| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tumbler Screening Machine |

|---|---|

| Brand Name: | AAREAL |

| Model Number: | AM |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 20~35 work days after order confirmed |

| Packaging Details: | Fumigation-free plywood wooden case for export |

| Motion: | imitate the manual screening action, involute spiral motion |

| Other Names: | tumbler screener, tumbler screening machine, tumbler screen, tumbling screen, tumbler sieve, swing sieve, swinging sieve, shaking sieve etc. |

| Screen Decks: | 1~5 decks |

| Screening Efficiency: | up to 90~99% |

| Mesh Cleaning Method: | ultrasonic system, self-cleaning ball system, rolling brush, air brush etc. |

| Diameter: | 600mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm etc. |

| Application: | aluminum oxide, ceramic glazes, food flour, micronised materials, mineral powders, plastic powders, plastic powder, glass beads, xylitol, citric acid, food additives, calcium carbonate etc. |

| Optional Parts: | pneumatic lifting devices, quick clamps etc. |

| Company Info. |

| Xinxiang AAREAL Machine Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Aluminum Oxide Vibratory Screen Separator Low Noise Vibrating Screen Machine

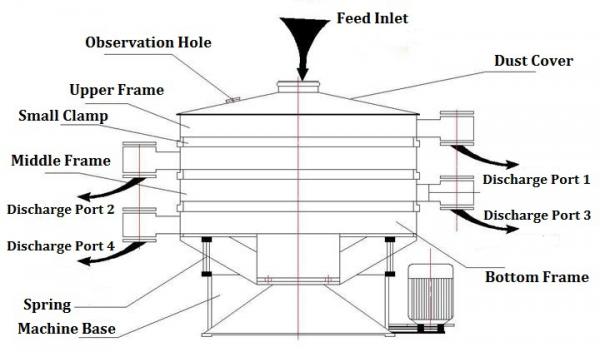

Overview of Tumbling Screener Machines for Aluminum Oxide:

The tumbling screener machines are also known as tumbler screen, tumbler screener, tumbler screening machine, tumbling screen machine, swing sieve, swinging sieve, shaking sieve etc. The tumbler screening machine is used for control screening, fractionating and dust removal in dry, powdered and granular products. It is typically used to sieve extremely ine and/or lightweight products, such as food flour, micronised materials, mineral powders, plastic powders etc.

The tumbler screening machine is an efficient sieving equipment which is designed to meet the large out put, high-density sieving of the manufacturers. It is the most effective simulation of artificial sieving movement (sieving precision, efficiency, service life is 5~10 times than the common cylinder sieve), for the processing of all the fine and ultra-fine powder and specialmaterials, particularly suitable for materials which are difficult to classify.

Working Principle of Tumbling Screener Machines for Aluminum Oxide:

