| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tungsten Carbide Rolls |

|---|---|

| Brand Name: | XYMJ |

| Model Number: | Customized |

| Certification: | ISO9001 : 2018 |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 2000 kilograms per month |

| Delivery Time: | 7-15 |

| Packaging Details: | Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton |

| Item Name: | Steel working carbide roller |

| Main chemical composition: | 100% Virgin Tungsten Carbide |

| Grade: | YG6C/YG8C/YG11C/YG15C |

| Type: | Power Tool Parts |

| Size: | Customized or Standard |

| Application: | High pressure grinding roll |

| Surface: | Polished or blank |

| Tolerance: | ±0.05mm |

High Precision Cemented Carbide Roller Polished Surface Tungsten Carbide Thread Roller

Applications

Tungsten Carbide is not affected by changes in the environment or

external temperature so these durable rollers can be used in either

extreme heat or extreme cold. Tungsten carbide rollers are valued

for their hardness and resistance to corrosion and, since they can

withstand an elevated level of stress, they are the ideal choice

for clients in the aeronautic and aerospace industries, the

automotive industry and the bearings industry. They are often found

in power steering columns or transmission and navigation equipment

and can also be used for vibro finishing.

We manufacture and supply tungsten carbide rollers for many clients

worldwide for years. Competitive price, excellent roller properties

and best service are the guidelines we always insist in doing

business. The tungsten carbide rollers we can manufacture are with

various specification and tungsten carbide grades. Besides, we can

also manufacture tungsten carbide rollers according to customers’

special design.

Tungsten carbide roll ring is a kind of tool material which

consists of tungsten carbide and cobalt with high hardness and wear

resistance. To take advantage of high wear resistance, long life

and high efficiency of cemented carbide roll rings during the high

speed rolling, attention should be paid as follows when purchasing

and using cemented carbide roll ring.

Grade List

| Grades | Binder (wt %) | WC Grain-Size | Physical Properties | Mechanical Properties | ||||

| Density g/cm3 | Thermal Conductivity W/(M.K) | Average Thermal Expansion Coefficient | HRA | TRS | Compressive Strength | |||

| XY27T | 30 | Extra-Coarse | 12.73 | 60 | 5.8-70-.0 | 79 | 2560 | 2700 |

| XY27 | 30 | Medium-Coarse | 12.65 | 60 | 5.8-7.0 | 79 | 2626 | 2800 |

| XY26 | 27.5 | Medium-Coarse | 12.85 | 65 | 5.6-6.8 | 79.8 | 2653 | 2800 |

| XY28T | 25 | Extra-Coarse | 13 | 70 | 5.5-6.5 | 80.3 | 2750 | 2800 |

| XY28 | 25 | Medium-Coarse | 13.04 | 70 | 5.5-6.5 | 80.8 | 2625 | 3000 |

| XY29 | 22 | Coarse | 13.36 | 70 | 5.5-6.5 | 81.8 | 2840 | 3000 |

| XY30 | 20 | Coarse | 13.48 | 80 | 5.2-6.0 | 82.3 | 2742 | 3200 |

| XY31 | 18 | Coarse | 13.68 | 90 | 5.0-5.8 | 83.3 | 2802 | 3200 |

| XY32 | 16 | Coarse | 13.77 | 90 | 5.0-5.8 | 83.8 | 2872 | 3200 |

| XY32C | 17.5 | Coarse | 13.66 | 90 | 5.0-5.8 | 84.5 | 2872 | 3200 |

| XY33 | 15 | Coarse | 13.98 | 100 | 5.0-5.8 | 84.5 | 2872 | 3200 |

| XY34 | 13 | Coarse | 14.17 | 100 | 4.8-5.6 | 85.5 | 2875 | 3400 |

| XY35 | 10 | Coarse | 14.43 | 100 | 4.8-5.6 | 86.5 | 2753 | 3500 |

| XY36 | 8 | Extra-Coarse | 14.69 | 110 | 4.5-5.4 | 86.8 | 2406 | 4000 |

| XY37 | 6 | Extra-Coarse | 14.87 | 110 | 4.5-5.4 | 87.5 | 2358 | 4100 |

| XY27A | 30 | Medium-Coarse | 12.7 | 60 | 5.8-7.0 | 79.5 | 2780 | 2900 |

| XY28A | 25 | Medium-Coarse | 13.15 | 70 | 5.5-6.5 | 81.2 | 2675 | 3000 |

| XY29A | 22 | Coarse | 13.38 | 70 | 5.5-6.5 | 82.2 | 2750 | 3000 |

| XY30A | 20 | Coarse | 13.5 | 80 | 5.2-6.0 | 84 | 2586 | 3100 |

| XY31A | 18 | Coarse | 13.65 | 90 | 5.5-5.8 | 84 | 2806 | 3100 |

| XY33A | 15 | Coarse | 13.92 | 90 | 5.0-5.8 | 85.5 | 2790 | 3200 |

| XY35A | 10 | Coarse | 14.45 | 100 | 4.8-5.6 | 86.8 | 2456 | 3500 |

| XY36A | 8 | Extra-Coarse | 14.69 | 110 | 4.8-5.6 | 87 | 2460 | 4000 |

| XY37A | 6 | Extra-Coarse | 14.87 | 110 | 4.5-5.5 | 88 | 2386 | 4100 |

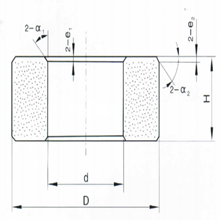

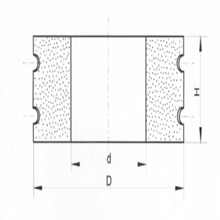

| Dimension | ||

| OD | ID | H |

| 140-500mm | 80-300mm | 10-250mm |

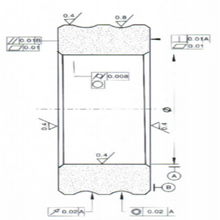

| Grade | I | Ⅱ | Ⅲ | Ⅳ | Special request |

| OD | ±0.02 | ±0.05 | ±0.10 | ±0.15 | |

| ID | ±IT5 | ±IT6 | ±IT7 | ±IT8 | |

| H | ±0.015 | ±0.050 | ±0.100 | ±0.25 |

| Name | Dimension | ||

| D | d | H | |

| Two-groove rolls | 180 | 110 | 55 |

| Two-groovecarved rolls | 180 | 110 | 55 |

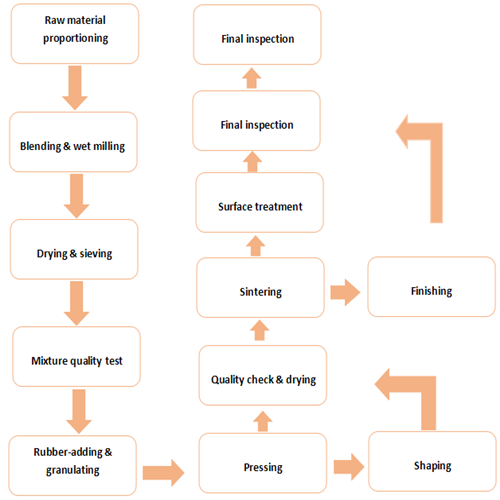

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.

|