| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Medical Injection Mold |

|---|---|

| Brand Name: | KYE |

| Model Number: | OEM |

| Certification: | ISO9001:ISO14001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | To Be Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 50 Sets Mould Per Month |

| Delivery Time: | 30-50 working days |

| Packaging Details: | Wooden Case With Steel Frame |

| Mould type: | 2 Plate-mold/3 Plate-mold |

| Part Mateiral: | Mecical/Food grade silicon |

| Mold material: | P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Mold base material: | S50C LKM, DME, LKM & HASCO & DME, HASCO, LKM Mould Base |

| Surface requirement: | EDM,VDI 3400 Code ,MOLD-TECH, Texturing,Cavity ,Core Finishing,High Polish, Mirror Face, Grade 3 Diamond, Paper Finish, Stone Finish. |

| Cavity number: | single or multi- cavity |

| Mold life: | 1,000 to 1,000,000 shots(according to your requirement) |

| Usage: | Custom plastic parts, plastic injection mould |

| Company Info. |

| KYE Mould Techenology Limited |

| View Contact Details |

| Product List |

Food Grade Silicon P20 2311 H13 2344 Medical Injection Mold

Product Details

| Plastic materials | PBT, PC, POM, PA66, PBT+GF30%,PS, ABS, PP, PVC, PMMA, ,Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality | ROSH and SGS standard |

| Size | According to your drawing |

| Mould Base | S50C HASCO standard, European standard, World standard |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finishing | Texture (MT standard), high gloss polishing |

| Cavity / Core material | P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity Number | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip,etc. |

| Mould Life | 1,000 to 1,000,000 shots(according to your requirement) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Package | Standard Artificial Wooden Box with Steel Frame |

| Mold building lead time | 30~50 days after mold 3D approved, parts measurement report (upon required). |

| Annual production | 300-400 sets of mold |

| Plastic materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%,Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality | ROSH and SGS standard |

| Size | According to your drawing |

| Mould Base | S50C HASCO standard, European standard, World standard |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finishing | Texture (MT standard), high gloss polishing |

| Cavity / Core material | P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity Number | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip,etc. |

| Mould Life | 1,000 to 1,000,000 shots(according to your requirement) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Package | Standard Artificial Wooden Box with Steel Frame |

| Mold building lead time | 30~50 days after mold 3D approved, parts measurement report (upon required). |

| Annual production | 300-400 sets of mold |

KYE is a professional plastic injection molding company since 2009. We provide high-quality, low-cost plastic injection mold tooling and custom plastic molded parts to customers all over the world. We provide custom plastic injection molding and parts at a very competitive cost.

KYE Mould satisfies our customers’ plastic injection molding needs with quality and speed. Whether you need a plastic injection molding company to build your plastic molding tool and plastic parts, or if you need an export mold to produce plastic parts in your own facility, we’re ready to get the job done with good quality and service.

Manufacture Capabilities

1. New project/design development assistance, base on customer’s samples or design drawing;

2. When the customer encounter bottleneck, give them some technical assistance;

3. Help the customer complete the 3D design drawing;

4. Simulate the effect of the product by simulation software and offer the simulation report;

5. Test Mold: Test Mold and Sample Making;

6. Delivery Mold: Delivery to Customer;

7. Product Making;

8. After Sale Information Communication.

OUR ADVANTAGE

6. Inhouse CNC machining center, Sodick slow-feeding wire-cut, Sodick mirror EDM, CMM etc

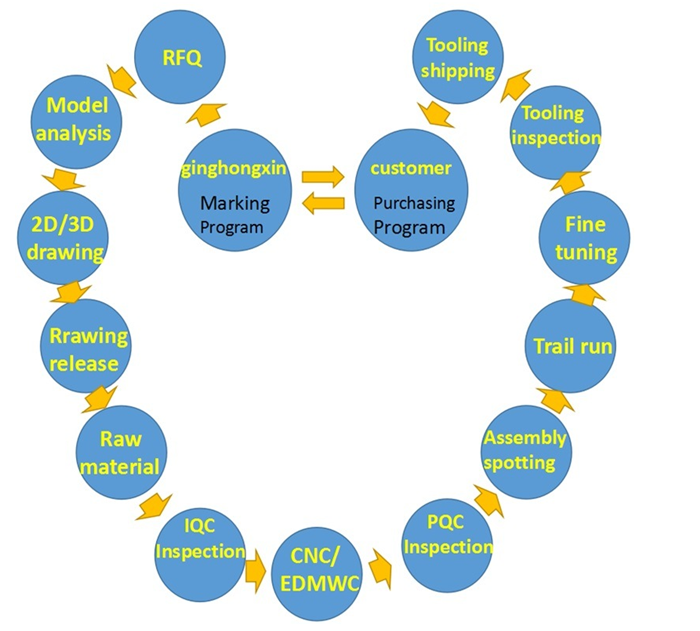

Project process managment

FAQ

Q: What should I provide for price enquiry?

A: The 3d drawing (in STP/ STEP/ IGS/ X_T/ SLD format) with

information about material, quantity, surface treatment, tolerance,

and requires.

Q: If I don't have drawing, how can I get prototype?

A: If you don't have any drawing, you can send us your samples,

we'll scan it and make the drawing first, then make prototype for

you.

Q: What is your MOQ ( minimum order quantity)?

A: The MOQ is 1,000pcs for injetcion molding, you are welcome to

send us trial order to test our quality and services.

Q: What is your payment term?

A: CIF, EXW or FOB Shenzhen, paid by T/T.

Q: Which material will your factory use to make a mold?

A. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q: Are you trading company or manufacturer?

A: We are a tool manufacturer specialized in customized injection

molds, mold components, plastic products for foreign markets.

Q: I have a sample but don’t have drawing, what can I do?

A: Please send us some photos of the sample. And you can send us a

sample and tell us your idea ,we will help to finish the 3D drawing

design

Q:Can you produce if I have a drawing?

A: Please send your drawing to our sales representative, then all

the information will be forwarded to our engineer and they will

evaluate it. A detailed proposal will be advised within 24 hours.

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication factory with an experienced engineering team to make custom products according to clients'drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we will not release your design to third party unless with your permission. And we can sign the NDA before you send the drawing.

KYE team is at your service offering professional expertise, flexibility and accuracy in assumed deadlines.We are able to offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement

Welcome your visit and looking for the inquiry from you.

|

|