| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Refractory Planetary Mixer |

|---|---|

| Brand Name: | PERMIX |

| Model Number: | PMC500 |

| Certification: | CE |

| Place of Origin: | JIAOZHOU CHINA |

| MOQ: | 1 unit |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5-10 units per month |

| Delivery Time: | 15-20 days |

| Packaging Details: | Export Standard Package |

| Product name: | Counter Current Planetary Mixer |

| Input capacity: | 750L |

| Output capacity: | 500L |

| Input weight: | 1200kgs |

| Mixing Power: | 18.5kw |

| Blade QTY: | 1*2 |

Simple Structure PMC750 Counter Current Planetary Mixer No Hidden

Corners

1. Protection Against Wear

The materials and coatings used to manufacture those components

that come into contact with abrasive substances are specially

selected for each individual application.

(1) ceramic materials

(2) wear - resistant alloy plates.

(3) stainless steel materials.

(4) surfacing materials.

(5) polyurethane material.

(6) highchrome alloy.

(7) high wear resistant rubber and cast stone materials.

2.Transmission System

The gearbox unit specially designed for a balanced distributor of

power to the various mixing device and realize rotation and

revolution, ensuring a low noise rotation and high efficiency . The

structure is compact, and the deep mixing the internal part of the

gearbox will not adhere to the material and increase the cleaning

space of the blender.

3. APPLICATION INDUSTRIES

1. Refractories: refractory bricks, unshaped refractories,

2. Ceramics,

3. Glass Raw Material,

4. Casting materials: Casting coatings, Sand mixing,

5. Pot Clay,

6. Concrete

Precast concrete: sleepers, track slabs, various block bricks,

metro tunnel segments, PC components, PCCP water pipe,

Lightweight aggregate concrete: Light soil cement slurry,

polyphenylene granule cement slurry, other lightweight aggregate

concrete,

High Performance ready-mixed concrete: Self-leveling mortar, etc.

