| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rotary Ball Mill |

|---|---|

| Brand Name: | MITR |

| Model Number: | QMQX-2L |

| Certification: | ISO9001:2008/CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | TT,Western union |

| Supply Ability: | 10set per week |

| Delivery Time: | 7-15 working days |

| Packaging Details: | Export Standard Wooden Package |

| Name: | Rotary ball mill |

| Product Name: | 360 degree whole direction roation ball mill |

| Size: | 95*55*65cm/170kg |

| Noise: | <50db |

| Voltage: | 220V 50HZ 0.75KW |

| Driving style: | Gear drive |

| Application: | geology , mineral , metallurgy , electronic , building material , ceramic , chemical , light industry , medicine,beauty,environment production,tea |

| Jar Capacity: | 50-500ml |

Omni-directional planetary ball mill , 360 Degree Rotary Bench Top Ball Mill

| Brand Name |  MITR MITR |

| Model | 360 degree rotating omnidirectional planetary ball mill- MITR-QMQX-2L |

| Single Jar Grinding and Total Volume | 500ml*4=2L(Vacuum jar selection 250ml) |

| General grinding jar material selection | Metal material selection:304 stainless steel,Tungsten carbide(YG8) |

| Nonmetal material selection:ceramic / corundum / alumina, zirconia, agate | |

| high polymer material selection: Nylon, polyurethane, polytetrafluoroethylene(PTFE) | |

| General grinding ball materials | Stainless steel,ceramic,corundum,alumina,zirconia,agate, tungsten carbide |

| Maximum loading per jar | Raw material and grinding ball less than 2/3 of grinding jar |

| Initial size | Friable material less than 10mm,others less than 3mm |

| Final size | Minimum up to 0.1μm |

| Grinding Method | Dry grinding / wet grinding / high energy alloying grinding / vacuum grinding(need customized) / low temperature grinding(need customized) |

| Planetary speed (variable frequency adjustable) | Max Revolution 0-400r/min,Rotation 0-800r/min Planetary total speed:0-3200r/min |

| 360 degree speed(variable frequency adjustable) | 1-14/min |

| speed ratio(revolution:rotation) | 1:02 |

| Adjusting speed control method | PLC Frequency conversion control system,Touch screen control system |

| Driving style | Gear drive |

| Voltage | 220V |

| Power | 0.75Kw |

| Working method | Two or four cans working at the same time |

| Maximum continue working time | 72h(Timing 0-9999h) |

| Weight | 170kg |

| Dimension | 95*55*65cm |

Catalog:

| Model | Spec | With ball mill jar | Remarks | |

| Spec(ml) | Quantities | |||

| QM-QX0.4L | 0.4L | 50-100ml | 2 or 4 | With 50ml vacuum ball mill jar |

| QM-QX1L | 1L | 50-250ml | 2 or 4 | With 50-100ml vacuum ball mill jar |

| QM-QX2L | 2L | 50-500ml | 2 or 4 | With 50-250ml vacuum ball mill jar |

| QM-QX4L | 4L | 50-1000ml | 2 or 4 | With100-500ml vacuum ball mill jar |

| QM-QX8L | 8L | 500-2000ml | 2 or 4 | With250-1000ml vacuum ball mill jar |

| QM-QX10L | 10L | 500ml-2.5L | 2 or 4 | With 250-2.5L vacuum ball mill jar |

| QM-QX12 | 12L | 1L-3L | 2 or 4 | With 500-3L vacuum ball mill jar |

| QM-QX16 | 16L | 1L-4L | 2 or 4 | With 500-4L vacuum ball mill jar |

| QM-QX20L | 20L | 1L-5L | 2 or 4 | With 1000-5L vacuum ball mill jar |

| QM-QX40L | 40L | 4L-10L | 2 or 4 | With 3L-10L vacuum ball mill jar |

| QM-QX60L | 60L | 6L-15L | 2 or 4 | With 5L-15L vacuum ball mill jar |

| QM-QX80L | 80L | 6L-20L | 2 or 4 | With 5L-20L vacuum ball mill jar |

| QM-QX100L | 100L | 10L-25L | 2 or 4 | With 9L-25L vacuum ball mill jar |

| Model | Voltage | Motor power(KW) | Inverter power KW | Total timing(min) | Alternating Run Time | Rotation speed r/min | Noise ≤db | |

