| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Waterproof Pressure Sensor |

|---|---|

| Place of Origin: | China |

| Brand Name: | OEM |

| Supply Ability: | 20,000 pcs per month |

| Packaging Details: | Stardard Export Packing By carton |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Certification: | CE;ISO |

| Delivery Time: | 5-10days |

| Payment Terms: | L/C, T/T, Western Union |

| type: | pressure sensor |

| usage: | Industrial usage |

| place of origin: | Shaanxi, China(mainland) |

| power supply: | 12-24VDC (10-30VDC) |

| Output: | 12-36VDC/24VDC |

| Setting distance: | 0-1.4mm, 0-2.8mm, 0-5.6mm... |

| Control output: | max.200ma |

| Accuracy: | 0.1%FS; 0.2%FS; 0.5 %FS |

| Media: | gas, air, liquids, weak corrosive |

| Certificate: | ISO9001-2008 |

| Company Info. |

| Beijing Silk Road Enterprise Management Services Co.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Oil Filled Waterproof Pressure Transducer

Introduction

waterproof pressure transducer is an isolated oil - filled pressure sensor core with high performance, low cost and small volume. It uses MEMS Silicon chip. Manufacturing of each sensor is a process with strict aging, screening and testing to ensure the excellent quality and high reliability.

This product has high anti-overload capacity and wide temperature range, it is widely used in automobiles, loading machinery, pumps, air conditioning and other occasions where have high requirements on small size and cost-effective.

Feature

Ø Measuring range: -100kPa…0kPa~10kPa…100MPa

Ø Wide temperature compensation: -10℃~+80℃

Ø Imported chip, Laser trimming

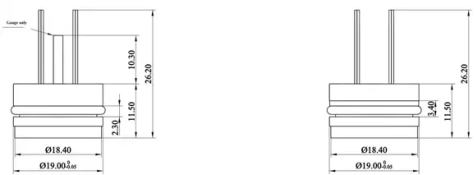

Ø SS 316L φ19mm*11.5mm

Application

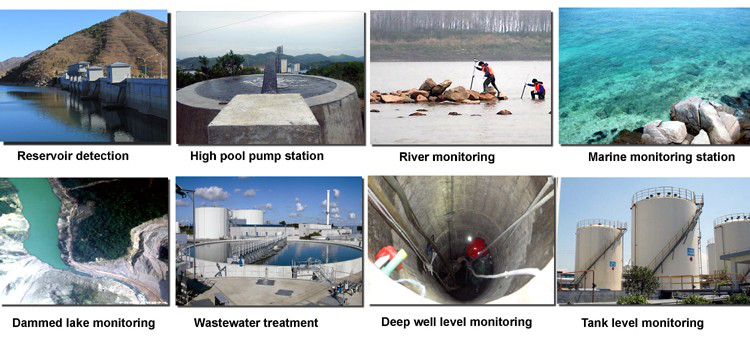

Ø Pressure measurement of automobile engine oil

Ø Engineering machinery, water pumps, equipment

Ø Industrial process control

Ø Urban water supply system

Outline Construction:(Unit: mm)

Specification

Construction Condition | |

Diaphragm material | SS 316L |

Housing material | SS 316L |

Pin Wire | Kovar/100mm silicone rubber wire |

Back pressure tube | SS 316L (gauge and negative pressure only) |

Seal ring | Nitrile rubber |

Electrical Condition | |

Power supply | ≤2.0mA DC |

Impedance input | 3kΩ~6kΩ |

Impedance output | 3kΩ~6kΩ |

Response | (10%~90%):<1ms |

Insulation resistance | 100MΩ,100V DC |

Overpressure | 2 times FS |

Environmental Condition | |

Media applicability | Fluid which has no corrosion on stainless steel and nitrile rubber |

Shock | No change at 10gRMS,(20~2000)Hz |

Impact | 100g,11ms |

Position | Deviate 90° from any direction, zero change≤±0.05%FS |

Basic Condition | |

Environment temperature | (25±1)℃ |

Humidity | (50%±10%)RH |

Atmospheric pressure | (86~106) kPa |

Power supply | (1.5±0.0015)mA DC |

Parameter

Item | Min. | Typ. | Max. | Units |

Linearity | ±0.1 | ±0.2 | %FS,BFSL | |

Repeatability | ±0.05 | ±0.075 | %FS | |

Hysteresis | ±0.05 | ±0.075 | %FS | |

Zero output | ±2.0 | mV DC | ||

FS output | 45 | 130 | mV DC | |

Compensated temp. range | -10~80 | ℃ | ||

Working temp. range | -40~125 | ℃ | ||

Storage temp. range | -55~150 | ℃ | ||

Zero temp. error | ±0.75 | ±0.1 | %FS, @25℃ | |

Full temp. error | ±0.75 | ±0.1 | %FS, @25℃ | |

Long term stability error | ±0.2 | %FS/year | ||

Note:1. The above performance indicators are tested under the benchmark conditions | ||||

2. The temperature range for temperature drift test is the compensation temperature range | ||||

|