| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Can Filling Machine |

|---|---|

| Brand Name: | DMK |

| Model Number: | DGF12-1 |

| Place of Origin: | Zhangjiagang city |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 sets per year |

| Delivery Time: | 45 working days |

| Packaging Details: | Standard export packing |

| Name: | Can filling machine |

| Capacity: | 1500-2000 cans per hour(330ML can) |

| Material: | Stainless steel |

| Power: | 3.5KW |

| Weight: | 3000KG |

| Size: | (L*W*H)1500*1950*2200mm |

| Function: | Filling Sealing 2 in 1 |

| Control: | PLC+Touch screen |

| Filling head: | 12 heads |

| Capping head: | 1 pcs sealing |

| Company Info. |

| Suzhou Drimaker Machinery Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

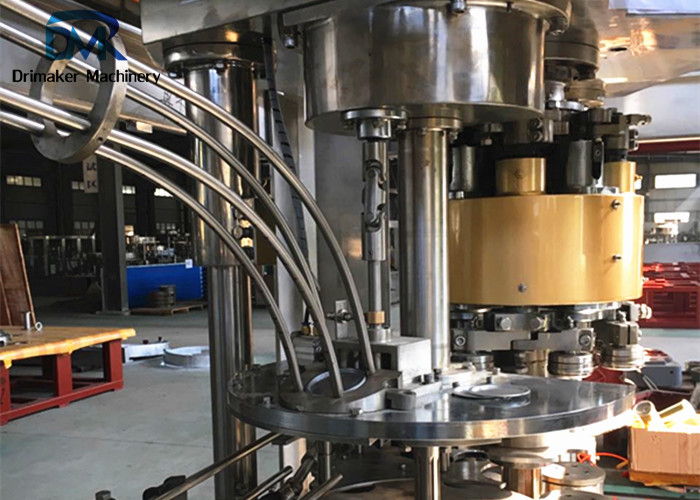

Beer Can Factory Aluminum Can Filling Machine 2000 Pcs Per Hour

Capacity

Can filling machine description:

This type DGF12-1 filling sealing 2 in 1 monoblock is mainly used

in soda production enterprise, is a special cans for automatically

filling and sealing equipment. By delivery of the cans

automatically into machine, automatic filling, automatic

sealing,automatic outlet conveying process, improving the labor

productivity, ensure the quality of for soda filling, which is also

the core machine of the soda packaging production line.

Can filling machine material:

1. Transmission components: high quality carbon steel, the dial for

polymer materials.

2. Filling valve assembly: SUS304 stainless steel, silicone rubber.

3. Filling tank: SUS304 stainless steel.

4. Filling parts: pneumatic control, SUS304 stainless steel.

5. Conveyor belt parts: the side plate is SUS304 stainless steel, and the conveyor chain is POM flat-top chain.

6. Work table components: the frame is carbon steel structure, the outer SUS304 stainless steel protective plate.

7. Sealing parts: high quality carbon steel, bearing steel, tool steel.

Can filling machine electrical configuration:

| No | Name | Brand | Origin |

| 1 | PLC | Mitsubishi | Japan |

| 2 | Frequency converter | Mitsubishi | Japan |

| 3 | Touch screen | Weinview | Taiwan |

| 4 | Contactor | Schneider | French |

| 5 | Photoelectricity | Omron | Japan |

| 6 | Pneumatic | Airtac | Taiwan |

| 7 | Air switch | Omron | Japan |

Can filling machine details description:

Can filling:

It adopts isobaric filling, to make sure and control the air pressure in filling tank and can side. When empty can enter into the filling position, the can holder will fix and lift up the empty can, to open the filling valve. CO2 air will be injected into empty can first to make sure air pressure is same with filling tank, then liquid will be filled into the can.

Sealing:

Cap of can will be put on the empty can during the can moving. then sealing wheel will seal the can in one circle automatically, make sure the sealing situation of can. No gas no liquid will be out of can after sealing.

Thanks!

For more information please contact us!

|