| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | LSR Liquid Silicone Rubber |

|---|---|

| Brand Name: | RUI - HE |

| Model Number: | RH20191227-4 |

| Certification: | FAD.MSDS. ROHS.LFGB. ISO 9001:2015 |

| Place of Origin: | GuangZhou, China |

| MOQ: | 100KG |

| Price: | USD/per Kilograms |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 1000 tons per month |

| Delivery Time: | 5 -15 days |

| Packaging Details: | 20kg pails OR 200Kg / drums |

| Sample: | Available |

| Ratio: | 1:1/10:1 |

| Feature: | Food Grade |

| Cure time: | surface 1 hours, post cured 10-24 hours |

| Usage: | silicone mold chocolate,Microwave,ice tray mould |

| Hardness: | 20-60 Shore A |

| Features: | Body Safe |

| Output: | 30000 tons per year |

| Material: | 100% Silicone Material |

| Company Info. |

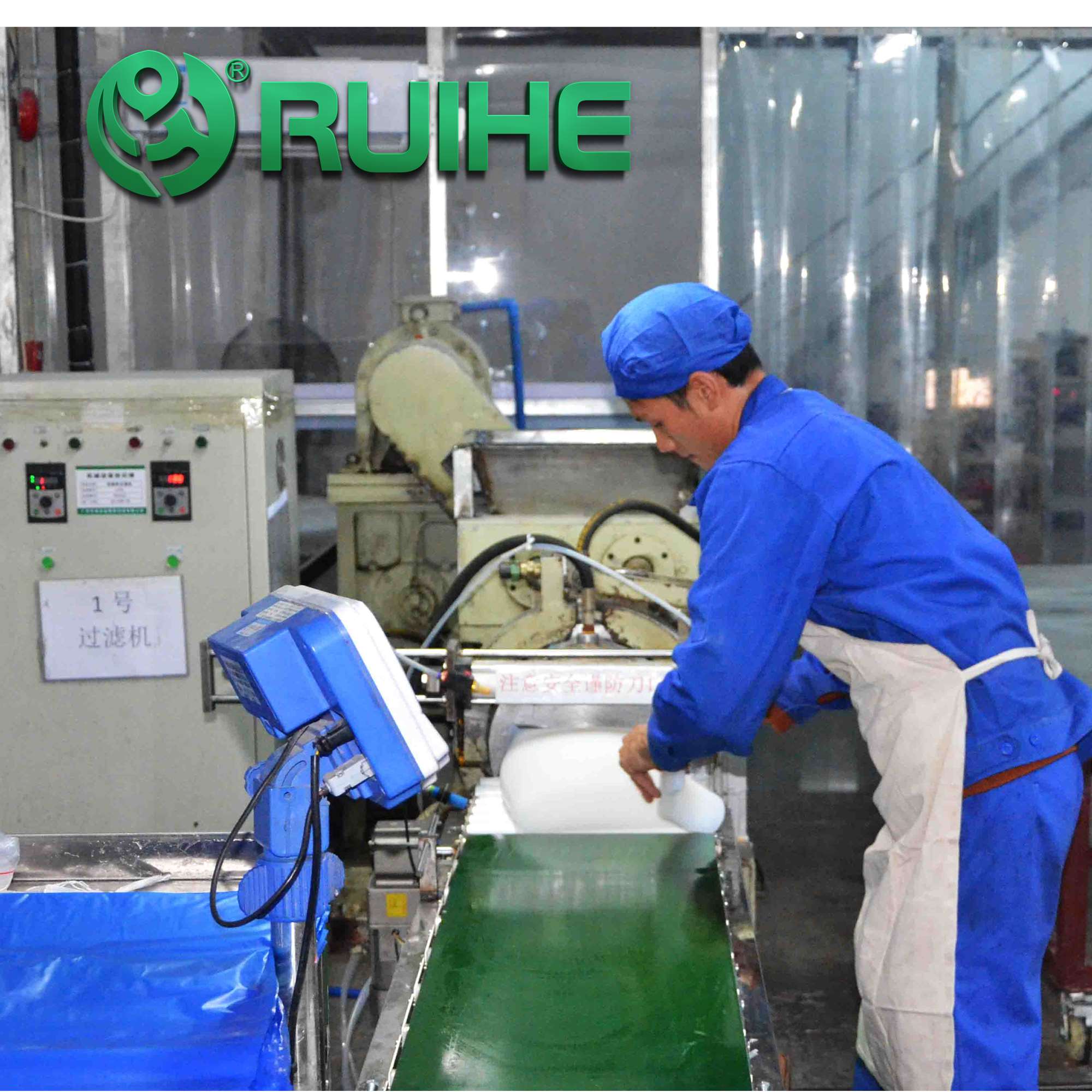

| Guangzhou Ruihe New Material Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Ruihe® - Liquid Silicone Rubber for Food Grade Mold

Additives include stabilizers, masticating aids and colorants.

To become an elastomeric material, raw silicone rubber has always to be cured. This can be done either by peroxide or addition curing. Peroxide curing involves the use of organic peroxides.

Features:

This product boasts a range of excellent properties, including high

transparency, high strength, good resilience, and minimal

deformation. It is also highly resistant to yellowing and aging,

ensuring long-lasting performance.

Furthermore, this product meets rigorous safety and quality

standards, including compliance with US FDA CFR 21.Part.177.2600

and European EN14350-2 Section 4.9 Volatile Compound Test

Standards, as well as European ROHS and REACH Standards.

When mixed and sealed, the A/B components have a safe operation

time of 3 days at 20°C. However, it's important to note that higher

temperatures can shorten the safe operation time.

Properties Data

| Physical properties | Testing method | Unit | RH6250-40 A/B | RH6250-50 A/B |

| Appearance | Visual inspection | / | Transparent | Transparent |

| Viscosity | DIN53019 | Pa.s | 160000-180000 | 180000-200000 |

| Hardness | GB/T 531.1 | Shore A | 40 | 50 |

| proportion | GB/T 533 | g/cm3 | - | - |

| Rebound | GB/T 1681 | % | 50 | 50 |

| Tensile Strength | GB/T 528-2009 | Mpa | 8.0 | 9.0 |

| Elongation | GB/T 528 | % | 500 | 550 |

| Tear strength | GB/T 529 | KN/m | 25 | 30 |

| Tear off permanent deformation | GB/T 528 | % | 0.8 | 0.8 |

| Linear shrinkage | CGB-T14235.4 | % | 2.1 | 2.1 |

| Remarks | Mold making | |||

This series of products is two-component addition liquid silicone

rubber, it has excellent performance of resistance to high

temperature , good weathering resistance, outstanding transparency,

high tear strength, good rebound ability , and good anti-yellow

properties.

Additive

Compared with other elastomers, silicone rubber requires few

additives because the essential properties are determined by the

siloxane polymer used. Thus, a finished polymer compound may

consist only of polymer and filler.

Particularly notable is the fact that silicone rubber is free of

curing accelerators or retarders, organic plasticizers and organic

antioxidants.

Guangzhou Rui-He New Material Scientific Co., Ltd

1. 15 years of manufacturing experience focus on silicone rubber

2. All Products shipped is Up to FDA, RoHS, Reach, LFGB, testing standard

3. Overall quality controlling procedure and perfect service to you

4. Offer to tailor the order accordance with customer's requirement in detail

5. 800 tons solid silicone rubber, 300 tons LSR silicone rubber and 200 tons silicone oil every month

6. Special organic silicon R&D team and precision inspection instruments equipped

7. Automatic manufacturing equipment adopted, which ensure the products shipped quality well largely

|

|