| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Bimetallic Wear Bars |

|---|---|

| Place of Origin: | Hunan, China |

| Brand Name: | VIBO, Domite, OEM |

| Certification: | ASTM |

| Supply Ability: | 200 Ton/Tons per Month |

| Packaging Details: | Polywood crates, polywood pallets, Anti-rust film |

| MOQ: | 500 Kilogram/Kilograms |

| Price: | $5.00 - $8.00 / Kilogram |

| Warranty: | unavailable |

| Applicable Industries: | Energy & Mining |

| Local Service Location: | None |

| Showroom Location: | None |

| Type: | shaped wear bars |

| Machine Type: | crusher bucket excavator |

| Material: | ASTM 532 |

| Processing Type: | Casting |

| Use: | Ore Mining |

| Hardness: | 63HRC |

| Shearing Strength: | 210Mpa Min |

| Impact Toughness: | Up to 150J/cm2 |

| size: | 202x25x35mm |

Abrasion Resistant 202x25x35mm / 244x25x35mm Bimetallic Wear Bars

| Product Description |

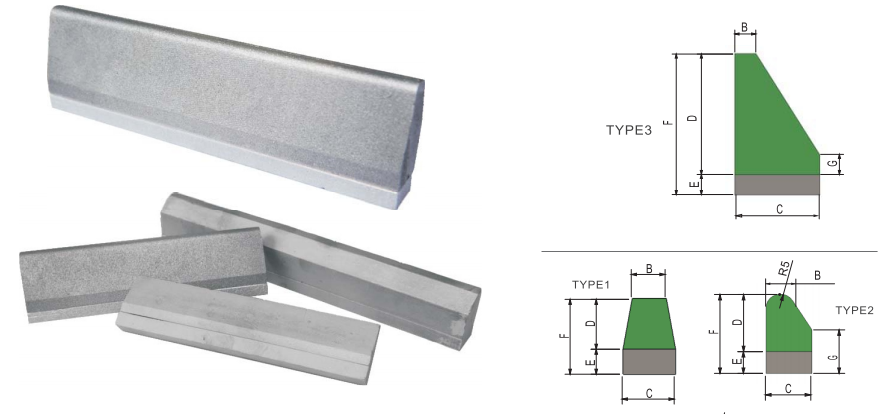

Chrome carbide bimetallic shaped wear bars for mining industry

We are involved in Manufacturing and Exporting Shaped Wear Bars. The products offered by us are the ultimate choice of the customers. Wear Blocks combine is a combination of high chromium white iron metallurgical bonded to a mild steel backing plate. The white iron has a minimum hardness of 700 Brinell (63 Rc) providing maximum abrasion resistance protection for your equipment. The mild steel is easily weldable with minimal preparation and acts as a cushion for the white iron, enabling it to handle impact and abrasion in the most extreme applications. Lamination of chrome moly white iron metallurgically bonded to a mild steel backing plate achieving a high strength joint. Its bonding shear strength is over 30,500 psi (or 210 Mpa) and will not separate.

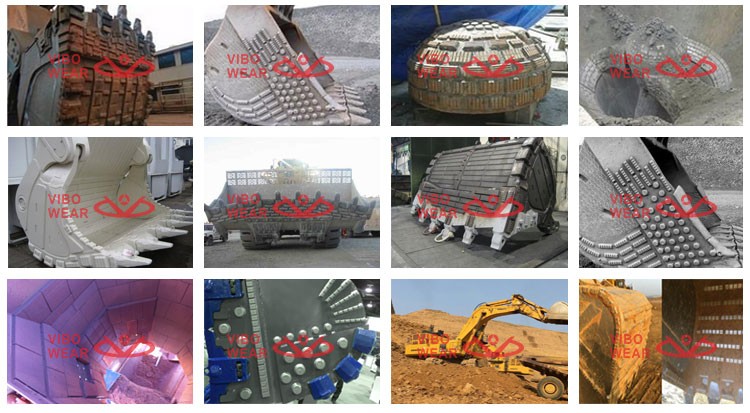

Wear Blocks combine has established a reputation as the solution for impact and high abrasion in the mining and quarry industries, and has numerous applications in the sugar cane, recycling, cement, mineral processing and dredging industries among others. Custom Wear Blocks combine parts can be designed to usera s specifications. White iron: modified AS2027 20/3 Cr Mo with finished minimum hardness of 700 HB (63 Rc) and containing primary carbides up to 1500HV.

Wear Blocks combine can be designed according to your demands. They prevent gouging wear, enabling your buckets and machines to run far longer a with significantly less maintenance required.

