High Speed Disposable Pollution Mask Machine Size 6600 × 3600 ×

2000mm

Brief Description of Equipment

Equipment overview

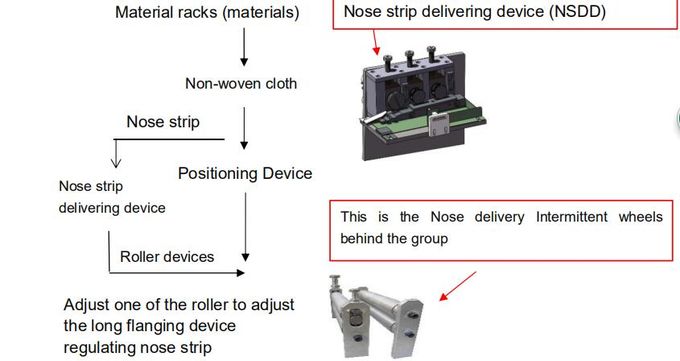

This machine is mainly used for automatic forming of flat face

mask: the whole roll cloth is rolled and driven by roller, the

cloth is formed by automatic folding and wrapping; the whole roll

of nose strip is pulled and unwinding, fixed length cut and

imported into the wrapping cloth

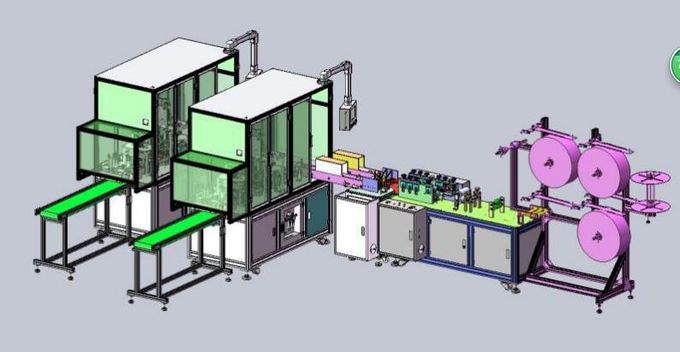

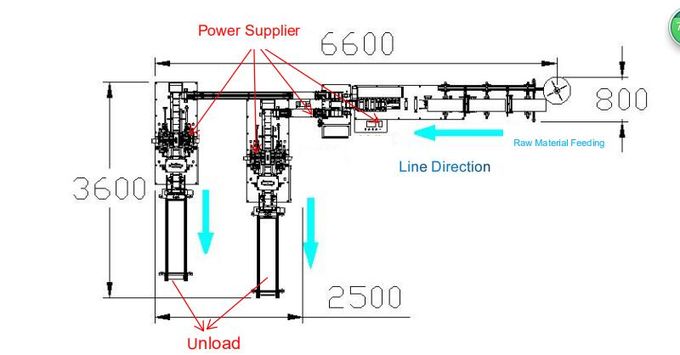

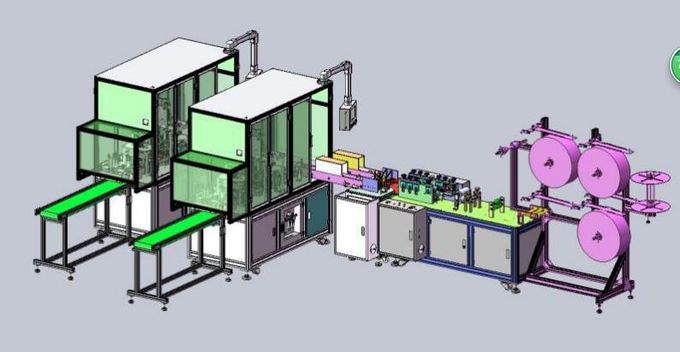

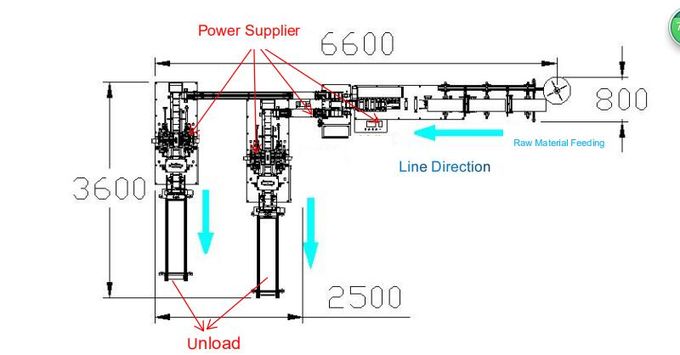

Schematic diagram of equipment

(This drawing is for reference only and the equipment is in kind)

Equipment installation and configuration requirements

(1) Size of equipment :6600 mm (L)×3600 mm (W)×2000(H);

(2) Appearance color: sheet metal RAL7035( standard color), without

special description according to this standard;

(3) Weight of equipment :≤5000 kg, ground load ≤500 KG/m2;

(4) Working power supply: equipment single phase 220 V,50HZ, rated

power about 12kW;

(5) compressed air :0.5~0.7 MPa, use flow rate approximately 300

L/min;

(6) Use environment: temperature 10~35℃, humidity 5-35% HR, no

flammability, corrosive gas, no dust (cleanliness not less than

100,000 grade).

(7) Operator :1 person

Main Components of Equipment

| Ser.No. | NameofPart | QTY | Remark |

| 1 | Filterwatercloth/filtercotton/absorbentlayerunwindingmechanism | 3 sets | |

| 2 | Nosebeamunwindingmechanism | 1 set | |

| 3 | Straighteningofbridge | 1 set | Width3mm |

| 4 | Nosebeamdrivingandcuttingmechanism | 1 set | Width3mm |

| 5 | Fabrichemmingmechanism | 1 set | |

| 6 | Edgesealingmechanismforrollingwelding | 1 set | |

| 7 | Fabricdrivemechanism | 1 set | |

