilling anchor systems have been used by

customers from 50 countries all over the world, including America, Chile, Germany,

Australia India, etc.

1,500 Projects - SupAnchor’s products have been widely used in over 1500 massive projects.

| Mechanical strength test ratio | >= | 3% |

| Dimensions test ratio | = | 100% |

| Surface inspection ratio | = | 100% |

|