Product Dimensions

| Part No | Type | Size(mm) | Dimensions(mm) | Unit Weight(kgs) | ||||||

| A | B | C | D | E | F | G | ||||

| VSB1200 | 1 | 200x20x30 | 200 | 13 | 20 | 20 | 10 | 30 | 0.8 | |

| VSB1244 | 1 | 244x25x35 | 244 | 10 | 25 | 25 | 10 | 35 | 1.4 | |

| VSB1202 | 1 | 202x25x35 | 202 | 10 | 25 | 25 | 10 | 35 | 0.9 | |

| VSB2275 | 2 | 275x16x29 | 275 | 5 | 16 | 21 | 8 | 29 | 16 | 0.9 |

| VSB3150 | 3 | 150x40x70 | 150 | 10 | 40 | 60 | 10 | 70 | 20 | 2.4 |

| VSB3200 | 3 | 200x25x59 | 200 | 3 | 25 | 47 | 12 | 59 | 1.3 | |

| VSB4125 | 4 | 125x40x90 | 125 | 10 | 70 | 80 | 10 | 90 | 4.3 | |

| VSB4200 | 4 | 200x25x50 | 200 | 10 | 25 | 38 | 12 | 50 | 1.5 | |

Product Drawing

| Product Categories |

| 1. Chocky Bars and Blocks | 2. Wear Bars and Blocks | 3. Shaped Wear Bars |

| 4. Wear Buttons & Donuts | 4. Knife Edges | 6. Shredder Hammer Tips |

| 7. Skid Bars | 8. Wear Plates | 9. Grizzly Bars |

| 10. Chocky Rockbox Liners | 11. Dozer Blade | To View More |

| Company Profile |

VIBO Wear is a professional manufacturer of bimetallic composites and dozer blade, which focuses on wear solutions. VIBO factory covers 30000 square meters, and owns complete state-of-the art production line with capacity of 2000tons bimetallic wear parts and 6000tons dozer blade. Attributed to strong R & D ability, high quality and good service, VIBO sproducts have been widely distributed throughout America, Chile, Brazil, Australia, Canada, Russia, South Africa, as well as many other countries and areas. If you are looking for high quality wear-resistant parts,please feel free to contact us with any query, we are ready at your service at any time.

| Team & Exhibition |

| Product Application |

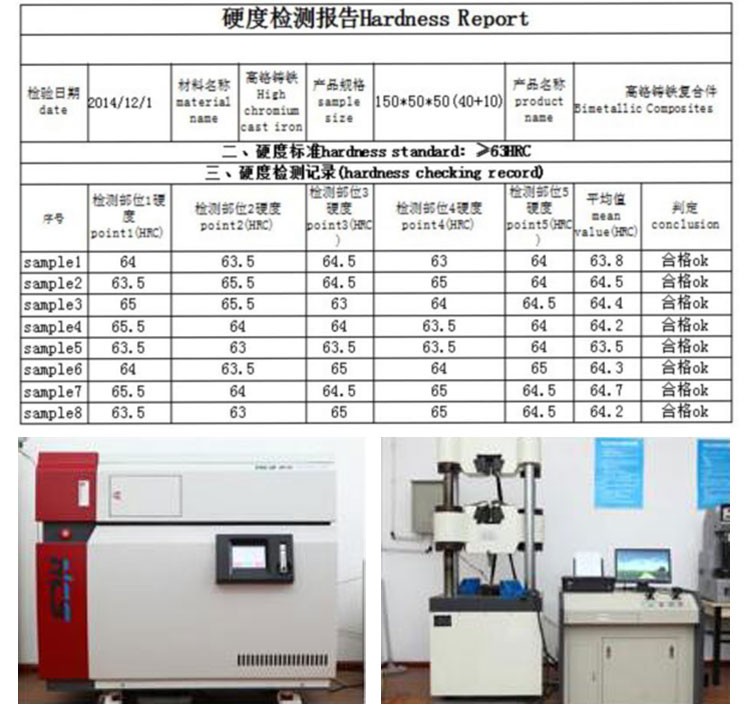

| Quality Control |

In order to ensure wear parts quality,VIBO executes strict quality control procedure in each step of producing. Before shipment,VIBO all products must pass checking at least including chemical, hardness, strength, ultrasonic, microstructure, visual and inspection report will be submitted to customer at the same time.

VIBO commit to replace defective goods 100%.

| Payment & Shipping |

PAYMENT Standard payment terms: 30% T/T deposit,balance against the copy of B/L More payment terms could be provided (LC/DA/DP PAYPAL WESTERN UNION) |  |

| |

SHIPPING Delivery time: 15 days after deposit payment received(based on order quantity) Packing: Plywood box or customized packing as your request. | |

| FAQ |

| Q: Are you a trade company or a manufacturer ? |

| A: We are ISO9001:2008 Certificated factory. |

| Q: Can you provide samples ? is it free or extra ? |

| A: Yes, we can provide free samples for customer’s testing. |

| Q: Can I have my logo in your product ? |

| A: Yes, OEM and ODM are available for us. |

| Q: Can I have a visit to your factory before the order ? |

| A: Sure,welcome to visit our factory . We can pick you up in the airport. Hotel booking service is available. |

|