| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Casting Sand |

|---|---|

| Brand Name: | VOBEN |

| Model Number: | 30-60 Mesh |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 15ton |

| Price: | US$300-500/Ton FOB Qingdao |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50,000-100,000 Mts Per Year |

| Delivery Time: | 30days |

| Packaging Details: | 25 kgs in plastic bag, 40 bags/Pallet ,1000kg/bag, |

| Color: | White or Gray |

| Material: | Mullite |

| AL2O3 mix: | 43-46% |

| SIO2 mix: | 50.5-52.5% |

| Fe2O3 max: | 1.2-2.3% |

| Tio2 max: | 0.7-1.0% |

| B.D.g/ccm m: | 2.5-2.55% |

| Refractory Index: | 1750 |

| Usage: | Investment Casting |

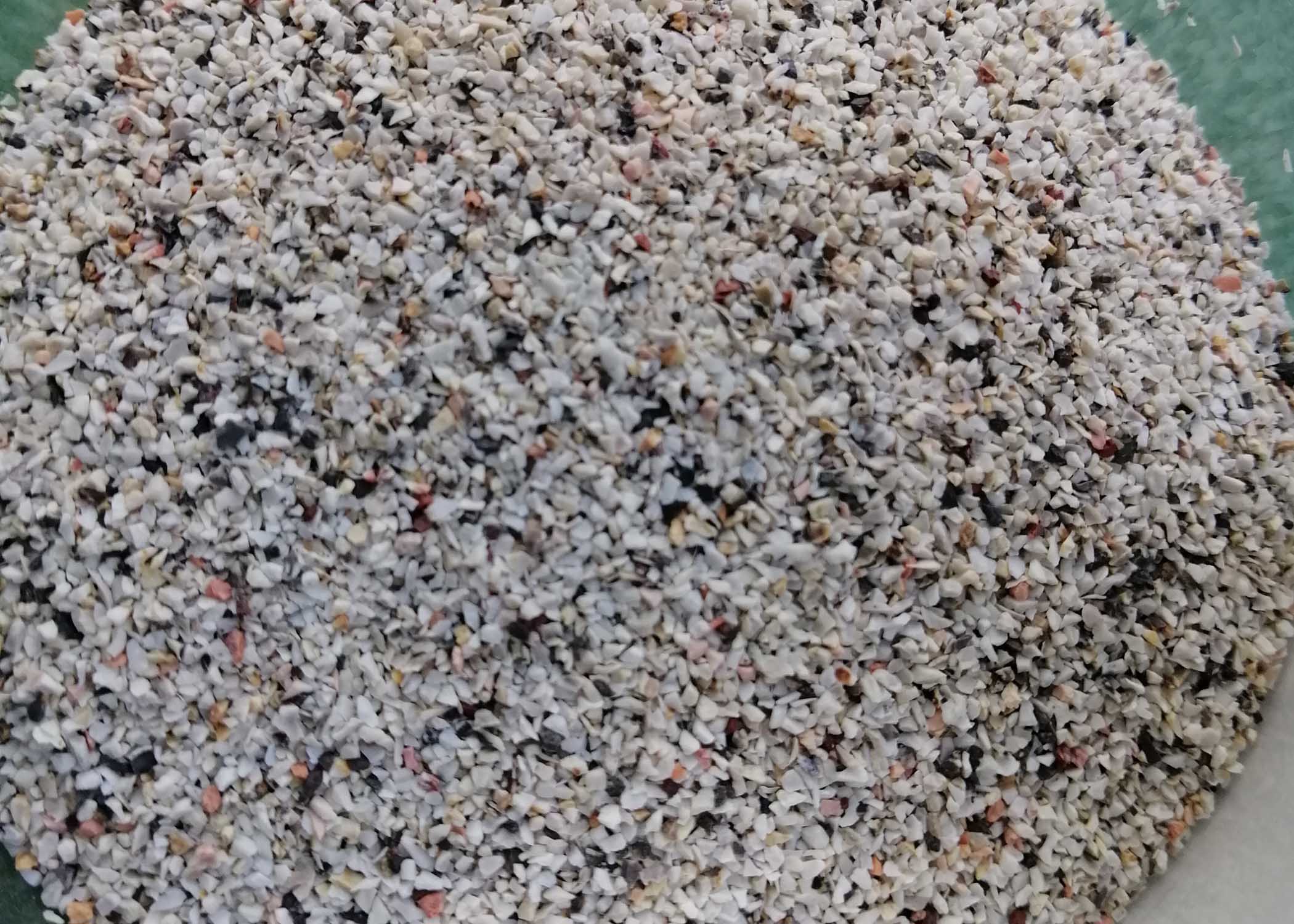

| Appearance: | Granular or powder |

| Particle Size: | 0.3mm-0.6mm>65-75% |

30-60 Mesh High-alumina Casting Sands With Low Thermal Expansion Coefficient Precision Investment

1. Description:

a. Our products are made of mullite or kaolin raw ore.

b. The density of mullite, the raw material of casting sand, is

usually greater than 2.5g / m3, the true specific gravity is 2.6g /

cm3, the water content is less than 0.03%, and the fire resistance

is greater than 1750 ° C.

c. The weight of mullite will be reduced by 0.3% to not more than

0.4% under the condition of high temperature combustion, which

indicates that the chemical properties of mullite are stable.Its pH

is between 7 and 9, and the hardness of the shell is greater than 8

MPa.The alumina content in the foundry sand is between 42% and 46%, and

the silica content is between 51% and 53%.All above make our high-alumina precision investment casting sand keep low thermal

expansiion coefficient and make the shell keep good shape.

d. The grain size and application of mullite for casting sand are

different. Mullite is made from kaolin by high temperature

sintering. The chemical composition of mullite is a chemical

substance with strong fire resistance, and its performance is

relatively stable.

e. To make the shell,in the back layer slurry, 200 mesh mullite and

silica sol are needed, and 30-60 mesh mullite is added to the

slurry.

| The physical and chemical indications | ||||||

| Grade | Fe₂O₃ % Max | Al2O3 % min | SiO₂ % min | TiO2 % max | B.D.g/ccm min | refractoriness |

| Ⅰ-Ⅲ | 1.2-2.3 | 43-46 | 50.5-52.5 | 0.7-1.0 | 2.5-2.55 | 1750 |

3. Product Application:

More Products Pictures

1. 30-60Mesh Grade Ⅰ

| The physical and chemical indications | ||||||

| Grade | Fe₂O₃ % Max | Al2O3 % min | SiO₂ % min | TiO2 % max | B.D.g/ccm min | refractoriness |

| Ⅰ | 1.2 | 46 | 50.5 | 0.7 | 2.55 | 1750 |

2. 30-60Mesh Grade Ⅱ

| The physical and chemical indications | ||||||

| Grade | Fe₂O₃ % Max | Al2O3 % min | SiO₂ % min | TiO2 % max | B.D.g/ccm min | refractoriness |

| Ⅱ | 1.5 | 44 | 51.5 | 0.9 | 2.53 | 1750 |

3. 30-60 Mesh Grade Ⅲ

| The physical and chemical indications | ||||||

| Grade | Fe₂O₃ % Max | Al2O3 % min | SiO₂ % min | TiO2 % max | B.D.g/ccm min | refractoriness |

| Ⅲ | 2.3 | 43 | 52.5 | 1 | 2.5 | 1750 |

|