Product Description

Easy operation scrap tire recycling line

Introduction

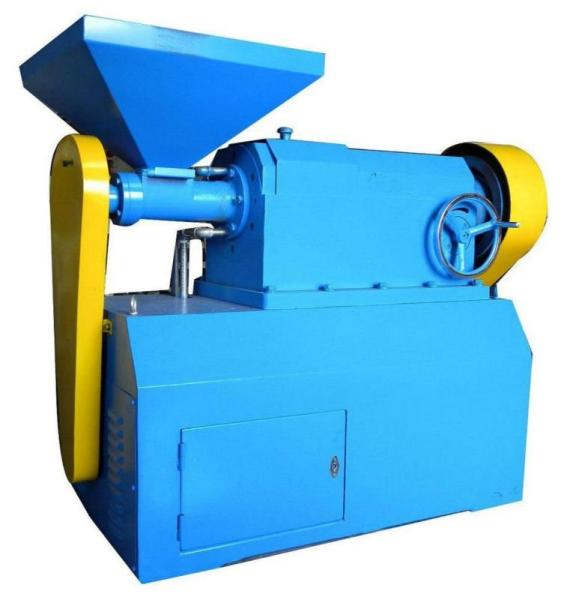

Developed by adopting advanced domestic and overseas technology, it

is widely used in natural, synthetic rubber and plastic powder

production. It is mainly composed of miller, collector, draught

fan, cyclone and control cabinet, etc.

Structure and Principle

The machine is composed of one or multiple millers, collector and

control system. The miller consists of frame, motor, stepless

feeding motor, feeding device, fixed and rotary discs, the basic

principle is to mill and grind rubber into powder by the relative

movement of fixed and rotary discs. Wind and water cooling system

can ensure the milling output quality. Feeding device use stepless

motor, the feeding speed can be changed according to production

requirements.

With such features as low noise, high output, easy operation and

maintenance, no pollution and even milling size, etc.

| Model | 28-1 | 28-2 | 28-3 | 28-4 | 28-5 | 28-6 | 28-8 |

| Capacity(Kg/H) | 60~200 | 120~400 | 180~600 | 240~800 | 300~1000 | 360~1200 | 480~1600 |

| Feeding size(mesh) | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 | 5~20 |

| Output size(mesh) | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 |

| Motor power(Kw) | 30+0.75+3 | 30×2+0.75×2+4 | 30×3+0.75×3+5.5 | 30×4+0.75×4+7.5 | 30×5+0.75×5+11 | 30×6+0.75×6+15 | 30×8+0.75×8+18.5 |

| Milling temperature(℃) | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| Weight(T) | 1.8 | 3 | 4.5 | 6.2 | 8 | 10 | 13.8 |

| Dimension(m) | 2.5×2.5×2.8 | 4×2.5×2.8 | 5.5×2.5×2.8 | 7×2.5×3.2 | 8.5×2.5×3.2 | 10×2.5×3.8 | 13×2.5×3.8

|