| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | EDI Water Treatment Plant |

|---|---|

| Brand Name: | CHUNKE |

| Model Number: | CK-EDI |

| Certification: | ISO9001,RoHS,SASO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1 unit |

| Price: | Negotiate |

| Payment Terms: | L/C, T/T, Western Union,paypal |

| Supply Ability: | 20 units per month |

| Delivery Time: | 15-30 working days |

| Packaging Details: | Wooden or carton |

| Material: | Stainless steel |

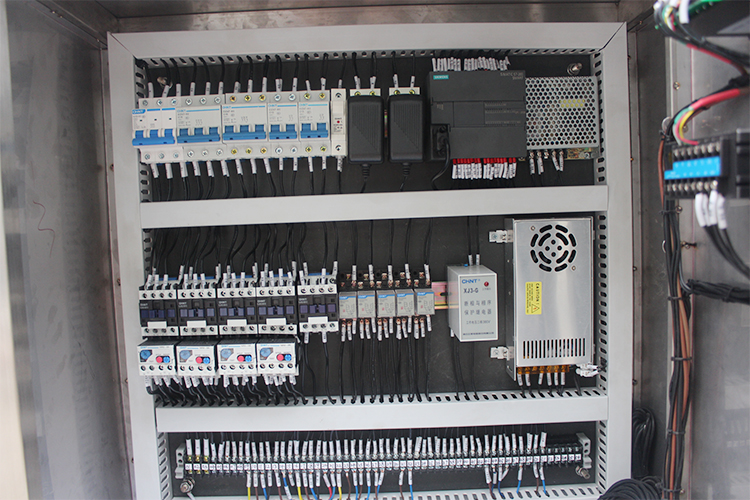

| Automatic Grade: | Full Automatic |

| After-sales Service Provided: | Online support,Field installation, commissioning and training |

| Application: | Purification |

| Control: | automatic/ manual |

| Warranty: | 1 year |

| Flow rate: | 1m³ per hour |

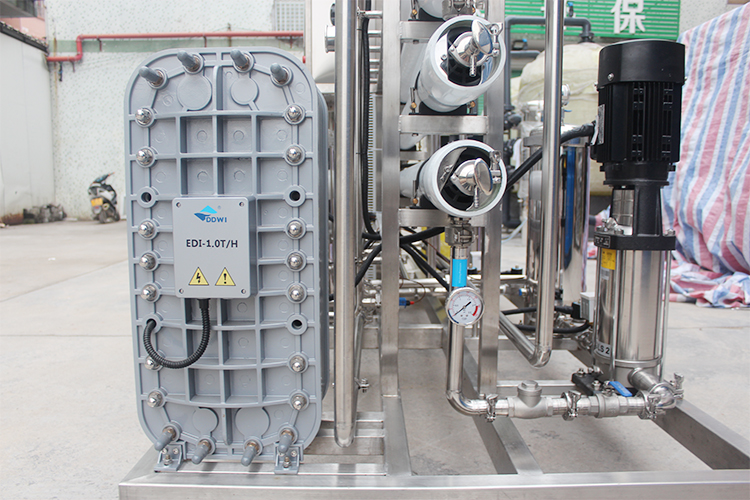

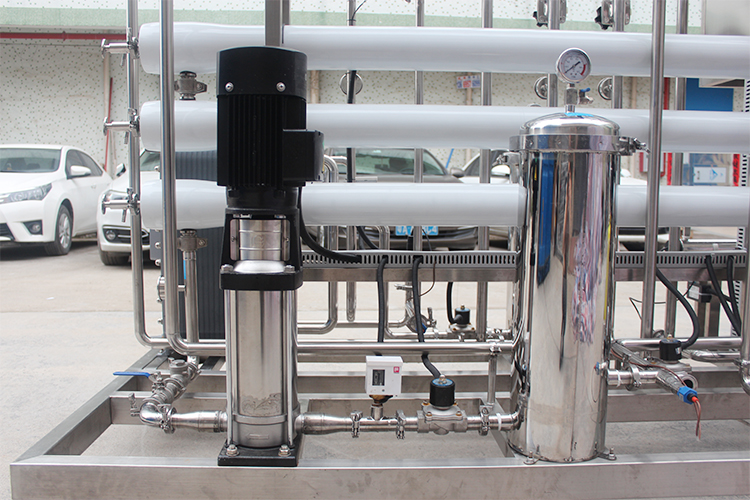

1000lph 2 Stage RO Water Purification System With Edi Module

Treatment Plant

Advantage of the EDI system

1.System can produce water continuously and high degree automation.

