| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Gyratory Screen Sifter |

|---|---|

| Brand Name: | AAREAL |

| Model Number: | AD |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 15~35 work days after order confirmed |

| Packaging Details: | Plastic film for the machine body, and fumigation-free plywood wooden case for the spare parts such as screens etc. |

| Movement: | circular-elliptical-linear motion |

| Biggest Model: | AD-2050 (screen width*length 2000mm*5000mm) |

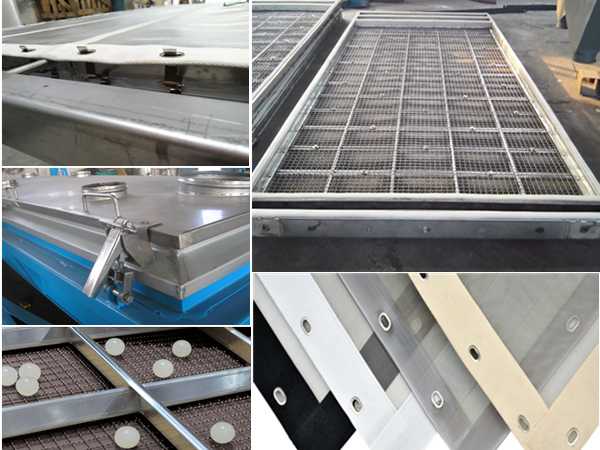

| De-blinding System: | rubber balls, silicone balls etc. |

| Screen: | stainless steel automatically tensioned screen, made by ourselves |

| Drag Link: | drag link assemblies, made by ourselves |

| Compensating Clamps: | clamp handle assemblies, made by ourselves |

| Clips: | 3 kinds of clips, made by ourselves |

| Installation: | cable suspension, floor mounting |

| Company Info. |

| Xinxiang AAREAL Machine Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Introduction of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

Do you want High Precision Industrial Gyratory Screening Equiment for Compound Fertilizer? Our gyratory screen can reach large screening capacity and above 90% screening accuracy for the compound fertilizer. The gyratory screening equipment is also called gyratory screen, gyratory screener, Rotex screen, Rotex screening machine, Rotex separator, gyratory separator, gyratory sifter, gyratory screening machine, planar rotary screen, plane rotary screen, rotary flat sieve, flat screen, square precision screening machine, reciprocating screen etc.

Our AD model gyratory screener is one of the best seller of our company compare with other kinds of sieving equipments such as rotary vibrating screen, linear vibrating screen etc.. And the performance of this gyratory screen have been proven by many customers in different industry applications.

Useful Information You Can't Miss About Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

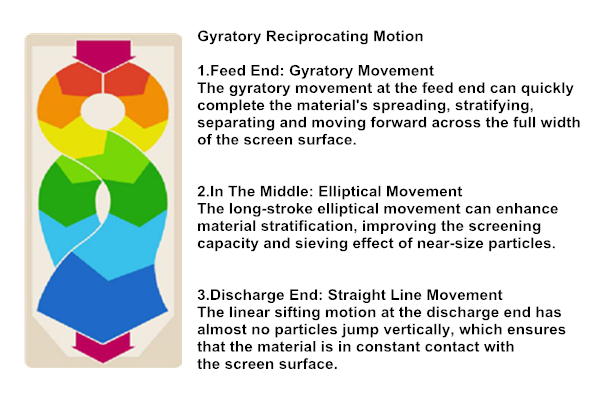

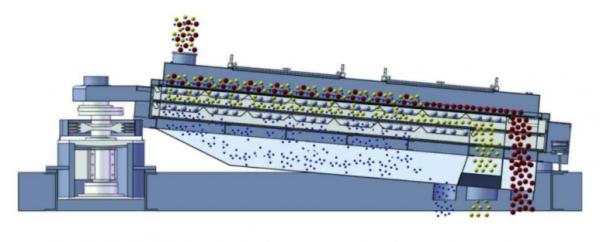

| Moving Trajectory | gyratory reciprocating motion: circular motion at feed end, elliptical motion at center, and linear motion at discharge end |

| Drive Device | general motor + exciter + belt |

| Layers of Screen | 1~4 layers of screen available |

| Screen Size | upper screen width*length 500*1500mm, 1000*2100mm, 1000*3000mm, 1500*3000mm, 1500*3600mm, 1800*3600mm, 1800*4000mm, 2000*5000mm etc. |

| Motor Brand | Siemens, ABB, or according to customer requirements |

| Spare Parts | the special screen, drive exciter, drag link, compensating clamps, clips are made by ourselves |

| Discharge Port | usually at the bottom of the machine, and it can also be made at the back of the machine |

| Material | carbon steel, stainless steel, aluminium etc. |

| Installation | floor seat installation, cable suspension installation |

| Mesh Cleaning Method | use mesh cleaning balls to clean the screen mesh. Rubber ball, silicone ball, polyurethane ball etc. |

Working Principle of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

1. Circular motion at feed end

The gyratory motion at the feed end of the machine immediately spreads the material across the full width of the screen surface to maximize screen utilization even though the feed is from a single point. At the same time, this motion stratifies the material, causing the fines to sink down against the screen surface. The particles that are appreciably smaller than the openings quickly pass through at this part of the screen.

2. Changing to elliptical motion at center

As the circular motion diminishes into an elliptical path, the gentle near-horizontal motion causes the fine particles closer in size to the screen mesh the near-size particles to fall through the mesh openings.

3. Straight-line motion at discharge end

The nearly linear reciprocating motion at the discharge end of the Gyratory Screener removes those particles closest in size to the mesh openings while gently conveying the oversize material off the screen.

