| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | SS Hydraulic Control Line Tubing |

|---|---|

| Brand Name: | TIPTOP |

| Model Number: | 2507 |

| Certification: | ISO 9001 |

| Place of Origin: | CHINA |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 1000 tons per month |

| Delivery Time: | 10 days |

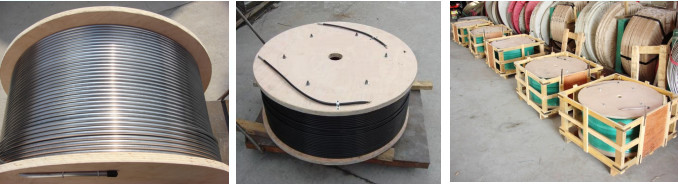

| Packaging Details: | Seaworthy wooden cases or wooden reels |

| Material: | 2507 |

| Standard: | ASTM A789 |

| Length: | According to the sizes |

| Processing: | Bending, Welding, Cutting |

| OD: | 1/16"~1" |

| Thickness: | 0.02"~0.083" |

| Company Info. |

| Xi'an Tiptop Machinery Co.,Ltd |

| View Contact Details |

| Product List |

2507 Super Duplex is a high-alloy duplex stainless steel with a PRE (Pitting Resistance Equivalent) value of minimum 42.5. The grade is characterized by very good chloride corrosion resistance, combined with very high mechanical strength. It is particularly suited for aggressive environments such as warm chlorinated seawater and acidic, chloride containing media. It is widely used in offshore oil and gas exploration and in heat exchangers in petrochemical processing. It's also suitable for hydraulic and instrumentation applications in tropical marine environments.

UNS: S32750

Stock Sizes: 1/8" ~ 1: OD

Specifications:

Seamless Tube: ASTM A789

NACE MR0175/MR0103

Available Processing: Cold Worked and Bright Annealed

Common Testing: Eddy Current, Flare, Flattening, Positive Material Identification

Super Duplex 2507 shows its superior performance in a variety of aspects:

We are specilized in providing high quality laser seam welded corrosion resistant alloy coiled tubing for a variety of downhole and offshore applications

including extremely long length coiled tubing. Applications as below:

| Chemical composition,% | |||||||||||

| Material | Standard | C | Mn | P | S | Si | Ni | Cr | Mo | N | Cu |

| 2507 | ASTM A789 | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 6.0-8.0 | 24.0-26.0 | 3.0-3.5 | 0.24-0.32 | 0.50 |

Size Chart:

| OD | Wall (inch) | Materials | Standard | Working Pressure (MPa) | Length |

| 1/8" | 0.02,0.028,0.035 |

(UNS S32750) | ASTM-A 789 | 60-120 Mpa | Customized |

| 3/16" | 0.02,0.028,0.035,0.049 | ||||

| 1/4" | 0.02,0.028,0.035,0.049,0.065.0.083 | ||||

| 5/16" | |||||

| 3/8" | |||||

| 1/2" |

|