| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Non Woven Face Mask Making Machine |

|---|---|

| Place of Origin: | CHINA |

| Brand Name: | OEM |

| Certification: | CE/ISO9001 |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Packaging Details: | Wooden Case |

| Delivery Time: | in - stock |

| Payment Terms: | Negotiable |

| Name: | Non Woven Mask Making Equipment |

| Feature: | High Performance |

| Application: | Producing Non Woven Face Mask |

| Power Supply: | 220V/50HZ |

| Control mode: | PLC Display and touch Screen |

| type: | Disposable Face Mask Machine |

| Supply Ability: | 4 Set Per Month |

| Model Number: | OEM |

High Speed Disposable Face Mask Machine , Non Woven Mask Making Equipment

Description

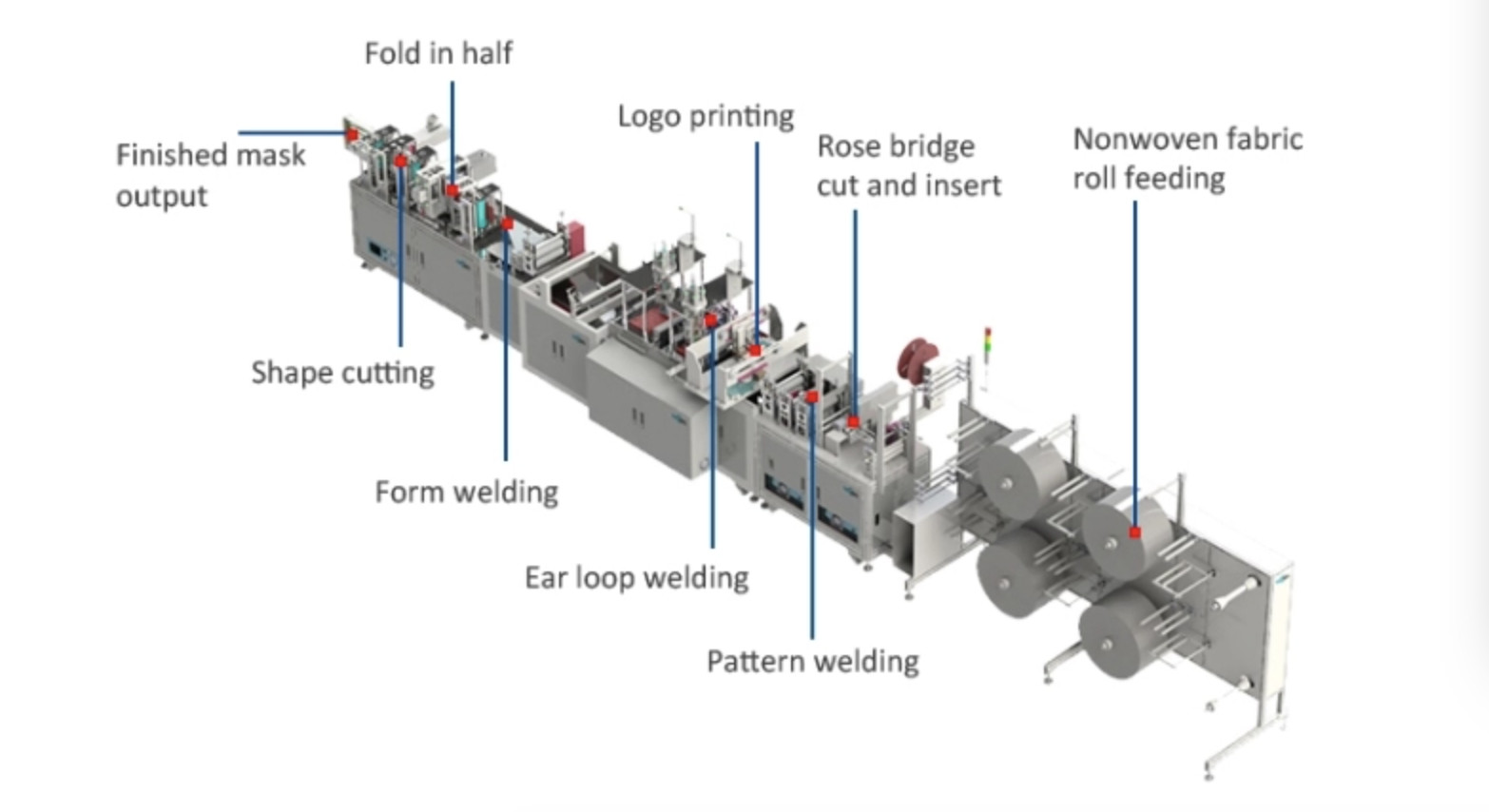

This mask machine is used for the automated production of mult layer material plane mask body, you can use a Layer 4 (according to customer request custom multi layer) PP spunbond non-woven activated carbon filter material, in the case of replacement of mold production mechanism gauze masks and masks of different sizes.