| Revolution speed | Rotation speed | |||||||

| QM-QX0.4L | 220V 50HZ | 0.55 | 0.55 | 1-9999 | 1-9999 | 5-450 | 10-900 | <50db |

| QM-QX1L | 220V 50HZ | 0.75 | 0.55 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX2L | 220V 50HZ | 1.1 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX4L | 220V 50HZ | 1.1 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | <50db |

| QM-QX8L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX10L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX12L | 380V 50HZ | 1.5 | 2.2 | 1-9999 | 1-9999 | 5-320 | 10-640 | <50db |

| QM-QX16L | 380V 50HZ | 2.2 | 2.2 | 1-9999 | 1-9999 | 5-280 | 10-560 | <50db |

| QM-QX20L | 380V 50HZ | 3 | 4 | 1-9999 | 1-9999 | 5-230 | 10-460 | <50db |

| QM-QX40L | 380V 50HZ | 3 | 4 | 1-9999 | 1-9999 | 5-220 | 10-440 | <50db |

| QM-QX60L | 380V 50HZ | 4 | 5.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

| QM-QX80L | 380V 50HZ | 5.5 | 5.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

| QM-QX100L | 380V 50HZ | 7.5 | 7.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | <50db |

Application:

It is widely used in geology,mineral,metallurgy,electronic,building material,ceramic,chemical,light industry,medicine,beauty,environment production,tea and so on. Our company have the laboratory with 1000 sets of application cases and maybe could provide you some suggestion.

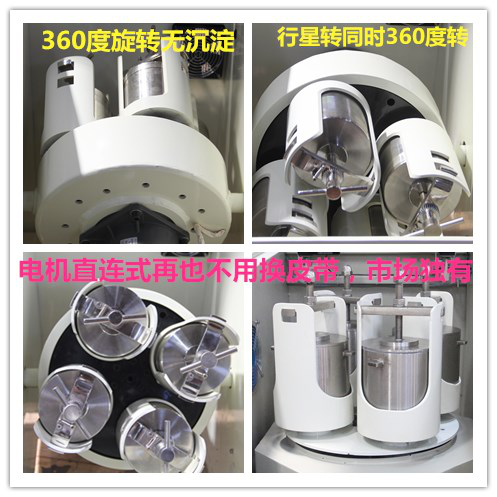

Feature of MITR 360 degree full direction planetary ball mill

1.Window: which could see clearly in the room

2..Pneumatic bar stay: Which bracing the cover on working and convenient and safety operation

3.Damping blanket: Which inlaid on the edge of the cover to prevent the noise and damage when open and close the cover.

4.Operation panel:It is convenient to operate and flexible operation

5.Grinding with four ball mill jars:We adopted the new style pressure bar,the revolution speed is stable and high efficiency and the granularity finer

6.Under high speed working,effectively enhance the air flowing speed of the body and high efficiency loss of heat, ensuring the normal working.

7.Professional design and super function which is 360 degree whole direction revolution. Grinding omnidirectional and more finer

8.Own design of gear and convenient to move.

9.Ensures the consistency and repeat-ability of the experiment.low noise,high efficiency,function comprehensive,small volume.

10.It can solute the problems for the deposition and sticking of some materials and four samples could be obtained with different sizes in one experiment.

11. MITR 360 degree omnidirectional planetary ball mill 2L is the motor direct connection

Techincal parameter:

Mill jars and Mill balls

Our factory can provide 304 stainless steel jar,Tungsten carbide jar(YG8),ceramic jar,corundum/alumina jar, zirconia jar, agate jar.nylon jar, PU jar, PTFE jar.We can also provide the balls material of stainless steel,ceramic,corundum,alumina,zirconia,agate, tungsten carbide.

Grinding Media

Changsha Mitrcn Instrument Equipment Co., Ltd. specializes in designing, manufacturing and selling experimental equipment. Supported by the state key laboratory of Central South University Powder Metallurgy with Hunan University, Shanghai Jiao tong University and other well-known universities to maintain long-term close technical exchanges and product development cooperation.

The high-tech talents in our company are: doctor, master, eight senior engineer,eight senior technician, ten engineer,six technician.The main business is the R&D, production and sale of experimental equipment and related technical consultation services.

|