| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Grinding Balls For Ball Mill |

|---|---|

| Brand Name: | ZW |

| Model Number: | GB/T 17445-2009 |

| Certification: | ISO9001:2008 SGS |

| Place of Origin: | CHINA |

| MOQ: | 10/tons |

| Price: | Negotiable |

| Supply Ability: | 50000 tons/year |

| Delivery Time: | 7-14 days |

| Packaging Details: | container bags or steel drums |

| Breakage Guarantee: | no break |

| HRC: | 45-48 |

| Quality system authentication: | ISO9001:2008/SGS TEST REPORT |

| Endurance Test Times: | ≥10000 |

| Microstructure: | M+B+C |

| Product name: | low chrome cast ball |

| Company Info. |

| Jinan Zhongwei Casting And Forging Grinding Ball Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Cast Steel Balls Are Made Of A Variety Of Chemical Components

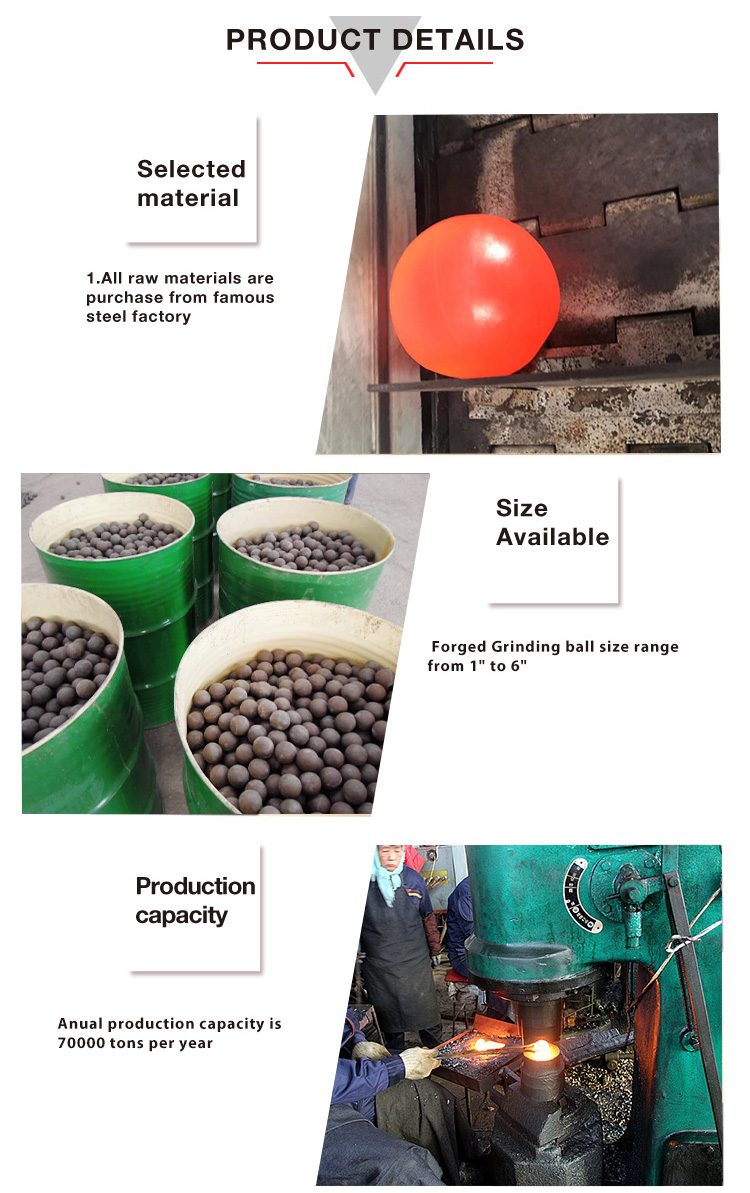

Electric furnace smelting:All cast steel balls are produced by intermediate frequency electric furance .The purity and stability of materials are effectively esured after unform temerature conditioning and twice hot metal purification.

Specifications of our products as follows:

Type and Chenical Composition of Cast Balls

|

| Chemical Composition | ||||||

| C | Si | Mn | S/P | Cr | HRC | |||

| Cast ball | special hi-cr | 2.0-3.2 | <1.0 | 0.5-2.0 | <0.06 | >18 | 58-64 | |

higt-cr | 2.0-3.2 | <1.0 | 0.5-1.5 | <0.06 | >10 | 58-62 | ||

| 2.0-3.2 | <1.0 | 0.5-1.5 | <0.06 | ≥5 | 45-48 | ||

| 2.2-3.4 | ≤1.2 | 0.5-1.5 | ≤0.06 | 1.0-1.5 | 42-46 | ||

Physical property of cast iron balls

Name | Material | Impact test AK.j/cm^2 | Endurance test times | HRC | Breakage |

Cast ball | special hi-cr | ≥4 | ≥10000 | 58-64 | <1% |

| higt-cr | ≥3 | ≥10000 | 58-62 | <1% | |

| medium-cr | ≥3 | ≥8000 | 45-48 | <1% | |

| low-cr | ≥2 | ≥8000 | 42-46 | <1% |

Assay before furnace :Temperature control is an important and complex process during cast steel ball production.Different tapping temperature and heat temperature are sensitively reflected in the quality of the products.It is requested to master the proper pouring temperature ,mold temperature ,so that can make sure the products achieve a good state of body tisssue during the transition from Liquid to solid states.

Process features of cast iron balls:

Moulding process---pouing when the molten iron temoerature reaches

1500 C,using the teoperature difference between moletn iron and the

molds.in this way,the ball can achieve internal organization of

grain refinement and be moredense.menanwhile,the carvide is

radially arranged .and such carbide is embedded in the matrix again

during grinding process,forming hatd layer continously,so that the

hardness and toughness is maintained to a reasonable range,greatly

improving the toughness and hardness of the grinding balls.

We are one of the largest factory specialized in producing Forging Grinding Media Ball, Rolling Grinding Media Balland Casting Grinding Media Ball in China. It was founded in 1988, located in Zhangqiu City, Shandong Province, China. Annual Production Capacity is 50,000 metric ton. There are 120 employees, covering an area of 15,000 square meters. Our products have been exported to more than 30 countries and got a lot of praise. We have large-scale production workshop, advanced production equipment and perfect quality assurance system. Our company has passed ISO9001:2000 quality system authentication and we always keep sincere service promise.

Package: Steel drums (850kg per drum) or Flexible Container Bags ( 1000kg per bag)

|