| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Insulating Glass Production Line |

|---|---|

| Brand Name: | Lijiang |

| Model Number: | LJXJ800 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable, |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20set/month |

| Delivery Time: | 10days |

| Packaging Details: | wooden case or container |

| Name: | Glass Cantilever Crane |

| Advantage: | with lifting sucker |

| Max lifting weight: | 800KG |

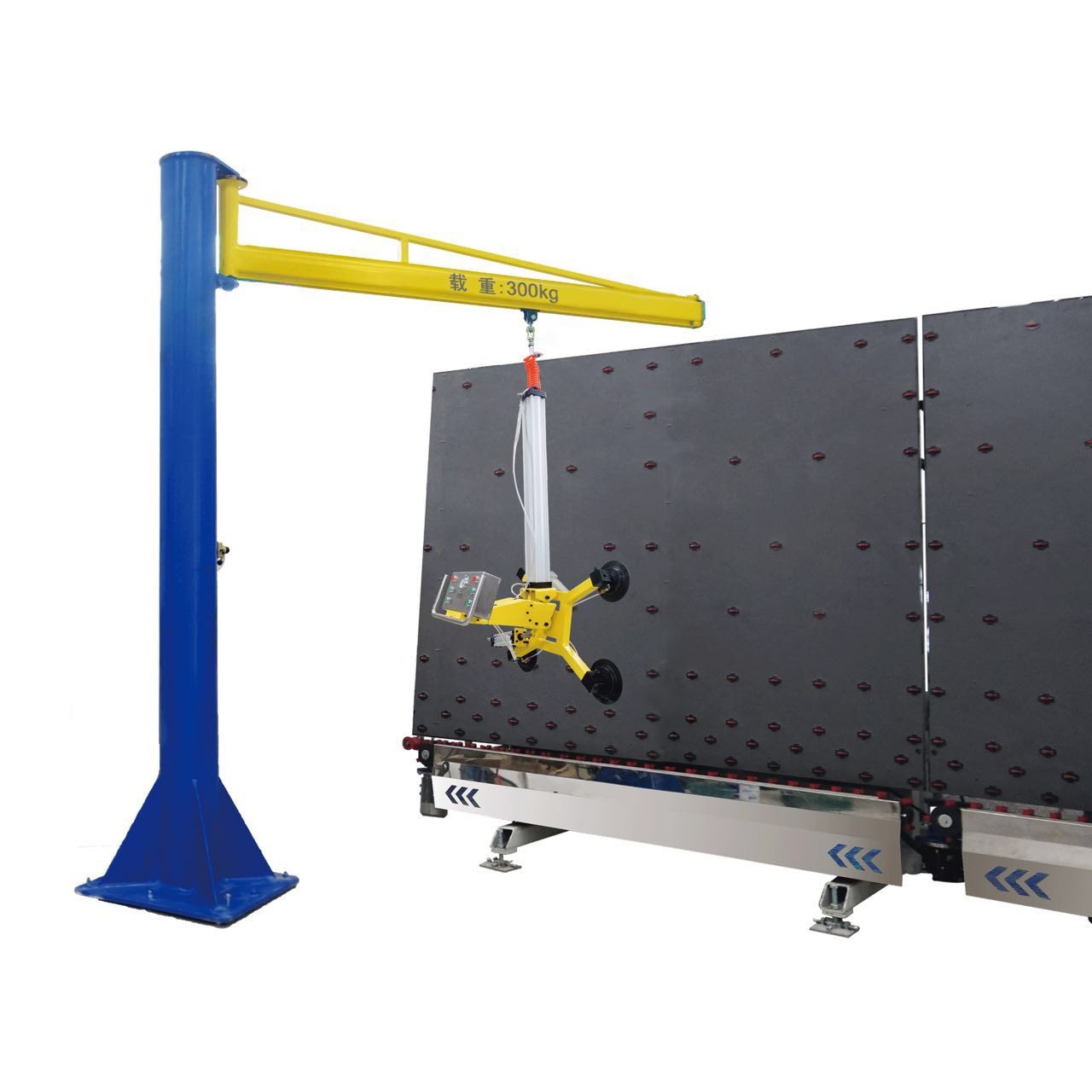

Customization Glass Cantilever Crane with four lifting suckers 800KG LJXJ800

Glass Cantilever Crane with lifting sucker

1. This vacuum glass lifter is for handling insulating glass sheet.

2. This glass lifter is able to lift the glass sheet with 800kg

3. It is equip with 5 suckers. But the sucker can be add according

to need of the client.

4. The equipment is Stable, Easy to use and safe.

5. The vacuum lifter is equipped with a warning light in case of a

power failure or vacuum leakage, an optical and an acoustic signal

goes off immediately to warn the operator to do emergency

operation.

Parameters:

| Max Glass weight | 800KG | |

| Rotation angle | Rotate 180 | Left and Right Up and Down |

| Suction cups | 4 Pieces | |

| Cup Materials | Silicone | |

| Sliding method | Manual | |

| Column height | 4 meters | Gas storage function |

| Arm length | 4 meters | |

| Air Control parts | Airtac |

Useing For

- Insulating Glass Production line,

- Installing Glass Curtain Wall System,

- Loading and Unloading glass sheet on glass cutting table,

- Instaling car windscreen.

Automatic Aluminum Spacer Bending Machine LJZW2020

Main feature

• Adopt Siemens PLC control system, touch screen interface

• Japan FUJI CNC servo control system

• Four spacer size storage units

• Automatically cut and feed aluminum spacers

• Auxiliary function of adjustment for bending large aluminum frame

• Aluminum spacers are available in different sizes and sizes

• Bend shaped spacer frames continuously

• Separated guard board outside of bender

• Automatically avoid the connection while bending and cutting

• Pause and Reset device for handling equipment failures

• USB input function, read the excel format file directly etc (Optional)

• Spacer printing code function (Optional)

• Printing label sticker function (Optional)

• Can bend aluminum spacer and stainless steel ( Optional)

• Automatic drill gas filling hole (Optional)

• Connect to ERP system (Optional)

Technical data

| Max. bending size | 2000mm*2000mm (2500*2500mm) |

| Min. bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Electrical parameters

| NAME | BRAND | NAME | BRAND |

| PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

| Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

| Servo motor | JAPAN FUJI | Solenoid valve | Taiwan AIRTAC |

| Servo driver | JAPAN FUJI | Switch power | Taiwan TEND |

| Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

| Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

|