| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

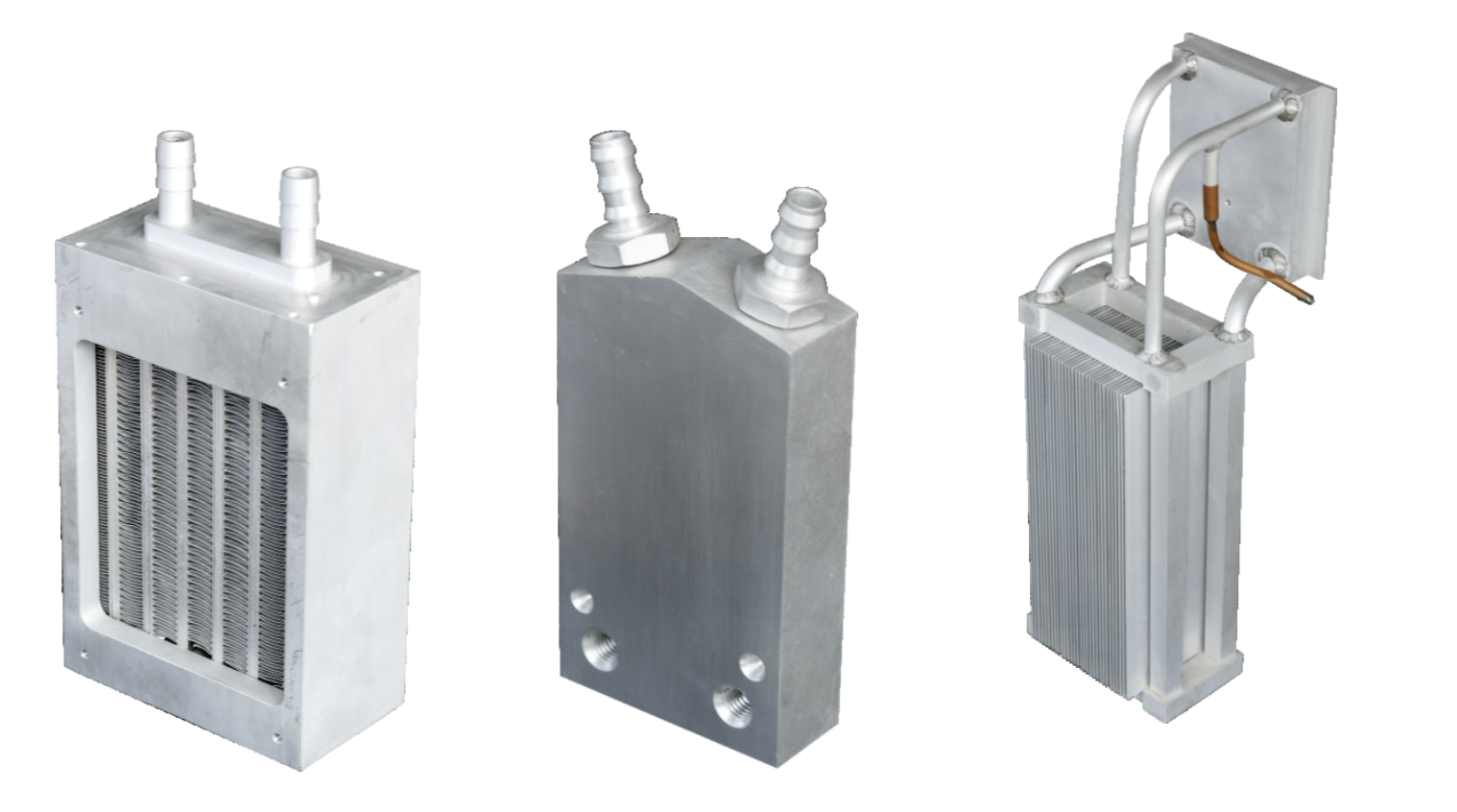

| Categories | Liquid Cold Plates |

|---|---|

| Brand Name: | ADV |

| Model Number: | ADV -CD-002 |

| Certification: | ISO9001 |

| Place of Origin: | Changzhou China |

| MOQ: | 1 Unit |

| Supply Ability: | 1~50 + Units + 25 Working Days |

| Delivery Time: | 7~15 Working Days |

| Packaging Details: | Wooden Packing |

| Product: | Heat Exchanger For Laser Equipment |

| Material: | AL3003 |

| Technic: | Vacuum Brazing & FSW Welding |

| Max Size: | 1000*1600 |

| Max Test Pressure: | 3.5 Mpa |

| Test: | Leak Test & Performance Test & Pressure Pulse Test & Vibration Test |

| Usage: | Precision Welding Cooler Communication Base Station Cooler Air to Air Cooler Laser Machinery Cooler Diode Cooling Wind Powder Generation Convert Cooler Electronic Car Battery Cooling Air to Air Cooler cooling laser machine cooling system deode cooler Conv |

| Warranty: | 12 Month |

| Application: | High-powered laser equipment cooling |

Description

The performance of high-powered lasers depends on effective cooling. High-powered lasers generate a significant amount of heat that must be removed from the laser system to avoid overheating critical components. Carbon dioxide (CO2) lasers, excimer lasers, ion lasers, solid-state lasers, and dye lasers all use liquid cooling to remove excess heat.

