| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Insulating Glass Production Line |

|---|---|

| Brand Name: | LIJIANG GLASS |

| Model Number: | LJBZ2535G |

| Certification: | CE |

| Place of Origin: | JINAN, CHINA |

| MOQ: | 1set |

| Price: | Negotiable |

| Supply Ability: | 20 sets per month |

| Delivery Time: | 60days |

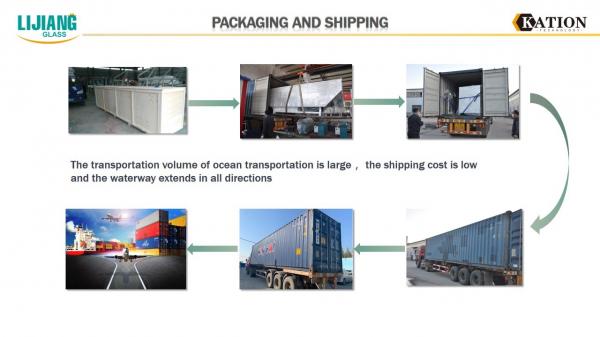

| Packaging Details: | Container |

| Production nam: | Automatic Insulated Glass Processing Line |

| Max filling gas size: | 2500*3200mm |

| Application: | Double Glass , Triple Glass |

| Control: | PLC Control |

| Insulating glass thickness: | 60mm |

| Motor: | Simens |

| Gas content: | >90% |

Main Features:

Overview of Automatic Insulated Glass Production Line

The main goal of the Insulated Glass production line is to create high-quality products, bring the latest production technologies to customers, improve production efficiency, save production costs and maximize benefits.

Details of Insulating glass Production line

• 01 transfer section

Automatic detection of offline Low-e film

• 02 washing section

Advantages:

• Prewash (optional)

• Low-e bottles can be washed using 3 pairs of soft, 0.1 mm soft-haired brushes

• Uses the new Duckbill Air Knife, the size of the air outlet is controlled by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid air resonant resonance.

• The air blade can automatically adjust the width of the air blade according to the thickness

• Actuator box with wash speed display accurately displays wash speed (8-10 m)

• Water tank automatic temperature control, water filling system

• Stainless steel material

• European silencing system

• 03 discharge section

• Storage glass

• 04 inspection and installation section

The new structure of this section is changed to an inline beam lifting structure (double beam). It is easy to inspect and wipe the glass.

• 05 transfer section

Automatic measurement of glass thickness. It can be used according to actual needs when working.

• 06 pressing and filling section

Advantages:

• Adopts conveyor belt to transfer glass, uses servo motor to press glass

• Ultra-long (2500mm*3500mm) insulating glass can be compressed twice

• The pressing plate can be opened for easy maintenance

• Pressing board with adjustable structure to guarantee long-lasting service life

• Automatically fill argon gas with significant sealing effect, higher argon content

Quick response sensor for constant control of the filling gas filling process

You can set the gas value and show the gas filling process on the touch screen

Concentrated gas concentration is greater than 90%

Adjust the zones to fill the glass of different sizes with the post-stamping method, thus reducing argon loss

No need to drill holes in the spacer frame

Gas is a stable gas argon gas

7 07 Vacancy Section

Glass storage glass

A can be attached to the sealing machine

Electrical parameters

| NAME | ORIGIN | BRAND |

| Servo motor | Germany | SIEMENS |

| PLC | Germany | SIEMENS |

| Low voltage electrical appliance | Germany | SIEMENS |

| Frequency converter | Germany | SIEMENS |

| Transfer motor | Taiwan | LINHAI |

| Brush motor | Taiwan | LINHAI |

| Water pump | China | LINGXIAO |

| Guide | Taiwan | HIWIN |

| Pneumatic Components | Taiwan | AIRTAC |

| Electric gauge | China | MIRAN |

| Photoelectric switch | Germany | SICK |

| Micro Switch | Taiwan | TEND |

| Button and indicator light | France | SCHNEIDER |

| touch screen | Taiwan | WEINVIEW |

| Intermediate relay | Japan | OMRON |

| Insulating Glass Production line with gas filling online | ||

Tech parameters

| Max. glass size | 2500mm*3500mm |

| Max glass size for filling gas | 2500mm*3200mm |

| Min. glass size | 280mm*450mm |

| Glass thickness | 3-15mm |

| Insulating glass thickness | 60mm |

| Glass washing speed | 2-10m/min |

| Glass conveyor speed | 45m/min |

| Washing brushes | 3 pairs of soft brushes with 0.1mm hair |

| Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

| Air supply | Flow: 0.8m/min |

| Air pressure | ≥0.8MPa |

| Total power | 3P 380V 50HZ 40KW |

| Dimension | 23500*3500*3700mm |

| Weight | 6500kg |

|