Others

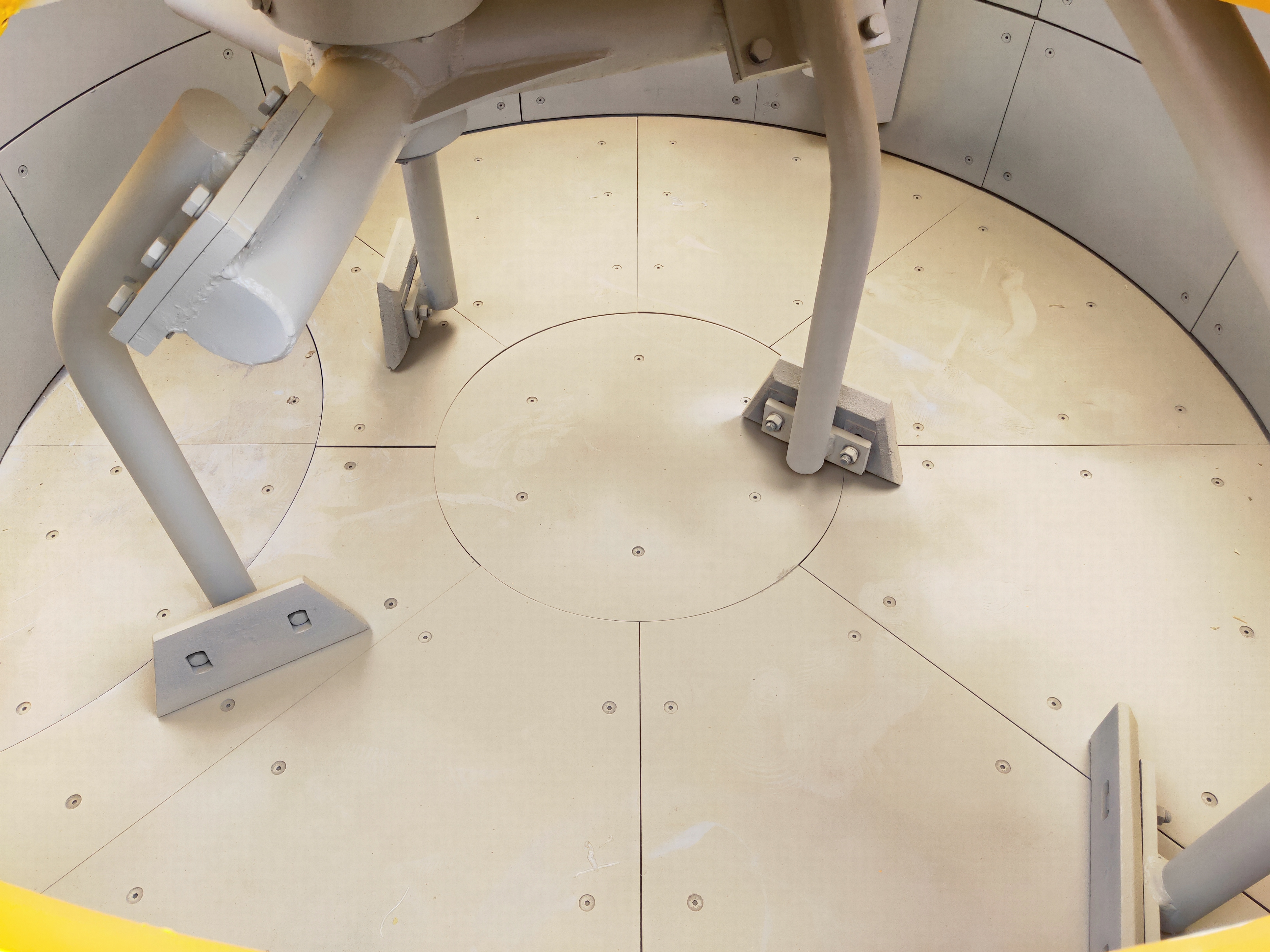

4. Maintaining Door

Large size maintaining door for easy maintenance and cleaning. The

safety control device ensures that the mixer will not start during

maintenance.

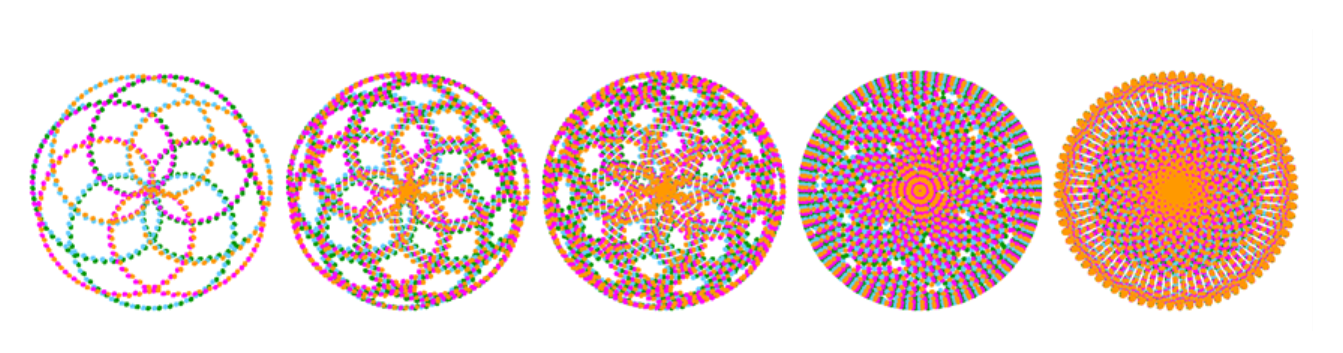

Principle of Motion: Mixing with no hidden corners in the mixing

pan by installing mixing tools and scraper tools on a specially

designed drive system.

The mixing track as follows.

| Technical Specification | ||||||||||||||

| ITEM/(PMC) | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC | PMC 4000 |

| Feeding Capacity (L) | 75 | 150 | 225 | 375 | 500 | 750 | 1125 | 1500 | 1875 | 2250 | 3000 | 3750 | 4500 | 6000 |

| Output Capacity (L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Feeding Weight (kg) | 120 | 240 | 360 | 600 | 800 | 1200 | 1800 | 2400 | 3000 | 3600 | 4800 | 6000 | 7200 | 9600 |

| Mixing Power (kw) | 3 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 132 |

| Discharging Power (kw) | Pneumatic Discharge(Hydraulic Discharge Optional) | 3 | 3 | 3 | 4 | 4 | 4 | 4 | ||||||

| Mixing Star*Blade | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 2*2 | 2*2 | 2*2 | 3*2 | 3*3 | 3*3 | 3*3 |

| Side Scraper | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Discharge Scraper | - | - | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Weight (kg) | 750 | 1000 | 1300 | 1500 | 2000 | 2400 | 3900 | 5500 | 6000 | 6500 | 9200 | 11000 | 12000 | 17500 |

| Lifting Power (kw) | - | - | - | 3 | 4 | 4 | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 30 | - |

| Dimension (L*W*H) mm | 950* | 1664* | 1670* | 1860* | 1870* | 2230* | 2580* | 2891* | 3058* | 3223* | 3625* | 3893* | 3893* | 4594* |

|