| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic Twin Screw Extruder |

|---|---|

| Brand Name: | ADVS |

| Model Number: | HPL62 |

| Certification: | ISO9001 |

| Place of Origin: | SiChuan, China |

| MOQ: | 1 |

| Price: | USD 34000-200000 |

| Payment Terms: | T/T |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 90 days after payment of deposit |

| Packaging Details: | Wooden base plate, damp proof plastic lining |

| Screw design: | double screw |

| Application: | GF reinforced with flame redardant additives |

| Plastic processed: | PA6,PA66,PBT |

| Warranty: | extruder 1 year, gearbox 3 years |

| Inverter: | ABB, Simenes |

| Screw diameter: | 61.5mm |

| Company Info. |

| Sichuan Advance technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Twin screw extruder line for 30% glass fiber reinforced with flame retardant PA66/PA6

Product Description

The extruder line is special for producing 30% glass fiber reinforced with flame retardant PA66/PA6/PBT .For the high torque, it has higher output and lower temperature than other low torque extruders.And uniform screw clearance enables uniform despersion, with retaining fibre length.

Technical data

| Screw diameter | 61.5mm |

| L/D | 44:1 |

| Screw speed | 60~600rpm |

| Drive motor power | 200Kw |

| Torque per shaft | 1592N.m |

| T/A3(Nm/cm3) | 12 |

| D/d | 1.56 |

| Output | 500-800kg/h |

| Screw element | Corrosion resistant and wear resistant |

| Liner of barrel | Corrosion resistant and wear resistant |

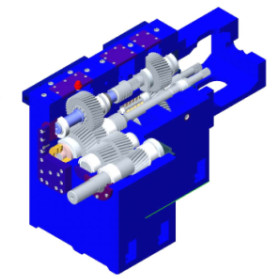

| Gearbox | Bilateral symmetry gear drive system realize high torque output |

| Machine frame | Whole steel plate welded basic frame |

Our advantages

1. High output

The output is 1-2 times larger than the same size extruder from other lower torque twin screw extruders.

The biggest extruder can output up to 12T/h per set.

2. Energy-saving

For the same output , our small size extruder can replace the big size of other extruder, such as our HPL51 has more output than other 65 extruder , smaller extruder, less energy consumption,less material consumption, smaller production areas.

And we use heat rod instead of cast copper heater, which can save 15%-20% energy.

3. Advanced design

High torque: carrying capacity factor of gearbox up to 15Nm/cm3;

High speed: max. 1800rpm/m;

4. Long service life

bearings on output shaft 2 without load, which greatly extended the service life of the bearings on the weak axis , gearbox life can reach 72000 hours (10 years);

5. Custom made design

Wide D/d choice:1.33~2.0;

Custom made clearance: minimum clearance can be 0.15mm;

Parts and advantages

| Transmission gearbox |  | The most advanced structure: bilateral symmetry gear drive system; it’s the same with the gearbox of German Flanders, Austria EssenBas.Now, the first-line extruder manufacturers in the world, such as Corperion,Berstorff, Leistritz, Toshiba, JSW are using the transmission structure; servcie life of the gearbox≥72000hrs. |

| Screw element |  | Various kinds of function elements, mixing and dispersing elements developed by ourselves can provie flexible production for kinds of materials and production process. Optional material: W6Cr5Mo4V2, Ni-based alloy, HIP alloy,Co-based alloy. |

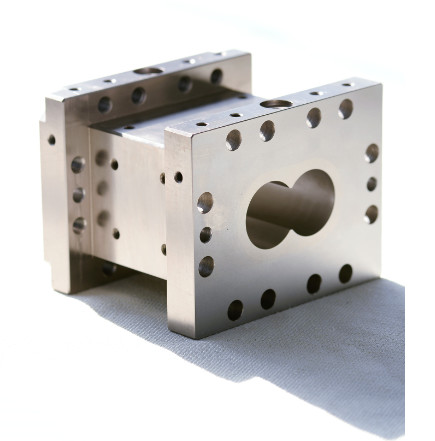

| Barrel |  | Barrels are equipped with integrated wear-resistant alloy steel liner, which has the same composition and wearing feacture with W&P .Our mirror polishing seamless barrels, surface finish Ra0.2, verticality between barrels inner hole≤0.015mm;linearity of ten assembled barrels≤0.05mm; Optional material: W6Cr5Mo4V2, Nitriding steel, Tool steel, Ni-based alloy, HIP alloy,Co-based alloy. |

| Torque limiter |  | Steel ball type safety clutch + torque limiter Made in Germany have the characteristics of accurate torque protection, high repeatability and quick reset. |

| Side feeder |  | Our CWJ series side feeder can be used to feed powders and short fibres, which can improve the output and reduce abrasion of scew and barrels. And segmented screws available. Barell with cooling function is available. |

About us

We are dedicate to develop, design, and manufacture co-rotation, counter-rotation parallel twin-screw extruder production line.Our extruders have the advantages of “high torque, high efficiency, low energy-consumption, high price/performance ratio, long service life ” (designed service life of gearbox as long as 72000 hrs). We keep the same step with the most advanced extruder manufaturers in the world.

We can supply :Twin screw extruder production line;

High torque gearbox;Automatic long fiber reinforced thermoplastic composites (LFT - D) production line;Counter-rotation parallel twin screw extruder;Differential concentration mixer;

Repairing and machining large parts; Design, machine all of screw elements on Japan and Germany extruders.

|