Introduce :

1. Adopting aluminum alloy rack which is more light and solider

2. High stability

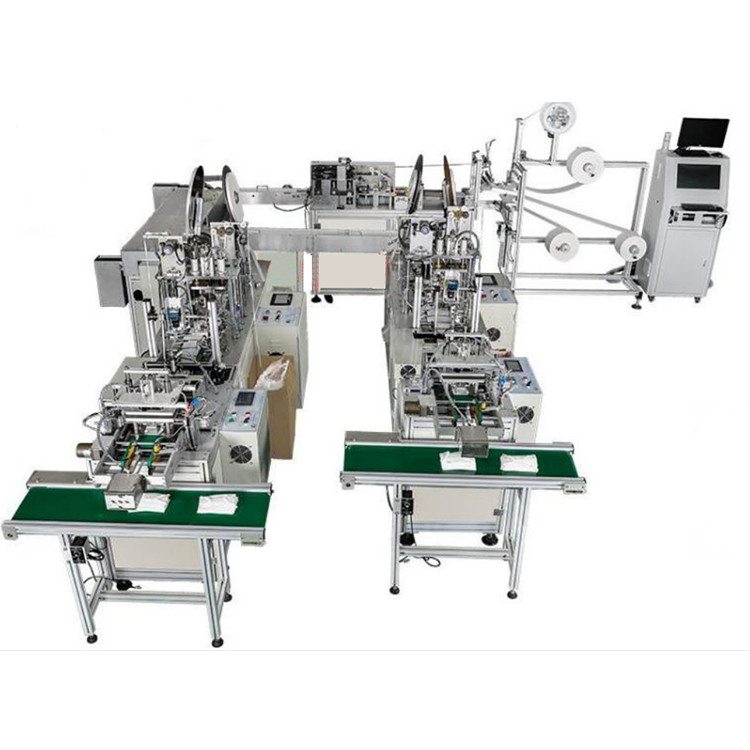

3. Two output line , high capacity

4. Fully Automatically , make outside earloop welding togther with mask producing process which can save labor , once non woven raw material in unwinding part use up , the machine can automatically stop .

Technical parameters

| Speed | 60-70 pcs/min |

| Voltage | 220V 60Hz |

| Machine dimension | 4500*3000*1800 mm |

| Mask Size | 17.5*9.5 cm ( that is standard size , we can also specially customize for your different mask size) |

| Power | 8 KW |

Features

① The whole line has the characteristics of high automation and

high production efficiency;

② The whole machine is made of aluminum alloy structure, beautiful,

solid and rust free;

③ Computer PLC control, servo drive, high precision, good

stability;

④ Automatic tension control of raw materials to ensure the tension

balance of raw materials;

⑤ Multi point photoelectric (optical fiber) detection feeding

system, automatic alarm in case of abnormality, to avoid loss

caused by mistake;

⑥ The folding forming system can effectively reduce product

deformation;

⑦ The full-automatic production line can be used with the automatic

packaging line to realize the integrated unmanned operation.The

semi-automatic slicer and the ear belt spot welding machine can

also quickly achieve the production efficiency, more stable and

reliable, and the cost input is small.

Our Advantages

1. Certified company with CE certificates.

2. Various production line, covering different kinds of professional machinery to produce ultrasonic related machine.

3. Advanced technical support and strict quality management system..High-efficiency and timely service by E-mail, Skype, WhatsApp, etc. and 24-hours telephone service.

4. Having many experience in this field, our machine are in great demand at home and abroad. We have exported the machine more than 50 countries.

FAQ

1. Q: Can you provide overseas services?

A: Yes, we can.

2. Q: How to use the machine?

A: Before sending the packaging machine to you, we will install it and test it, and then pack the whole device in a wooden box, so you do n’t need to install it again,

3. Q: Test packaging before shipment?

A: we will surely 100% of the experimental test machine will be normal without problems.

4. Q: What is the warranty period?

A: One year warranty for the whole machine.

5. Q: What is the payment term?

A: Accept L / C or TT.

6. Q: What is the delivery time?

A: 15-20 days after receiving the deposit. Contact: 7 * 24 hours online service If you need to pack other materials / products or have any questions about the packaging machine, please feel free to email me or call us.

|