| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Asphalt Recycling Plant |

|---|---|

| Brand Name: | ZOOMLINE |

| Model Number: | ZAP-S/RAP |

| Certification: | CE, ISO, EAC, EMC |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets per month |

| Delivery Time: | about 40 days |

| Packaging Details: | 40HQ container |

| Product name: | Asphalt Regenerating Station; RAP Plant |

| Type: | Batch mixing, Stationary type, Recycling plant |

| Burner: | Italy EBICO, EFIC, Coal/Oil/Gas type |

| Emission: | No more than 30mg/Nm3 (bag house dust filter) |

| PLC: | Japan ORMON |

| Weighing: | Switzerland TOLEDO |

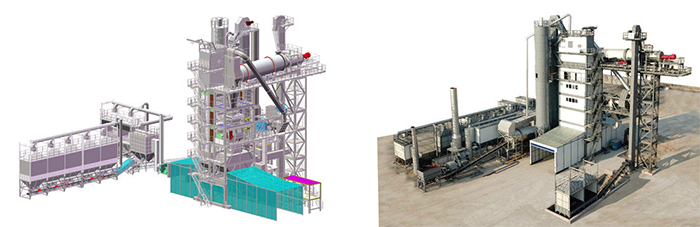

Airport Asphalt Recycling Plant RAP Asphalt Plant Asphalt Machinery

Product Description

Overview

ZOOMLINE RAP series asphalt recycling plant adopt world advanced technology, combined with decades of technical development and operational experience, solved the problems of large number of asphalt road recycling, environmental protection and cost etc.

ZOOMLINE RAP series asphalt recycling plant completely solved the technical problems of easy regeneration of aging, adhesion etc. during the old asphalt heating process. The max thermal regeneration adding proportion can reach 60% which make the asphalt recycling plant is the ideal choice for big and middle road maintenance units.

ZOOMLINE RAP series asphalt recycling plant mainly including: cold aggregate supply system, elevator, drying drum, burner, RAP conveying belt and storage bin, dust collecting system and control system.

Features

- The RAP aggregate adding rate can reach 30% to 60%.

- Blade design of drying drum is reasonable, high heat exchange efficiency, easy to replace.

- Asphalt flue gas after the cyclone dust collector is introduced to drying drum of asphalt mixing plant for secondary combustion; reduce the pollution of asphalt flue gas.

- The whole system is in a full closed, no leakage, to achieve environmental effects.

- RAP conveyor belt with high temperature material to ensure long working life.

- Can adjust the amount of air, control the exhaust temperature, improve the regeneration drum thermal efficiency.

- And the main asphalt mixing plant online interaction, to achieve two systems automatically coordinate the work.

- Any parts of the failure, the two systems can achieve downtime and alarm

Technical Parameters of RAP Asphalt Recycling Plant

| Model | ZAP-S80 &RAP60 | ZAP-S120 &RAP80 | ZAP-S160 &RAP80 | ZAP-S160 &RAP120 | ZAP-S200 &RAP120 | ZAP-S240 &RAP120 | ZAP-S240 &RAP160 | ZAP-S320 &RAP160 |

| Raw Material Production capacity under standard conditions(T/h) | 80 | 120 | 160 | 160 | 200 | 240 | 240 | 320 |

| RAP Production capacity under standard conditions | 60T/h | 80T/h | 80T/h | 120T/h | 120T/h | 120T/h | 160T/h | 160T/h |

| Total output of equipment under standard conditions (including RAP) | 120T/h | 175T/h | 240T/h | 280T/h | 280T/h | 320T/h | 360T/h | 400T/h |

| Installed power(KW) | 265+130 | 370+150 | 500+150 | 500+210 | 570+210 | 640+210 | 640+300 | 870+300 |

| Emission concentration | <30mg/Nm³ (Bag house dust filter) | |||||||

| Environmental noise | <80 db (control room) | |||||||

| Mixer capacity(kg/b) | 1500 kg/batch | 2000 kg/batch | 3000 kg/batch | 3500 kg/batch | 3500 kg/batch | 4000 kg/batch | 4500 kg/batch | 5000 kg/batch |

| Measuring Accuracy | Static: Aggregate: 0.5% Powder: 0.3% Asphalt: 0.2% Recycled material: 0.5% Additive: 0.2% | |||||||

| Filtering Area(㎡) | 650 | 770 | 1050 | 1150 | 1150 | 1350 | 1350 | 1600 |

| RAP Add ratio | 60% | 50% | 30% | 40% | 40% | 35% | 50% | 40% |

| Optional items | 1.Bitumen smoke treatment system. 2.The whole station package and dust collecting system. 3.Foam asphalt system (warm mixing system). | |||||||

|