| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Extruder Machine Parts |

|---|---|

| Brand Name: | Joiner |

| Certification: | ISO 9001 2005 |

| Place of Origin: | China |

| MOQ: | Negotiation |

| Price: | Negotiation |

| Supply Ability: | 1000 pieces/per month |

| Delivery Time: | 60 days |

| Packaging Details: | Wooden box |

| Model Number: | As request |

| Material: | Wear / corrosion resistance |

| Heat treatment: | Vacuum Quenching |

| Surface treatment: | Sand Blast/polishing |

| Hardness: | HRC 58-62 |

| Application: | Twin Screw Extruder |

| Condition: | New |

| Standard: | DIN, GB, etc. |

| Technics: | Machining |

| Company Info. |

| Joiner Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Capacity Double Screw 2-Flighted Square Keyslot Vacuum Quenching Extruder Screw Elements

| Screw Design | Double-Screw |  |

| Hardness | 58-60HRC | |

| Brand Name | Jioner | |

| Surface Treatment | Polishing/Sand Blasting | |

| Materials | 6542/SAM39/WR5/WR14 ect. | |

| Place of Origin | Sichuan, China | |

| Warranty | 6 months | |

| Screw Range | Φ 15.6 - Φ 400mm | |

| Suit For | Pharmaceuticals Extrusion Chemical Extrusion Food Extrusion Powder Coating Extrusion | |

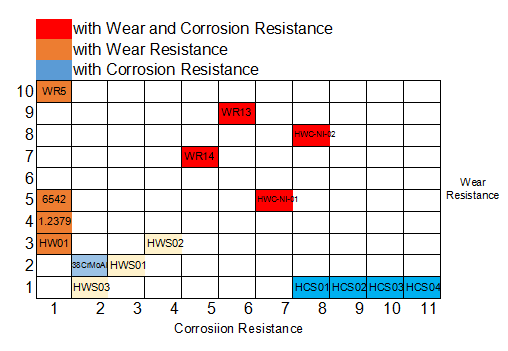

2. Screw Elements Materials:

3.Series Extruder Screw Elements

| Special Screw Segment | Convey Screw Element |

| Mixing Screw Element | Kneading Block and disk |

| Transition Screw Element | Screw Element for Side Feeder |

| Screw Element for Side Feeder |

4. Process of making

5. Heat treatment

As we all know, heat treatment is very important in the screw

production process. In order to ensure the quality of products,

Joiner has purchased professional heat treatment equipment to

produce, so that we can control the construction process by

ourselves. In China, we are the only company that does heat

treatment by ourselves, and the heat treatment of screw components

made by Nanjing factory is processed by outsiders, so the quality

of products can not be completely guarantee.

6. Packing Details:

According to your order quantities and products sizes to choose wooden boxes or cartons to pack:

7. Testing Reports

We will send Inspection reports for every our customer.

1).General Dimension Inspection Report

2). Material certificate for customer.

8. Product photos:

|