| 8 | Rollingsealingmechanism | 1 set | |

| 9 | Transferpipeline | 2 strip | |

| 10 | Diversionmechanism | 2 sets | |

| 11 | EarBeltWeldingMachine | 2 sets | |

| 12 | Dischargeassembly | 2 strip | |

| 15 | Operatingsystem | 1 set | |

| 16 | Operatingpanel | 1 set | |

Materials and Product Quality for Equipment

Applicable incoming material specifications

| Projects | Gramweight | Width(mm) | Coildiameter(mm) | Innerdiameter(mm) | Weight |

| Non-wovenfabric(veneer) | 20 | 190 | Φ600 | Φ76.2 | Max15kg |

Non-wovenfabric(outermostlayer) Blueandothercustomerdefinitions | 25 | 175 | Φ600 | Φ76.2 | Max15kg |

| Fusespray | 25 | 170-172 | Φ600 | Φ76.2 | Max15kg |

| Bridge | | About 3 | Φ450 | Φ150-Φ330 | Max25kg |

| Earband | | Φ3flatrubberband | Bagpacking | |

Production specifications

Standard:175*95mm

Technical Parameters of Equipment

1. production efficiency :70~120 tablets per minute (the total

output of two earband machines will be adjusted according to the

actual production situation).

2. Qualified rate of equipment production :99% (when incoming

materials do not meet the requirements, except for improper

operation by employees).

3. Equipment failure rate: 2%(refers to the failure caused by the

equipment itself)

Installation,Commissioning and Training

1. Open the control box and turn the power switch to the ON

position, power indicator light on, press the start button, adjust

the speed regulator to the appropriate speed and turn the adjust

switch to the OFF position( to facilitate the following material).

2. Place the material separately on each shaft of the rack as shown

in the part name diagram.

3. Wear material (specific commissioning with reference to working

principle and operational precautions)