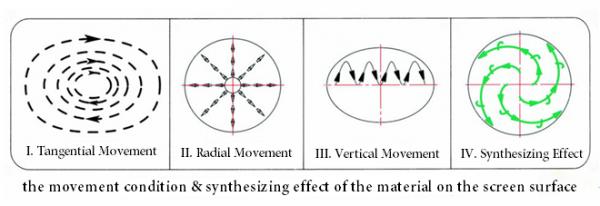

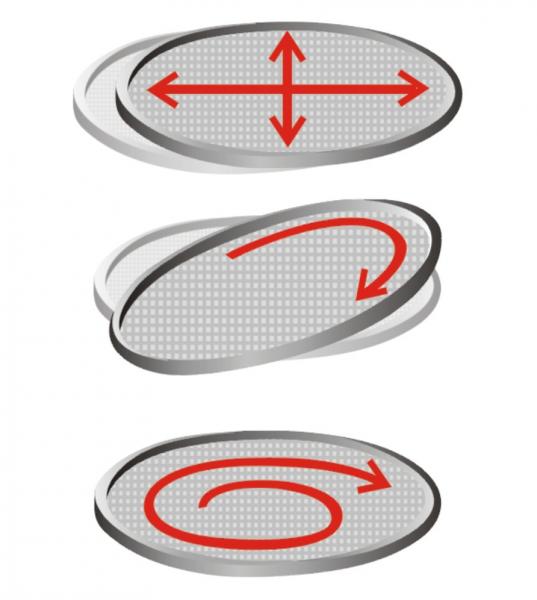

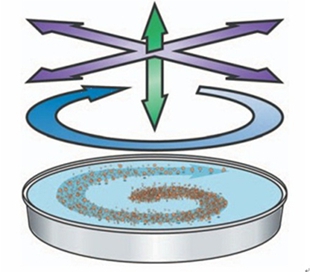

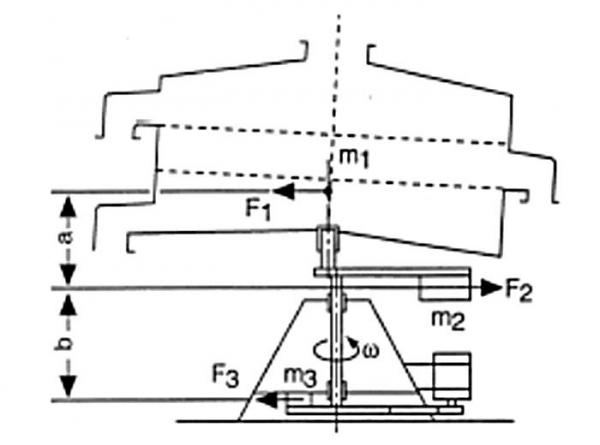

The tumbler screening machine has a three-dimensional movement similar to the simple hand screening. This tumbling action yeilds better efficiency and a higher specific screen load as compared to vibration systems.

The tumbler screener utilizes the humanoid screening principle. To imitate the movement of artificial screening action and do three-dimensional circular motion, skillfully combine the sieving (planar circular motion) and winnowing (upward parabolic motion), establish horizontal and throwing three-dimensional tumbling movement, make the material in the screen surface appear involute spiral movement. The material takes a relatively long distance across the relative area, and the landing screen time of the material is more than 85%, improving the screen through rate. The screening accuracy is as high as 90%~99%, increasing the yield.

Important Information About Tumbling Screener Machines for Aluminum Oxide You May Want to Know:

| Motion | involute spiral motion |

| Screening Accuracy | upto 90%~99.9% |

| Mesh Cleaning Method | bouncing ball cleaning, ultrasonic cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen |

| Diameter | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | quick clamps, pneumatic lifting devices etc. |

| Application | can be used for material that is flammable, explosive and easy to generate static |

Features of Tumbling Screener Machines for Aluminum Oxide:

Technical Parameters of Tumbling Screener Machines for Aluminum Oxide:

| Model | Screen Area (m²) | Layers of Screen | Motor Power (KW) |

| AM-600 | 0.28 | 1~5 | 0.25 |

| AM-1000 | 0.72 | 1~5 | 1.5 |

| AM-1200 | 1.10 | 1~5 | 1.5 |

| AM-1500 | 1.80 | 1~5 | 2.2 |

| AM-1800 | 2.30 | 1~5 | 4.0 |

| AM-2000 | 2.60 | 1~5 | 4.0 |

| AM-2300 | 3.90 | 1~5 | 4.0 |

| AM-2600 | 5.30 | 1~5 | 5.5 |

| AM-2900 | 6.40 | 1~5 | 5.5 |

Application of Tumbling Screener Machines:

1. Food industry

2. Dairy farming

3. Chemical Industry

4. Pharmaceutical Industry

5. Recycling and environmental

6. Plastic materials

7. Agriculture

8. Confectionery industry

9. Cement and sand

10. Metal processing industry

11. Wood industry

12. Diamond cutting and grinding tools

Pneumatic Lifting Device BALANCE IS IMPORTANT !!

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

|