| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Thick Film Heater |

|---|---|

| Place of Origin: | JiangSu |

| Brand Name: | Hotlong |

| Supply Ability: | 15000 Piece/Pieces per Month |

| Packaging Details: | carton box |

| MOQ: | 50-100 |

| Price: | consultative |

| Certification: | ISO9001,UL,CE |

| Delivery Time: | 7-10 |

| Applicable Industries: | Machinery Repair Shops, Manufacturing Plant |

| After Warranty Service: | Online support |

| Local Service Location: | United States, Germany, Japan, South Korea |

| Showroom Location: | None |

| Condition: | New |

| Type: | polyimide film heater |

| Power Source: | Electric |

| Dimension(L*W*H): | custom made |

| Weight: | according to product |

| Voltage: | custom made |

| Warranty: | 1 YEAR |

| After-sales Service Provided: | Online support, No overseas service provided |

| Key Selling Points: | Sustainable |

| Warranty of core components: | Not Available |

| Core Components: | thick film |

| Machinery Test Report: | Not Available |

| Video outgoing-inspection: | Not Available |

| Material: | polyimide film |

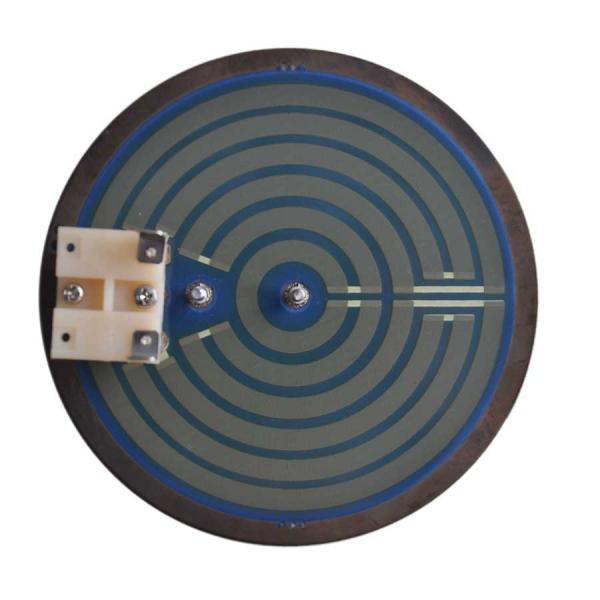

Stainless steel electric kettle heating element flat thick film heater thick film heater

Heater design

The following introductions are to assist customers in designing

their products. Customers are obliged to judge whether their

designs are reliable and safe.

Power density

ESL recommends that the thickness of all 29XXX resistor pastes

after sintering be 10-12 microns to ensure that the power density

is above 60 watts per square centimeter.

Current density

ESL recommends a thickness of 10-12 microns after sintering to

ensure that the current density of the resistance element is 3

amperes per millimeter.

TCR considerations

The material used in the thick film heater has a high TCR, so the

difference between the resistance value at room temperature and

operating temperature must be considered.

| ◊ Heat resistant temp. | |

| continuous use temp. | 200°C(customized) |

| max. temp. | 250°C(customized) |

| ◊ Power characteristics | |

| insulation resistance | 1000MΩ or over DC500V(customized) |

| withstand voltage | 1500V/1min(customized) |

| ◊ Size | |

| max. | customized |

| min. | customized |

| thickness | customized |

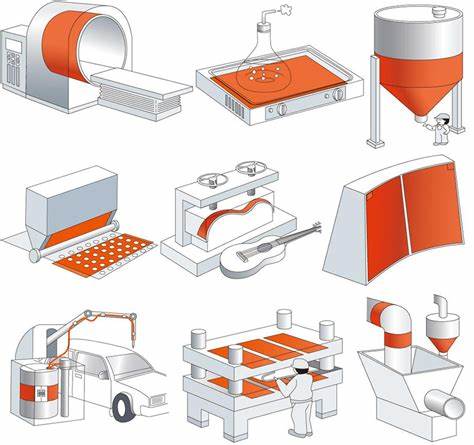

Applications

Thick film products are mainly used in:

1. Heating products with high requirements for heating speed and

efficiency

2. Heating products with relatively small structural volume or

weight requirements

3. Heating products that require low starting voltage

4. Heating products with high power density

5. Heating products needing long service life

6. Heating products requiring controllable temperature heating

field.

7. Heating products with higher energy-saving requirements.

8. Heating products under hard environment (such as long-term high

temperature, high humidity, constant corrosion and vibration).

![]()

![]()

Q: Are you manufacturer or trade company? A:We are manufacturer for more than 20 years. Q: Do you provide OEM or ODM? A:Yes, OEM and ODM are both OK. Q: How does your factory control the product quality? A:We always pay much attention to the quality control from the procurement of raw material to shipment. Q: How do you guarantee the buyers’ after-sell rights and interests? A:All our heating goods enjoy 300USD product liability. Q: How can we get the sample? A:We provide customized sample with a little sample fee and we can return when you place order, so please feel free to contact us! |

|