Advantages of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

1. The screen deck of gyratory screening equipment consist of mesh,

spring clamp, ball trays and self-cleaning balls. The self-cleaning

balls jump ceaselessly along with gyratory screen operation, the

ball could hit the screen mesh in order to let the mesh vibration,

so the material blocked in the mesh aperture or adhered to the mesh

surface will be cleaned out, it could make sure the aperture ratio

so guarantee the screening efficiency.

2. The gyratory screen do not have vertical vibration, so it do not have much load request on the base foundation, it is much lower than the vibration type screening machine, so the gyratory screener could save steel structure cost, the customer do not need to consider the install load limited.

3. The materials do the reciprocating-gyratory motion along with the gyratory screen running, and there is not vertical jump during the gyratory screen running period, the little size material will go to the bottom of the flow bed along moving forward, the material particle will pass the mesh aperture when the particle size is less than the gyratory sifter aperture size. The reciprocating gyratory motion will make the material flow bed touch the screener mesh surface with longer time for increasing the screening efficiency.

4. The reciprocating gyratory motion of the Rotex gyratory screener will spread the material flow bed evenly along with the screener mesh bed after material fall into the inlet, the material flow bed will be very thin after being spread, it is good for material screening , and the material screening precision and capacity will be increased.

Technical Parameters of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

There are different models of Rotex Type Gyratory Vibrating Screen Sifter for your reference, and we will choose a suitable model according to your specific materials and application.

Layers | Model | Screen Surface Specification (W*L) (mm) | Screen Box Stroke (mm) | Motor | A (mm) | B (mm) | C (mm) | D (mm) | Weight (kg) | |

Power (kw) | Rotation Rate (rpm) | |||||||||

| 1 | AD-1014-1 | 1000*1400 | 63.5 | 1.5 | 960 | 2731 | 962 | 1168 | 1200 | 715 |

| AD-1021-1 | 1000*2100 | 63.5 | 1.5 | 960 | 3285 | 962 | 1156 | 1200 | 980 | |

| AD-1030-1 | 1000*3000 | 63.5 | 1.5 | 960 | 4484 | 1035 | 1194 | 1251 | 1200 | |

| AD-1521-1 | 1500*2100 | 63.5 | 1.5 | 960 | 3460 | 1003 | 1708 | 1759 | 1380 | |

| AD-1530-1 | 1500*3000 | 76 | 2.2 | 960 | 4232 | 1362 | 1778 | 1892 | 1340 | |

| AD-1536-1 | 1500*3600 | 76 | 5.5 | 960 | 5098 | 1352 | 1956 | 2048 | 2410 | |

| 2 | AD-1236-2 | 1200*3600 | 76 | 5.5 | 960 | 5263 | 1327 | 2464 | 2556 | 2020 |

| AD-1021-2 | 1000*2100 | 63.5 | 1.5 | 960 | 3743 | 1121 | 1308 | 1378 | 1400 | |

| AD-1030-2 | 1000*3000 | 76 | 4 | 960 | 4575 | 1317 | 1270 | 1546 | 1840 | |

| AD-1521-2 | 1500*2100 | 63.5 | 4 | 960 | 3728 | 1330 | 1781 | 1946 | 1710 | |

| AD-1836-2 | 1800*3600 | 76 | 7.5 | 960 | 5305 | 1500 | 2256 | 2459 | 3880 | |

| AD-1530-2 | 1500*3000 | 76 | 7.5 | 960 | 4765 | 1397 | 1956 | 2159 | 2780 | |

| AD-1536-2 | 1500*3600 | 76 | 7.5 | 960 | 5365 | 1368 | 2032 | 2019 | 3180 | |

3 | AD-1021-3 | 1000*2100 | 63.5 | 5.5 | 960 | 4854 | 1422 | 1435 | 1549 | 2150 |

| AD-1530-3 | 1500*3000 | 76 | 5.5 | 960 | 4765 | 1391 | 1956 | 2159 | 3200 | |

| AD-1836-3 | 1800*3600 | 76 | 7.5 | 960 | 5200 | 1500 | 2400 | 2500 | 4170 | |

| AD-2050-3 | 2000*5000 | 92 | 11 | 960 | 5400 | 2000 | 2750 | 2810 | 5500 | |

Application of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

Fertilizer: urea, compound fertilizer etc., raw material sieving and finished product fine screening.

Carbon products: coking coal, graphite, charcoal etc.

Chemical products: hundreds of different compounds

Clay: product classification

Fiberboard: wood chips, flaking, bits of wood, to make high quality fiberboard

Drug: many large drug manufacturers use our screening machines, which meet the health standard design and GMP, to achieve precise and effectiveseparation and cleaning

Plastic: plastic particles, plastic powder

Powder metal: aluminum, copper, iron, nickel, steel, zinc and many other metal powders

Recycling of resources: used in the recycling of various materials, such as PET recycling etc.

Abrasive: glass beads, slag, alumina, sand and other abrasive materials

Animal feed: feed powder and chips, meat paste and small food

Paper: paper pulp, coating

Steel-making: classification of steel shot and metal filing

Including ammonium nitrate, phosphate, potassium hydroxide, urea and other compounds

Food: sugar, flour, milk powder, coffee, cereals, rice, nuts, condiments, cocoa powder, glucose, starch etc.

Grain cleaning: corn, wheat, soybean and other cereals peeling and cleaning

Ore: ore, rubble, limestone, soda ash and salt

Installation of Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

1. Floor Mounting or Seat Installation:

Forward Type (the outlet is at the back) Direct Discharge Type

2. Cable Suspension Installation:

Cable Suspension Type

Some Spare Parts for Coconut Shell Activated Carbon Gyratory Screening Sifter with High Accuracy:

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

|