| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Wire Mesh Filter Disc |

|---|---|

| Brand Name: | BJPFM |

| Model Number: | PFM- Sintered Filter Disc |

| Certification: | SGS |

| Place of Origin: | China |

| MOQ: | 10 PCS |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 100000 Pcs/Month |

| Delivery Time: | 7-15 days after payment |

| Packaging Details: | Standard export packing in carton or wooden box, or as your specific requirement. |

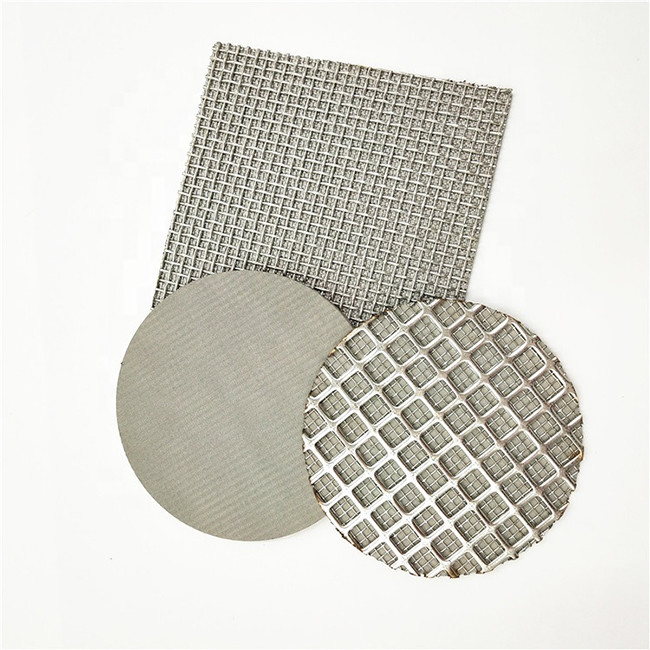

| Product name: | Sintered Filter Disc |

| Usage: | Air Filter, Liquid Filter |

| Material: | Stainless steel 304, 316, 316L, Hastelloy, Monel, Incone |

| Thickness: | 1-5mm, 1.7MM |

| Filter Rate: | 1-400um |

| Technique: | Sintered Wire Mesh |

| Feature: | Corrosion Resistance |

| Application: | Kinds Filtration Industry |

| Company Info. |

| Beijing PFM Screen Co., Ltd. |

| View Contact Details |

| Product List |

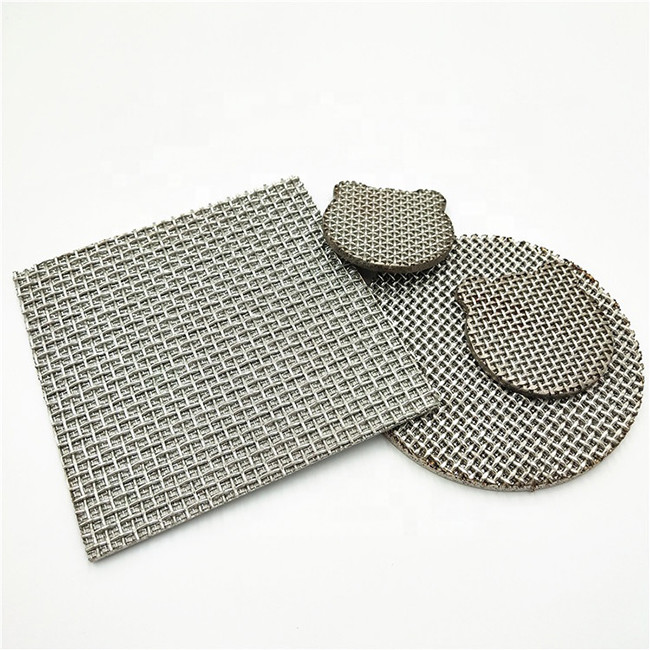

The multi-layer sintered metal mesh is a new type of filter material which is made of a multi-layer metal woven wire mesh and is manufactured by a special lamination pressing and vacuum sintering process and has high mechanical strength and an overall rigid structure.

1. High strength and good rigidity: It has high mechanical strength and compressive strength, and has good processing, welding and assembly performance and is easy to use.

2. Uniform and stable accuracy: Uniform filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

3. Wide use environment: It can be used in the temperature environment of -200 ° C ~ 600 ° C and filtration of acid and alkali environment.

4. Excellent cleaning performance: good counter-current cleaning effect, can be used repeatedly, long life (can be washed by countercurrent water, filtrate, ultrasonic, melting, baking, etc

4. Sintered Filter Disc Application

1. Precision filtration of various hydraulic oil lubricants in the machinery industry;

2. Filtration and purification of various polymer melts in the chemical fiber film industry, various high temperature in the petrochemical industry, filtration of corrosive liquids, filtration, washing and drying of materials in the pharmaceutical industry;

3. Application of gas homogenization in the powder industry, fluidized plates in the steel industry;

4. Sounders in explosion-proof electrical appliances, etc.

|