| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Twin Screw Extruder Machine Parts |

|---|---|

| Brand Name: | Promise |

| Model Number: | Parallel twin screw extruder |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 50mm |

| Price: | USD 500~6500/set |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 889700set per year |

| Delivery Time: | 15 days |

| Packaging Details: | Wooden case |

| Name: | Plastic Granule Machine Anti Corrosion Paralle Screw Element Spare Part Kneading |

| Extruder Type: | 20~135mm |

| Screw material: | Acoording to customer requriement |

| Keyword: | Kneading block Screw Element |

| Application: | Granules |

| Screw design: | Parallel twin screw |

| Plastic processed: | PVC,PP,PE,ABS etc.,PS |

| Condition: | New |

Promise Twin Screw Extruder Machine Parts , Plastic Pellet Making Machine Barrels

Extruder screw

Co-rotating twin screw extruder replacement parts, spare parts. Extruder screw elements, screw components, screw segements.

Screw

Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel.

Material:

1 . W6Mo5Cr4V2

2 . 38CrMoAlA

3 . Cr12MoV

4. Note: Accept customer customization

Using the world's advanced coating technology, to create high wear

and corrosion threaded element products.

High-performance, high wear resistance of the screw element, can

significantly improve product quality and consistency effectively

reduce the machine to replace the screw element frequency, will

minimize production costs.

*convenient interchangeability by agile combination.

*fulfill efficient self-cleaning, transmission, compounding,

pressure-forming, etc.

*made of high tool speed W6Mo5Cr4V2, or anti-corrosion steel

38CrMoAlA by special treatment.

*They are essential and key part of extruders for material to transmission, shearing and plasticization.

Screw Element Technical Data--screw element kneading block for

co-rotating extruder screw | ||||||

ZP-35 | ZP-52 | ZP-65 | ZP-75 | ZP-85 | ZP-95 | |

Do(mm) | 17.2 | 26.2 | 31.8 | 33.8 | 37.8 | 50 |

Di(mm) | 36.6 | 51.4 | 62.4 | 71 | 73.3 | 93 |

Base Material | 1 ) 38CrMoAlA ( JIS SACM645 ) 2 ) Cr12MOV (JIS SKD-11 ) 3 ) 4Cr5MoSiV1 ( JIS SKD-61) 4 ) 42CrMo ( AISI 4140 ) |

Bimetallic Alloy Materials | 1 ) Fe-based alloy 2 ) Ni-based alloy/Deloro alloy 3 ) Co-based alloy 4 ) NiCo-based alloy 5 ) Tungsten carbide/Wolfram carbide |

Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment ( 120 Hours ) : Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv ( HRC56°- 65° ) Hard Chrome Plating treatment : Thickness of Hard Chrome Plating Layer : 0.05-0.10mm Hardness of Hard Chrome Plating Layer : ≥950HV Nickel alloy plating treatment : Bimetallic Barrel/Cylinder : Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer : > 2mm Hardness of Bimetallic Layer: HRC55° - 72° Spraying corrosion wear-resisting dual metal layers |

Basic information | Roughness of the surface : Ra 0.4um Linearity of the screw : ≤0.015mm Linear axis limit : ≤ 0.02mm Hardness after Hardening & Tempering : HB240 - 280 Fragility of Nitration : ≤ Two class |

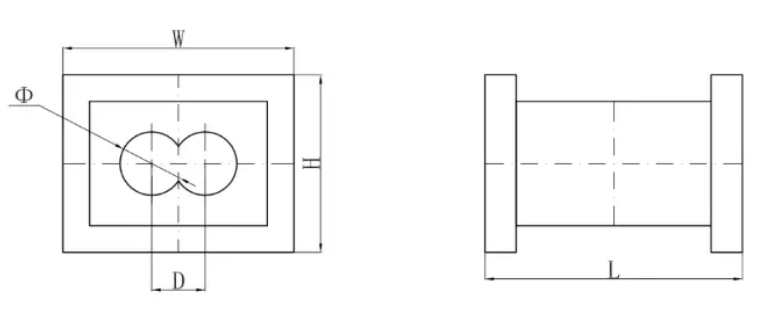

| NO. | Model | Size ( mm ) W * H * L | Hole Diameter ( mm ) | Center Distance ( mm ) |

| 1 | 20 Extruder | 115 * 105* 132 | 23 | 18.4 |

| 2 | 30 Extruder | 135 * 115 * 120 | 30.6 | 26 |

| 3 | 35 Extruder | 140 *0 120 * 140 | 36 | 30 |

| 4 | 36 Extruder | 160 * 140 * 150 | 36 | 30 |

| 5 | 40 Extruder | 175 * 145 * 160 | 41.6 | 34.5 |

| 6 | 50 Extruder | 190 * 150 * 190 | 51 | 42 |

| 7 | 52 Extruder | 200 * 160 * 220 | 52 | 43 |

| 8 | 53 Extruder | 210 * 160 * 220 | 53.3 | 48 |

| 9 | 58 Extruder | 220 * 175 * 240 | 58 | 48 |

| 10 | 60 Extruder | 201 * 170 * 240 | 60 | 52 |

| 11 | 65 Extruder | 260 * 170 * 240 | 63 | 52 |

| 12 | 75 Extruder | 260 * 200 * 290 | 71.8 | 60 |

| 13 | 85 Extruder | 260 * 200 * 290 | 81.9 | 67.8 |

| 14 | 92 Extruder | 310 * 240 * 360 | 92 | 78 |

| 15 | 95 Extruder | 330 * 240 * 360 | 94 | 78 |

| 16 | 110 Extruder | 390 * 240 * 420 | 109 | 91.5 |

| 17 | 125 Extruder | 390 * 290 * 500 | 125 | 98 |

| 18 | 135 Extruder | 370 * 300 * 410 | 134 | 110 |

|