| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Precision Casting |

|---|---|

| Brand Name: | ABlinox |

| Model Number: | ABL-V16 |

| Place of Origin: | China |

| MOQ: | 100PCS |

| Price: | Negotiation |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 200T/month |

| Delivery Time: | 33days |

| Packaging Details: | carton packing |

| Certification: | ISO9001:2015,CE |

| Product name: | Valve |

| Material: | Stainless steel 304 |

| Usage for: | fluid |

| weight: | 6.2kg |

| standrad: | GB,ISO, AISI, DIN, etc |

| Certificate: | ISO 2010 |

| Surface Roughness: | Ra 0.4um-13.83um |

| Quality: | good quality |

| Service: | OEM |

| Sample day: | 25days |

China Valve Casting Factory Lose Wax Casting sand blast finish stainless steel Butterfly Valve Parts For Fluid Pump

| Place of Origin: | Guangdong,China | Port: | Guangzhou |

| Material: | Stainless Steel 304,201,202,CF8,,WCB,1.4408,1.4308, | Size: | According to drawing |

| Technology: | Precision Investment Casting | Process: | CNC Machining,Surface Treatment |

| Surface Treatment : | Customized | Casting Tolerance: | CT4~CT6 |

| Brand Name: | ABLinox or OEM | Packing: | As client’s requirements |

| Standard: | GB,DIN,AISI,ASTM,BS,JIS | Certification: | ISO9001:2015 |

| Quality Control: | 100% inspection | Lead Time: | 30~35 Days |

| Application: | Industrial Parts valve and pumps | ||

Stainless steel's biggest advantage is its excellent corrosion resistance. Unlike other materials, stainless steel investment castings have a built-in chromium oxide layer that provides exceptional anti-corrosive properties.

Applications

* Computing equipment

* General machinery

* Valves

* Pumps and pipe fittings

* Hardware tools

* Sanitary fittings

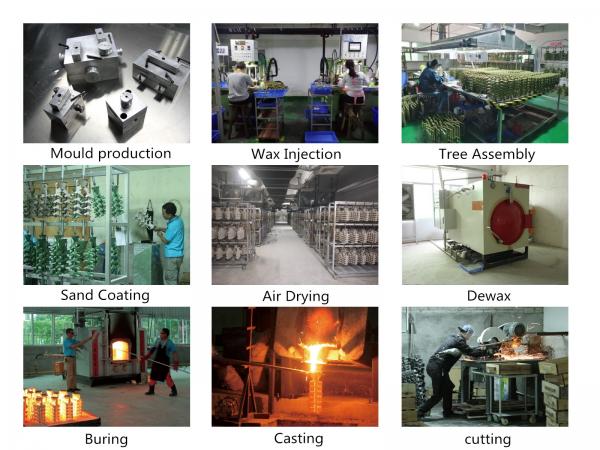

Production Process

Mold Producing→Wax Injection→Cluster Assembly(Tree)→Sand Coating→Dewaxing→Burning→Chemical Analysis→Casting→Shell Removal→Part Removal→Finishing→Visual Inspection→Machining→Surface Treatment→Assembling→QC→Packing

