| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Spacer Bending Machine |

|---|---|

| Brand Name: | LIJIANG |

| Model Number: | LJZW2020 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5sets/month |

| Delivery Time: | Within 15 days |

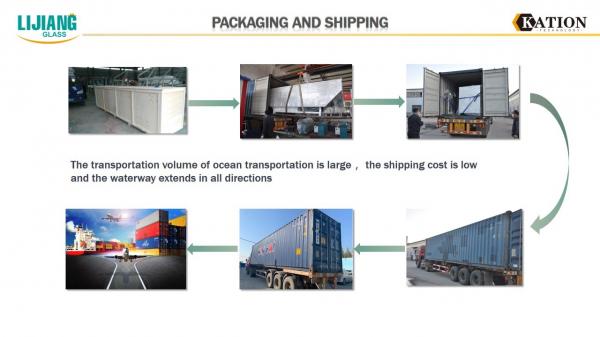

| Packaging Details: | Container |

| Name: | Autimatic spacer bending machine |

| Max.bending size: | 2000mm*2000mm |

| Min.bending size: | 250mm*200mm |

| Aluminum spacer width: | 6A-27A |

| Dimensional error: | ≤±0.5mm |

| Angle error: | ≤±1 |

| Air supply: | ≥0.65MPa |

| Total power: | Ac220/380V 50Hz 2.5KW |

| Dimension: | 10500mm*2200mm*2600mm |

Autimatic spacer bending machine(LJZW2020)

Automatic spacer bending machine is a special equipment for manufacturing insulating glass aluminum frame instead of insulating glass. The equipment can form one aluminum belt at a time to make various convex polygonal aluminum frames, so as to reinforce and manufacture the aluminum frames. The sealing effect of insulating glass is better.

The automatic bending machine continuously bends the aluminum frame in the hollow glass. The bending of the aluminum frame can improve the sealing performance of the insulating glass, and the appearance is better.

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Heavy-duty connectors provide convenience and safety for installation and commissioning

SB input function, directly read excel format files, etc. (optional)

Connect to ERP system (optional)

It can bend aluminum gasket, Technoform, Alupro, Thermix, temperature spacer (Swisspacer) and stainless steel (optional), etc.

We have a special soft system that can avoid the distance of 120mm to reduce waste. For example, if the length of the gusset is 60mm, the gusset will appear when the program calculates the right angle. When you start to bend the rectangular frame, you first need to transport 120mm, then cut 120mm, and then step on the pedal to bend the frame, which will waste 120mm.

|