| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Thermal Evaporation Coater |

|---|---|

| Brand Name: | ROYAL |

| Model Number: | RTEP1600-HMDSO |

| Certification: | CE |

| Place of Origin: | Made in China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 6 sets per month |

| Delivery Time: | 12 weeks |

| Packaging Details: | Export standard, to be packed in new cases/cartons, suitable for long-distance ocean/air and inland transportation. |

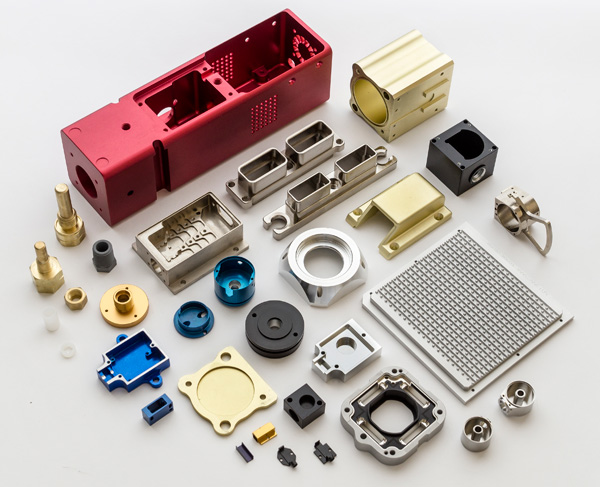

| Application: | Automotive plastic exterior/interior trims Vehicle lighting and components Commercial, industrial and residential LED lighting reflectors Cosmetic packages |

| Substrate materials: | PC, PP, ABS, PC+ABS, PMMA, PSU, PPS etc. |

| Deposition materials: | Aluminum, copper, Ni/Cr etc. |

| Deposition sources: | Tungsten basket, crucible, filament etc. |

| Factory Location: | Shanghai city, China |

| Worldwide Service: | Poland - Europe; Iran- West Asia & Middle East, Turkey, India, Mexico- South America |

| Training Service: | Machine operation, maintenance, coating process Recipes, program |

| Warranty: | Limited warranty 1 year for free, whole life for machine |

| OEM & ODM: | available, we support tailor made design and fabrication |

| Company Info. |

| SHANGHAI ROYAL TECHNOLOGY INC. |

| Verified Supplier |

| View Contact Details |

| Product List |

Royal Technology has designed, built and installed over 100 sets of thermal evaporation coating systems worldwide, encompassing a variety of applications and industries, such as:

Only to name a few, in many other areas PVD vacuum metallizing processes are continue to be used and developed in the coating industry.

Royal Technology- High Vacuum Metallizing Equipment

—–Large Batch, Fast Cycle, High Yield

PVD Vacuum Metallization Process

The whole process is quick and highly improves the quality and beauty of materials.

Benefits

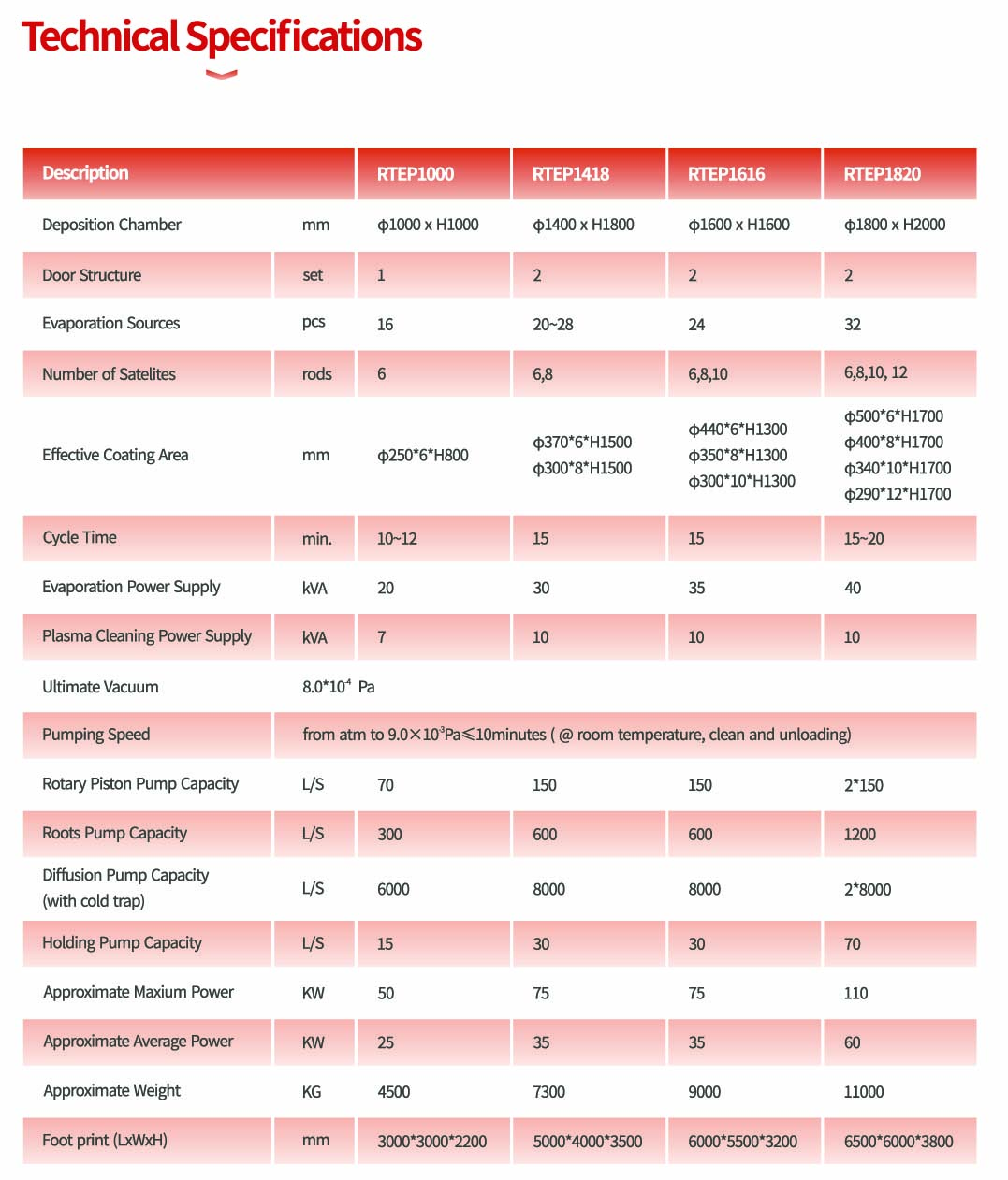

Royal Technology provides small, medium and big size models for your option, you can always find the proper one with our technician’s assistance.

|