| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminium Profile System |

|---|---|

| Brand Name: | HT |

| Certification: | CA ,CE ,ISO14001:2004, ISO9001:2000 |

| Place of Origin: | China |

| MOQ: | 1 ton |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 100 000ton each month |

| Delivery Time: | 20days |

| Packaging Details: | Ep paper ,kraft ,pallet |

| product name: | Industrial Aluminium Profile |

| Alloy: | 6063,6061 |

| Material: | Aluminum |

| Suface Treatment: | Mill Finished,Anodized Powder coated,Drawbench,Steel polished |

| Deep process: | Milling, Drilling, Cutting |

| Temper: | T5, T6 |

| Company Info. |

| Hentec Industry Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

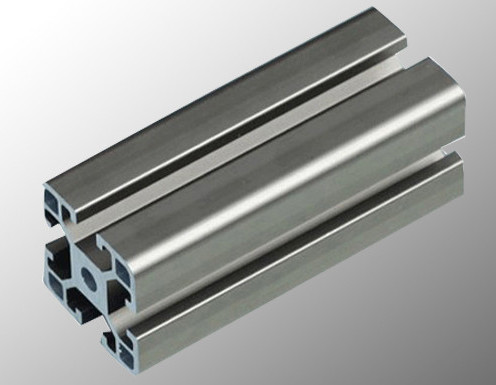

Anodized Industrial Aluminum Extrusion Profiles For Assembly Workshop

We have Germany imported machines and professional engineers.In this case,we can do high technics customized aluminium alloy extrusion and profile as per your drawings or samples.

Product Specification

| Surface Finish: | Mill finish | Anodizing | Powder Coating | Wood Grain | Electrophoresis | Polished | Brushed |

| Color: | Anodizing: | Silver, bronze, champagne, titanium, nickel, golden yellow, etc. | |||||

| Anodizing thickness is up to 25um. | |||||||

| Powder Coating: | White, black, bronze, grey, green, etc . | ||||||

| Powder coating thickness is more than 60um. | |||||||

| Wood Grain: | 1. Italian MENPHIS transfer printing paper. | ||||||

| 2. AKZO NOBEL INTERPON D1010(10 years warranty): Australia ceder, Bush cherry, Chest nut, Jarrah I, Jarrah II, Western red ceder, etc. | |||||||

| 3. AKZO NOBEL INTERPON D34(5 years warranty | |||||||

| Electrophoresis: | Silver, nickel, golden yellow, black, champagne, etc | ||||||

| Polishing | Silver, nickel, golden yellow, black, etc | ||||||

| Brushing: | Silver, nickel, golden yellow, black, bronze, etc | ||||||

| Machining: | Cutting, punching, drilling, bending, weld, mill, CNC, etc. | ||||||

| TABLE OF CHEMICAL COMPOSITION OF ALUMINUM ALLOY | |||||||||

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Al |

6063 | 0.2-0.6 | 0.45-0.9 | < 0.35 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | < 0.1 | Surplus |

6061 | 0.4-0.8 | 0.8-1.2 | < 0.7 | 0.15-0.4 | < 0.15 | < 0.25 | 0.04-0.35 | < 0.15 | Surplus |

| 6005 | 0.5-0.9 | 0.4-0.7 | 0.35 | 0.3 | 0.50 | 0.2 | 0.3 | 0.1 | Surplus |

6082 | 0.7-1.3 | 0.6-1.2 | 0.5 | ≤0.1 | 0.4-1.0 | ≤0.2 | ≤0.25 | < 0.1 | Surplus |

ADODIZINMG QUALITY | ||||

Grade | corrosion resistance | abrasive resistance | ||

CASS test | alkaline dropping test | sandtrial Abrasion coefficient f,g/um | ||

hours | grade | |||

AA10 | 16 | ≥ 9 | ≥ 50 | ≥ 300 |

AA15 | 32 | ≥ 9 | ≥ 75 | ≥ 300 |

AA20 | 56 | ≥ 9 | ≥ 100 | ≥ 300 |

AA25 | 72 | ≥ 9 | ≥ 125 | ≥ 300 |

Description:

1. Material: 6063,6061,6060,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis,

wooden transfer or pvdf/carbon-flouride coated, polishing,

brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue,grey,

champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling,

bending, welding, CNC etc.

6. Various in styles and sizes:

A) Aluminum alloy bars: 6000 series, normal material such as

6063,6005,6061,6060, special materials such as 6082 etc.

B) Aluminum profiles:

---General aluminum profiles (various shapes of pipes/tubes,

angles, T or U shapes etc.)

--- Industrial aluminum profiles ( TV frames, Rim for bicycles and

motorcycles, Heat sink profiles, Furniture, Ladder, Guide Rail,

Leisure materials, Shower Room, Solar Module Frame, Motor Shell,

Pipeline Integration etc.)

--- Construction aluminum profiles

7. Certification: ISO9001,SGS,ROHS,TUV

8. Strong technical development ability, can provide high intensity

and high ductility aluminum profiles, to meet customers' different

requirements.

9. OEM service available, customized design available

Applications:

Industry Aluminum profile used in cars, trains machinery ,electronics, medical and other industrial filed . In terms of hardware, machinery, electromechanical parts, solar PV products, aluminum frames are adopt as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Specifications:

1. Primary Technical Data

1)Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.15 | Rest |

6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.40-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

2)Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% | |

6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

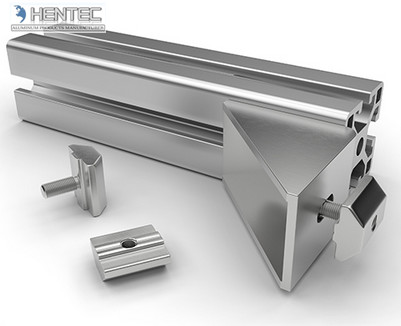

We offers over 100 Moulds for aluminum V slot & T slot profile framing systems. The Advantage of using our standard aluminum profile are:

1. Saving mould cost and shorten production time;

2. Shorting design and assembling time;

3. Associated accessories are available as well to save your time to resource it;

4. Controlling cost and providing more efficient working project;

5. Improving your systems and space management with our professional technical team.

|