| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

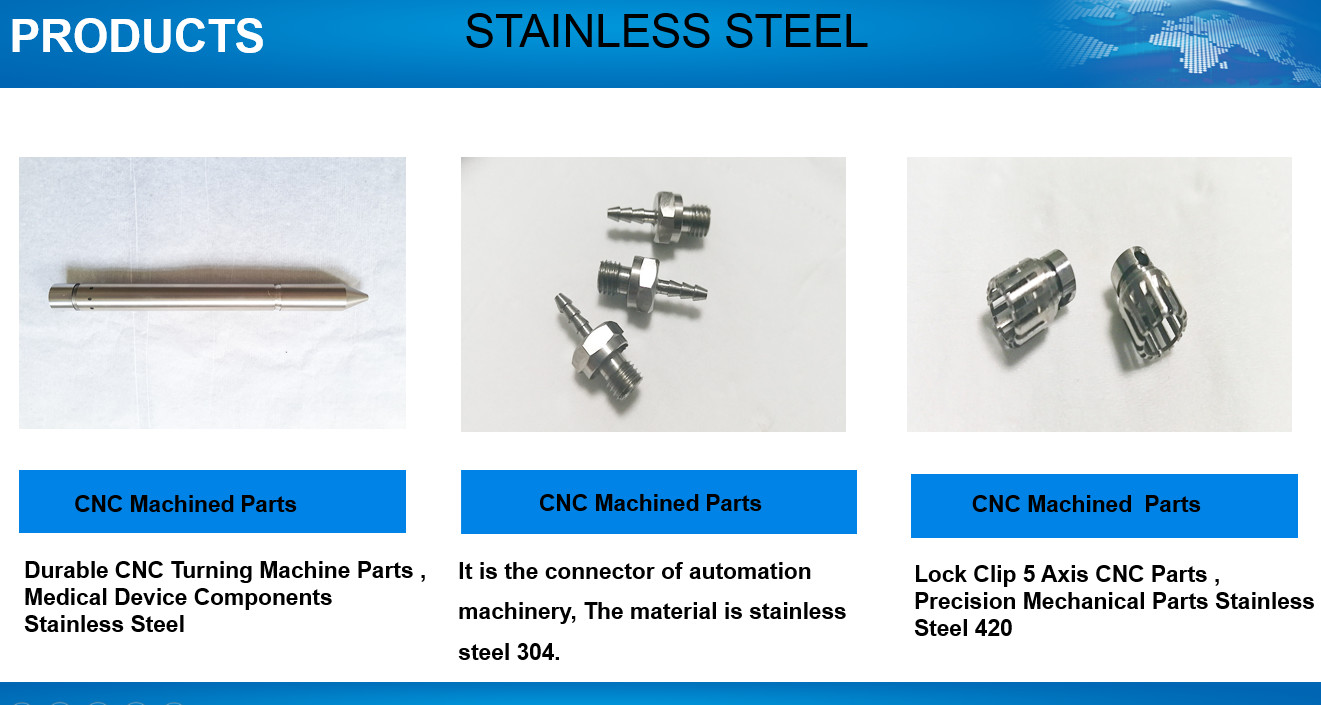

| Categories | CNC Machining Metal Parts |

|---|---|

| MOQ: | 5K |

| Price: | According to your products |

| Payment Terms: | T/T |

| Supply Ability: | 5K/day |

| Delivery Time: | According to customer requirements |

| Packaging Details: | According to customer requirements |

| Place of Origin: | Made in China |

| Brand Name: | OEM/ODM |

| Certification: | ISO |

| Metal: | Galvanized |

| Material: | Aluminum,Stainless steel,Metal,Brass |

| Surface treatment: | anodizing,etc,Ni/Cr/Zinc plating,Heat treatment |

| Application: | Industrial,Medical equipment,Automotive |

| Color: | Any color |

| Finish: | Brushing,Plating,Oil,Blacking etc. |

| Company Info. |

| Samudy Precision Tool Co., Ltd. |

| View Contact Details |

| Product List |

Product Description:

Screw rod support block, which is processed by CNC, is the accessory of transmission rod of mechanical motor.

| Processing Method | CNC Milling, CNC Turning, Turning-Milling Machining, Micro Machining, Grinding, Boring, Tapping. |

| Material | Stainless Steel, Alloy Steel, Carbon Steel, Free-cutting Steel, Brass, Copper, Aluminum, POM, PTFE. |

| Finish Treatment | Polishing, Sand Blasting, Anodizing, Zinc Plating, Nickel Plating, Blackening, QPQ, Painting, etc.. |

| Tech. Standard | ANSI, ASTM, DIN, JIS, BS, GB, ISO, etc.. |

| Application | Medical, Aerospace, Millitary, Instrument, Optics, Food Equipment, AUTO Parts, Furniture, etc.. |

Machining Facilities:

| Equipment Description | Workpiece Dimensions | Processing Accuracy | Quantities | Brand |

| 3-axis machining center | Max. 1000 x 1200mm | +/-0.01mm | 6 | DMG |

| 4-axis machining center | Max. 1000 x 1500mm | +/-0.01mm | 4 | DMG |

| 5-axis machining center | Max. 1000 x 1500mm | +/-0.01mm | 2 | DMG |

| CNC lathe | Max. diameter 100mm | +/-0.01mm | 20 | SMTCL |

| General lathe | Max. diameter 500mm | +/-0.05mm | 2 | SMTCL |

| Turning-Milling machine | Max. diameter 100mm | +/-0.01mm | 6 | DMG |

| Longitudinal lathe | Max. diameter 30mm | +/-0.01mm | 6 | TSUGAMI |

| Automatic lathe | Max. diameter 20mm | +/-0.02mm | 30 | TY |

| CNC Swiss Lathe | Max. diameter 20mm | +/-0.01mm | 6 | TSUGAMI |

Our service:

Samudy Precision Tool Co Ltd bring in 800 T Cold Chamber Die-casting Machine, Hou Er 25 T Punch Machine, CNC1050, CNC850, CNC840, Tokugawa four-axis device, Mirror EDM Machines to ensure superior quality. Our factory is located in the beautiful southern China s Pearl River Delta on the west coast of Shenzhen, with a manufacturing space of 5,000㎡ and a workforce of over 260 employees

Our service includes the plastic mold, magnesium/zinc alloy die casting, aluminum alloy forging parts, as well as mobile phone and digital products, mold design, manufacturing, R & D, production, other secondary processes.

Factory Workshops:

Company Service:

Our service includes the plastic mold, magnesium/zinc alloy die casting, aluminum alloy forging parts, as well as mobile phone and digital products, mold design, manufacturing, R & D, production, other secondary processes.

We have a variety of processing equipment, such as CNC lathe, drilling machine, milling machine, stamping machine, hydraulic press, injection molding machine, welding machine, etc. We have a strong ability to design and production, with a professional engineering team. We have more than five engineers who are good at designing and manufacturing plastic products and metal products and respond to changes at a very fast speed. We can provide solutions for various difficult metal products and plastic products. We process metal products and plastic products at the same time because they complement each other in many cases.

Related Products

|