air to air heat exchangers for laser equipment

Air to air heat exchanger for High Power Laser Equipment

Product Feature

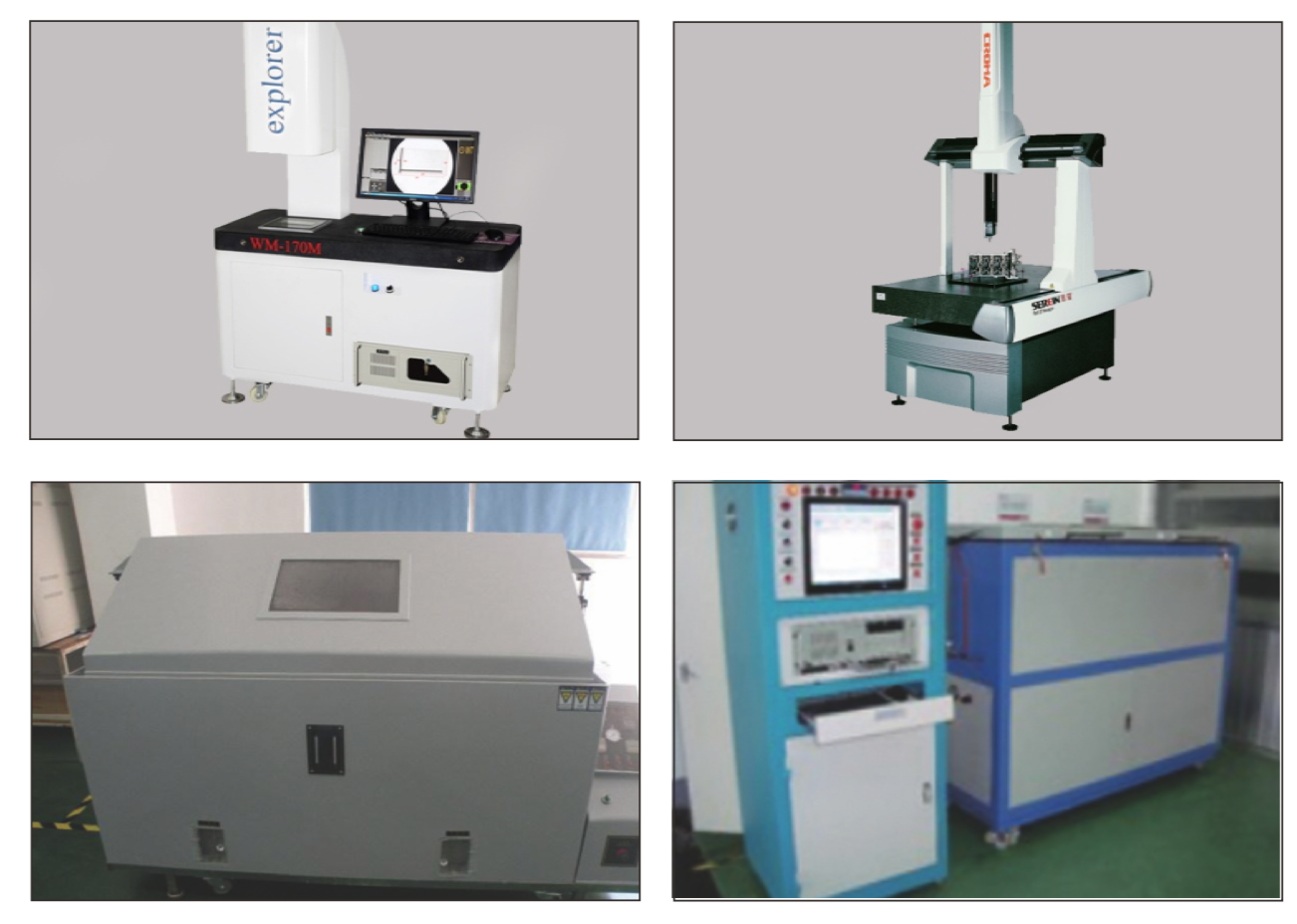

Manufacturing

Precise Machining Work Shop

