| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | TDI Based Polyurethane |

|---|---|

| Brand Name: | EXCEEDCHEM |

| Model Number: | TDI-100/Polyester Polyurethane Prepolymer Shore A90 |

| Certification: | ISO9001:2008 |

| Place of Origin: | China |

| MOQ: | 1mt |

| Price: | FOB Qingdao usd3.0/kg |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 3000mt/month |

| Delivery Time: | 5-8 work days |

| Packaging Details: | 20kg/drum; 200kg/drum |

| NCO%: | 4.30-4.50 |

| MOCA%: | 12.5 |

| Hardness: | Shore A90 |

| Base: | TDI-100/ polyester based |

| Packing: | 20kg/drum; 200kg/drum |

| Shelf life: | 6months |

| Company Info. |

| Qingdao Exceed Fine Chemicals Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

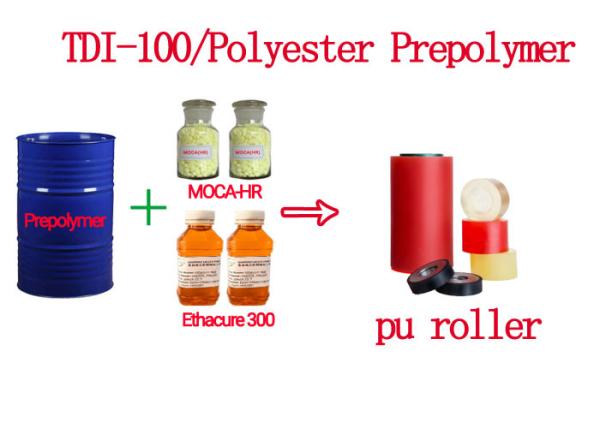

TDI-100/Polyester Polyurethane Prepolymer Shore A90

1. Description

This is a TDI-100 based Polyester polyurethane prepolymer.

2. Characteristics

3. Applications

4. Typical properties

| Type | Appearance | Viscosity(mPa.s/85℃) | NCO% | Packing(kg/drum) |

| Solid | 1300-1500 | 4.30-4.50 | 20/200 |

5. Operating Procedure

First, the prepolymer should be preheated in 80-85℃. Second, after vacumming, the prepolymer is to be mixed with melting MOCA evenly. Third, with degassing, casting into mould, and vulcanization,and then demould. Lastly, the finished product should be post vulcanized.

6. Reaction parameters

| Item | MOCA (%) | Gel time(min) | Mixing temperature(℃) | Post vulcanization(h) |

| Specification | 12.5 | 8-9 | 80/120 | 10 |

7. Finished products properties

| Item | Hardness(Shore A) | Tensile strength(MPa) | Tear strength(KN/m) | Rebounding(%) |

| Physical properties | 90 | 48-50 | 100-105 | 36 |

| Temperature/℃ | Time |

| 60 | 7 days |

| 70 | 3 days |

| 80 | 36 hours |

| 90 | 12 hours |

| 100 | 8 hours |

|