| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Bottle Labeling Machine |

|---|---|

| Brand Name: | Sunswell |

| Model Number: | TB |

| Certification: | CE, SGS |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets/month |

| Delivery Time: | 60 days after receiving down payment |

| Packaging Details: | Wooden case |

| Product name: | Hot Melt Glue Labeller |

| Voltage: | 220V/380V/Customized |

| Automatic grade: | Full Automatic |

| Condition: | New |

| Driven type: | Electric |

| Type: | Labeling Machine |

| Packaging type: | Plastic |

| Application: | Food,Beverage |

| After-sales service provided: | Online support,Engineers available to service machinery overseas |

| Packaging material: | Wooden Case |

| Warranty: | 1 Year |

| Function: | labeling |

| Material: | SUS304 |

| Company Info. |

| Zhangjiagang Sunswell Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

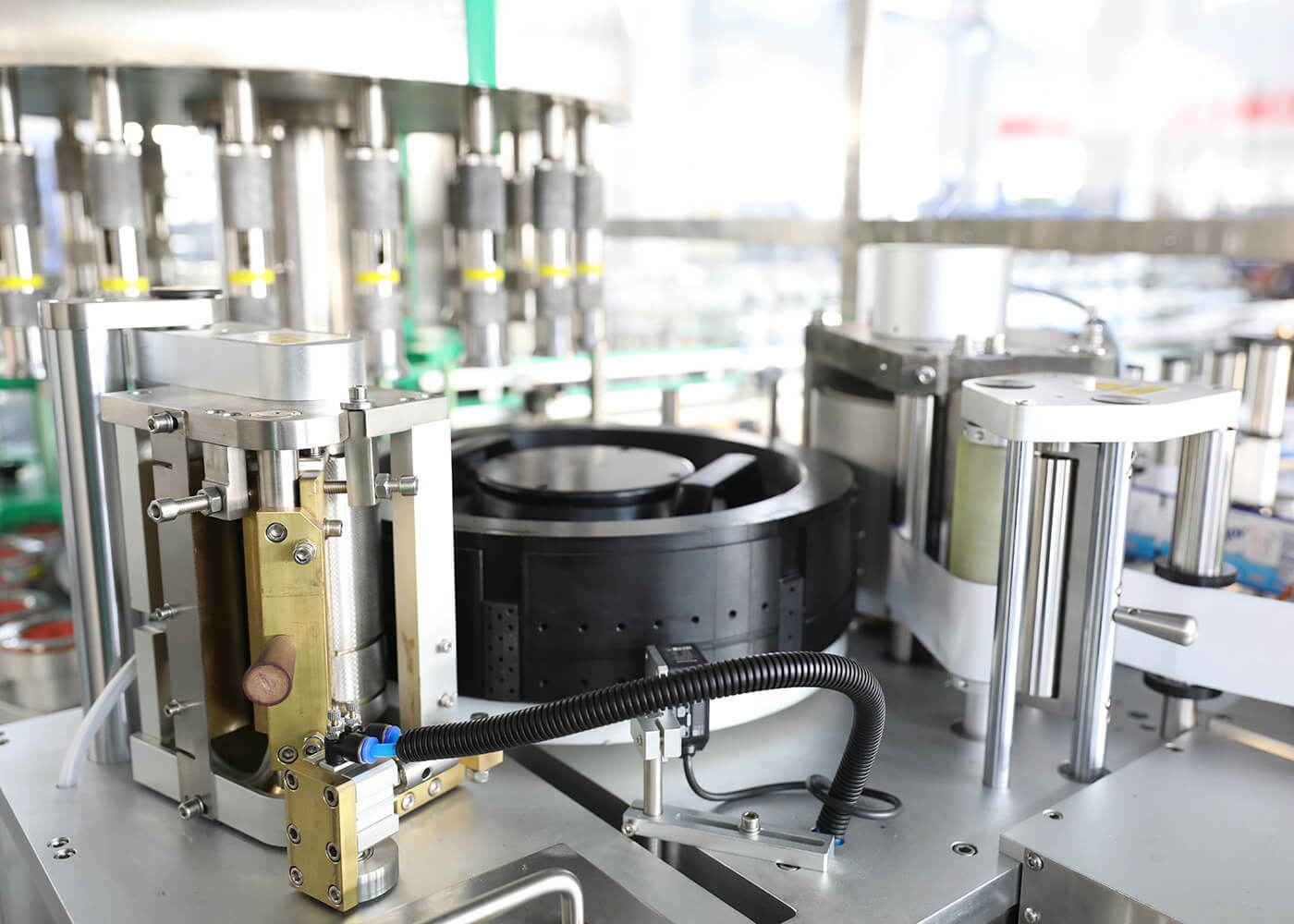

Fully Automatic Rotary Round Bottle Square Bottle Roll-Feed OPP/BOPP Film Hot Melt Glue Labeling Machine

Composition

- Main rotary wheel

- Touch-screen

- Electronic-controlled cabinet

- Label station support regulation device

- Rack- Infeed screw

- Infeed starwheel

- Label reels

- Label station

- Discharge starwheel

- Comfort label institution

- Glue supply system

1. Equipment constitutes

A: Mainframe

- SANYO servo system

- SANYO servo drive system

- SANYO motion controller

- Siemens PLC

- Siemens Color Touch-screen HMI

- Japan SUNX Digital Color Mark Sensor

- