| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicone Auto Parts Making Machine |

|---|---|

| Brand Name: | TYM |

| Model Number: | w4545 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 10000sets/year |

| Delivery Time: | 60 work days |

| Packaging Details: | Standard plywood case or based on the detailed request of our client |

| Injection Rate: | 30g/s |

| Injection Pressure: | 700kg/cm2 |

| Clamping Force: | 130T |

| Ejection Force: | 4.3T |

| Motor Power: | 12.1KW |

| Pump Pressure: | 21Mpa |

| Ejection Stroke: | 150mm |

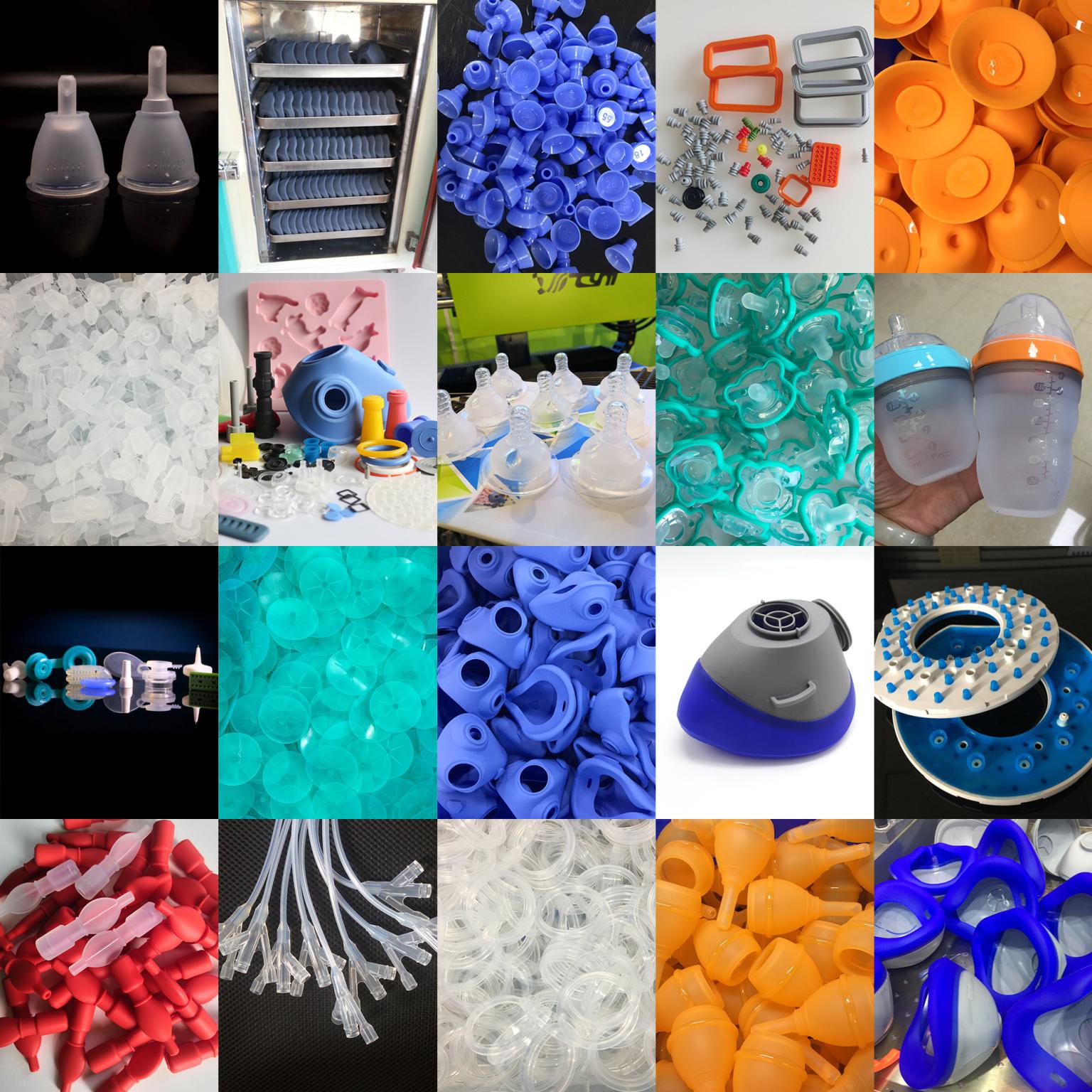

TYM rubber injection moulding machine TYM-W4545 horizontal machine open and close mold horizontally , more suitable for fully automatic demolded silicone product production to meet the automatic production.

TYM professionally rubber injection moulding machine only have one control panel computer , more efficient , more energy efficient , save more production cost. Match with TYM color slurry pump , computer control color slurry input , accuracy up to 0.01G, very easy to operate .

Product Features

Liquid silicone rubber is divided into glue a and glue B. the ratio of the two is controlled by a quantitative device to be 1:1, and then it is fully mixed through a static mixer, injected into the discharge tube, and then produced by injection molding

| Machine Model | Shot Volume | Injection Rate | Injection Pressure | Clamping Force | Opening Stroke | Tie-Bars Space | Ejection Force | Machine Weight | Motor Power |

| TYM-L5058 | 165g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 500*580MM | 4.3T | 5.3T | 12.1kw |

| TYM-L6068 | 300g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 600*680MM | 4.3T | 5.5T | 12.1kw |

| TYM-W4545 | 165g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 450*450MM | 4.3T | 5.2T | 12.1kw |

| TYM-W5050 | 300g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 500*500MM | 4.3T | 5.3T | 12.1kw |

Liquid silicon rubber is a kind of non-toxic, heat-resistant and high resilience flexible thermosetting material. Its rheological behavior mainly includes low viscosity, rapid curing, shear thinning and high thermal expansion coefficient.

LSR is a double liquid fast curing material with platinum as catalyst, which can be produced by injection molding, large-scale, fast curing and repetitive machinery. Its products are characterized by good thermal stability, cold resistance, excellent electrical insulation performance, and no toxic substances produced during combustion.

Therefore, it has become an irreplaceable material in the production and design of health products, automobiles, baby products, medical products, diving products, kitchen appliances and seals.

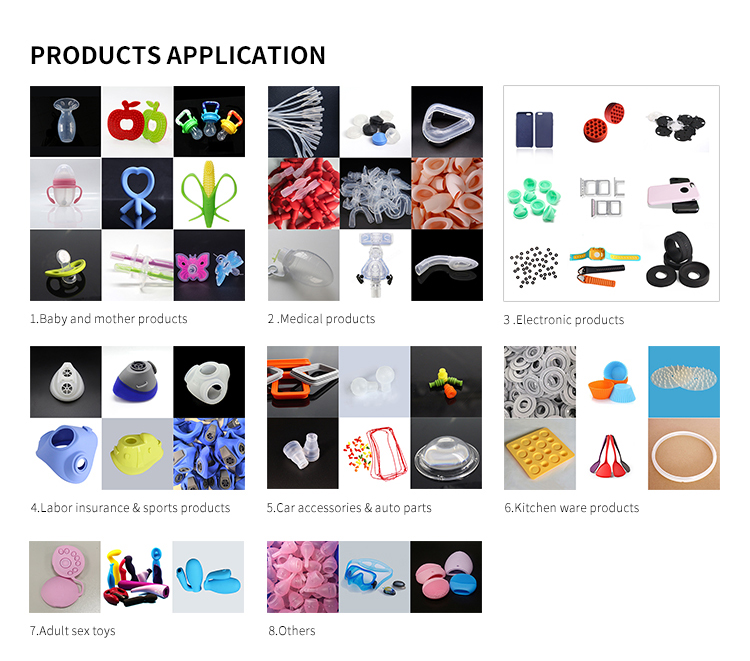

Applications

Our LSR injection molding machine is widely used in medical industry, food industry, infant industry, diving industry, insulator industry and other LSR production field. Furthermore, with abundant technical strength,Tianyuan can design the LSR injection molding equipment exactly based on the customer's requirements, and can provide the turn-key solutions, such as the LSR feeding machine, LSR injection molding machine, LSR mixing system, color adding system, LSR mould and so on.

Certificate

TYM have More than 60 patents , 12 invention patents, it is rated as a national high-tech enterprise in 2013 .

Our Services

Pre-sale service

According to customer's investment budget, plant planning and other forms of pre-sales services to ensure customer's planning is reasonable, standardized and cost-saving and provide matched mold scheme and recommend suitable machine according to customer's product.

On-purchase service

Enable the relevant personnel to be familiar with the operation of the TYM's machinery and understanding the machine maintenance.

1) Installation of LSR machine and new machine commissioning service

2) Machine operator training

3) Training of relevant technicians

After-sales service

1) Free training till relevant personnel is able to operate and maintain independently

2) Help to solve and reply technical problem and question timely, TYM will arrange professional engineer for site instruction

3) TYM will provide technical guidance for free if customer need new equipment or expand(rebuild)

4) TYM will give priority to customer according to customer's upgraded demand when TYM's equipment is upgraded.

|

|