| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Laboratory Spray Dryer |

|---|---|

| Brand Name: | OEM |

| Certification: | CE;ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 20-30days |

| Packaging Details: | Standard export Carton |

| Payment Terms: | L/C, T/T |

| Item Name: | LPG-5 laboratory use electric-heating centrifugal spray drying equipmeny in small capacity |

| Model Type: | LPG series centrifugal spray dryer |

| Condition: | 100% new |

| Steel Material: | mainly drying material contact parts are stainless steel |

| Color: | carbon spray paint as customers' prefer |

| Atomizer Speed: | 8000-25000 rpm, adjustable |

| Heating Source: | water, heat-transfer oil, etc. |

| Electric Power: | 380V, 50Hz, 3 Phase |

| Company Info. |

| JIANGSU GUOJIN DRYING TECHNOLOGY CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Electric Heating LPG-5 Centrifuga Laboratory Spray Dryer

Brief Introduction of Spray Dryer:

| Item Name | LPG-5 laboratory use electric-heating centrifugal spray drying equipmeny in small capacity |

| Common Size | The max size we supply before is LPG-7000, the spraying desc is 7m. |

| Rotarion Speed | the rotary speed can been adjustable from 8000 rpm to 25000 rpm. |

| Dried Powder Collecting | more than 95% |

| Kinds of Spray Dryer | 1. centrifugal spray 2. pressure spray 3. Traditional Chinese medicine spray 4. Air spray |

Suitable materials of centrifugal spray dryer:

Chemical industry: sodium fluoride (potassium, basic dye pigment, dye intermediate, compound fertilizer, formaldehyde-silicic acid, catalyst, sulfuric acid, amino acid, silica, etc.

Plastic resin: ABN ABS emulsion, urethral resin, phenolic resin, polyvinyl chloride, polyvinyl chloride, polyvinyl chloride, polyurethane-formaldehyde resin.

Food industry: fat-rich milk powder, skeleton milk, cocoa milk powder, milk powder, blood hunting powder, egg white (yolk), etc.

Foods and plants: oats, chicken juice, coffee, instant tea, seasoned spices, protein, soy, peanut protein, hydrolysate, etc.

Sugar: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

Ceramics: alumina, ceramic tile, Magnesium Oxide, talc and so on.

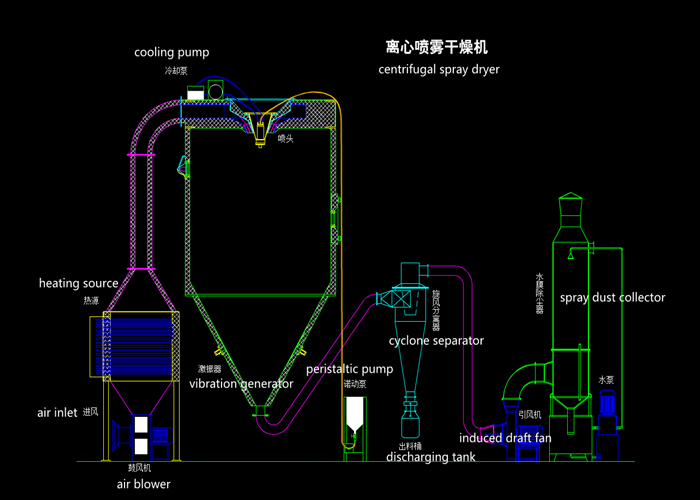

How is the centrifugal spray dryer work ?

If indeed, you can also contact us and ask for an animation demo version.

What is the most suitable heating source supply ?

Notes: It can been settled by customers yourselves.

What is the different characteristic of centrifugal spray dryer from others ?

Why choose the centrifugal spray dryer to drying ?

How many pieces of selection informations we need ?

Or you can choose to fill in the selection form as following:

Pictures of Centrifugal Spray Dryer:

|