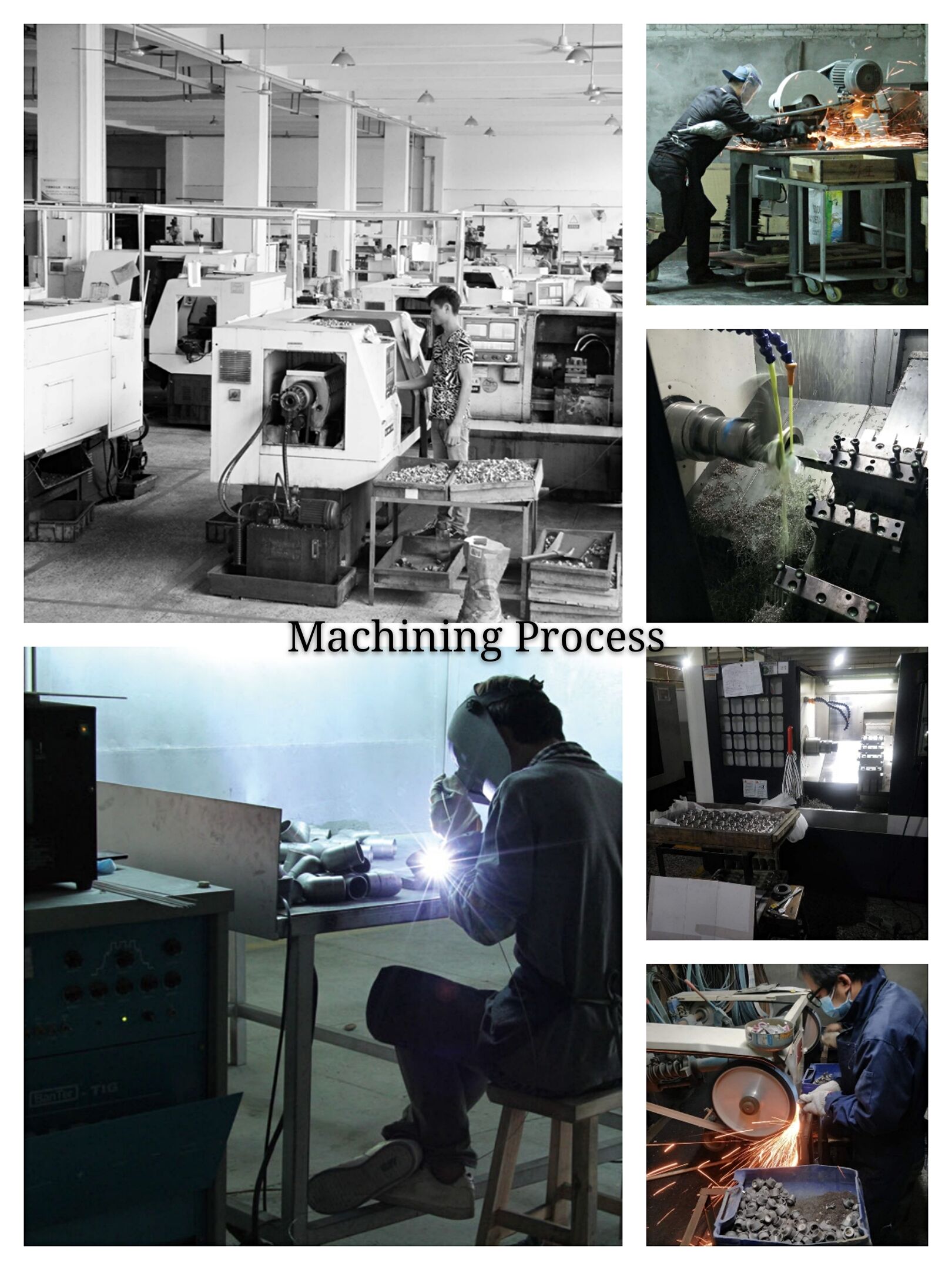

Equipments

We specialize in turning, drilling, tapping, and a variety of other machining capabilities to offer a complete product.

With these in-house turning capabilities, we also can quote your bar stock requirements, which complementsour investment casting line.

Our Service

1. Sample is available.

2. OEM/ODM products are available.

3. Professional and reliable service through the whole procedure

4. Superior quality compared to other suppliers .

5. The raw material will be tested by German Spectrograph.

6. The 50,000 SQM factory and the newly founded Casting Workshop

guarantees our capacity.

7. The advanced equipments and qualified engineers ensures the

quality of products.

8. The professional sale team can provide you our best services.

Feedback Time: within 12 hours

Quotation Time: within 48 hours

Mold Making: 7-15 days

Sample Making: 5-7 days

Delivery Time: 20 to 35 days

Quality Control

Quality inspection at each stage,

1. Incoming material inspection 2. Inspection of work-in-progress

3. Finished product inspection 4. Random warehouse inspection

|