Introduction and function

This machine applies the transmission principle. It uses the slot

wheel dividing system to drive the turntable to do intermittent

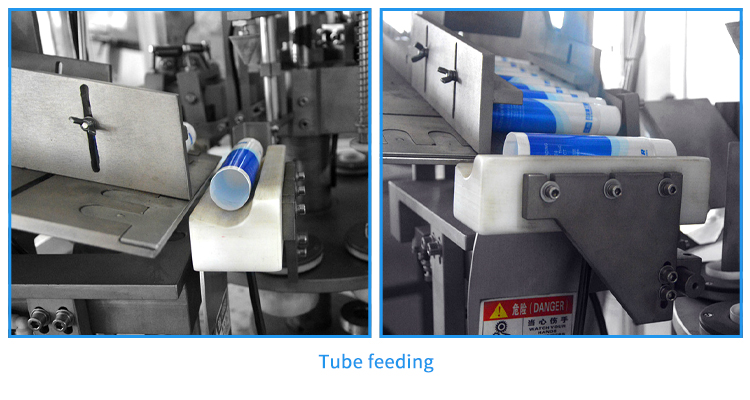

movement. The machine has 8 sits. Expect manually putting the tubes

on the machine, it can automatically fill the material into the

tubes, heat both inside and outside of the tubes, seal the tubes,

press the codes, and cut the tails and exit the finished tubes.

Filling measurement is accurate. Heating time is stable and

adjustable. Sealed tail looks pretty and neat and the trimming is

very even. This machine has stable performance and work without any

noise and pollution.

The part which is contact with the filling material is made of

high-quality stainless steels. The parts which need to clean are

made of quick-change device that is removable and convenient for

washing.

If some materials need heating insulation, the heating thermostat

device can be added outside of the feeding barrel.

Main functions:

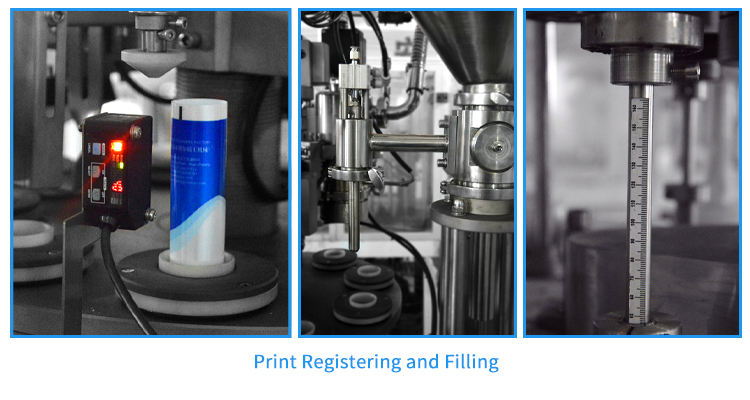

1. automatic tube orientation

2. automatic heating

3. automatic sealing and pressing the batch, dates

4. automatic cutting the tail

5. automatic exiting

Application range:

It can fill and seal the plastic tubes and plastic-aluminum

laminated tubes. It is widely used in the cosmetic, medicine,

adhesive and shoe polish, food industries.

Main Features

1) Automatic tube loader-Automatic print registration-Tube

orientation checking-Fiiling-Inner Heating-Sealing and Dater

Printing-Cutting-Discharge

2) Adopting advanced world famous brand Mitshubish, Schneider,

Omron, Leister erccomponents in pneumatic parts ,electric parts and

operation parts.

3) High Standard quality control and safety protection.

4) Mechanical transmission device provide stable and easy

operation.

5) Could match cartoning machine and film packing machine together.