2.No need chemical to regenerate, easy operation and maintenance.

3.Core components of ro system are imported USA membranes.

4.Automatic switch on when low water level, and switch off when

high water level

5.System flushes RO membranes automatically, reducing membranes

polluted speed.

6.Water shortage protection for multi-stage pump

7.Product water conductivity meter can monitor water quality online

continuously.

8.Low operation cost and long life span

Detail image of the 2 stage RO+EDI system

Customized Capacity

| Model | Productivity | Motor power | Recovery rate | Outlet water conductivity | Raw water conductivity |

| CK-RO-500L | 0.5 | 1.5 | 50 | ≤10 | ≤300 |

| CK-RO-1000L | 1 | 2.2 | 50 | ≤10 | ≤300 |

| CK-RO-2000L | 2 | 3 | 50-60 | ≤10 | ≤300 |

| CK-RO-3000L | 3 | 4.5 | 55-65 | ≤10 | ≤300 |

| CK-RO-4000L | 4 | 6.5 | 55-65 | ≤10 | ≤300 |

| CK-RO-5000L | 5 | 8 | 60-70 | ≤10 | ≤300 |

| CK-RO-10000L | 10 | 15 | 60-70 | ≤10 | ≤300 |

| CK-RO-20000L | 20 | 22 | 65-75 | ≤10 | ≤300 |

| CK-RO-30000L | 30 | 26 | 70-75 | ≤10 | ≤300 |

| CK-RO-50000L | 50 | 55 | 70-75 | ≤10 | ≤300 |

One stage reverse osmosis system:

After the coarsely filtered water passes through the reverse

osmosis membrane, it is a first-order reverse osmosis. The reverse

osmosis membrane is a semi-permeable membrane, which can prevent

large ions such as Ga2 +, Mg2 +, Fe-2, SO4-2, Cl-1, Na + from

passing through. To ensure the effect of reverse osmosis and

protect the reverse osmosis membrane, the scale inhibitor must be

continuously added to the reverse osmosis container. At the same

time, the water temperature must be above 25 ° C (using a steam

heat exchanger in winter) and a certain water pressure. (Pump)

Under a certain pressure, ion-containing water is squeezed through

the reverse osmosis membrane to form two kinds of water. The water

that passes through the reverse osmosis membrane, that is, the

finished water, enters the next link, and the water that does not

pass through the reverse osmosis membrane is discharged After the

first-stage reverse osmosis treatment, the water enters the next

stage-the second stage reverse osmosis.

Two stage reverse osmosis system:

The principle of the second-stage reverse osmosis is the same as

that of the first-stage reverse osmosis. Its role is to further

remove the salt in the water. After reverse osmosis, the water

quality conductivity can approach 1MΩ.CM. After the first and

second stage reverse osmosis pretreatment, the last remaining water

becomes the feedwater of EDI, and the water (concentrated water)

that has not passed through the reverse osmosis membrane is

discharged in time. The ratio is generally 1: 3, which means that

each ton produced Of qualified water, about 3 tons of concentrated

water (reclaimed water) should be drained.

EDI (Electro deionization) processing:

The secondary reverse osmosis water is stored in the intermediate

water tank, and more than 99% of its ions have been removed.

However, to further improve the water quality and produce ultrapure

water, the trace elements and CO2 dissolved in the water must also

be passed through electricity. Dialysis, or EDI treatment, has the

following principles. EDI, or continuous electrosalt removal, uses

mixed ion exchange resins to adsorb anions and cations in water. At

the same time, these adsorbed ions pass through anion and cation

exchange under the action of DC voltage. The film is removed. In

this process, the ion exchange resin is continuously regenerated

electrically, so it is not necessary to use acid and alkali to

regenerate it. This technology can replace traditional ion exchange

devices and produce ultra-pure water with a resistivity of up to

18MΩ.CM. This process technology is known as a revolution in the

water treatment industry. Compared with traditional ion exchange,

EDI has the following advantages: EDI does not require chemical

regeneration; EDI does not require downtime during regeneration;

provides stable water quality; low energy consumption; easy

operation, low labor intensity, and low operating costs.

|