Friction stir welding cold plate

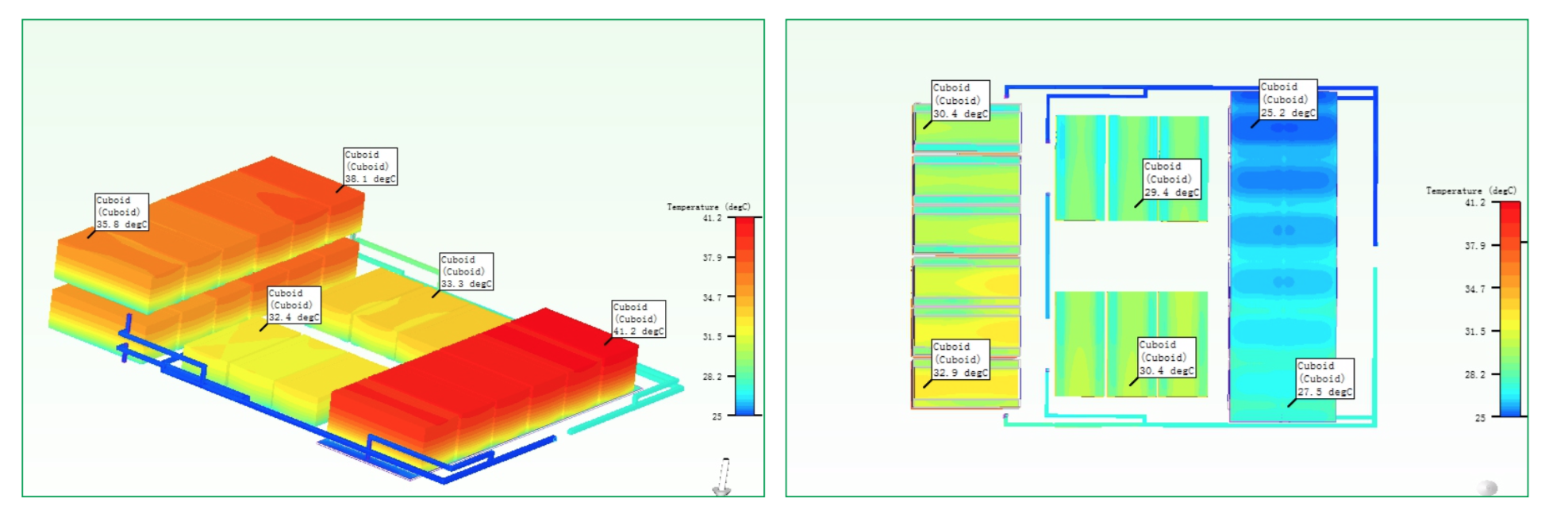

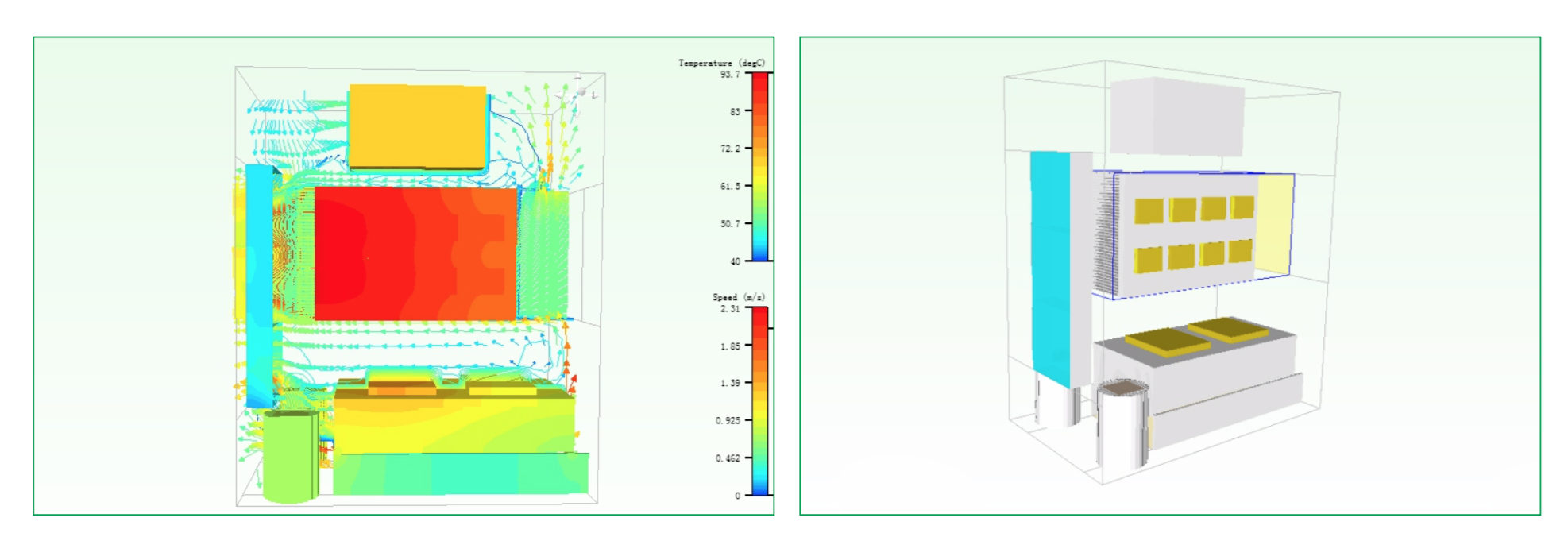

R & D

Cold Plate Simulation

Please be free to contact us if you need any further information, thank you!

|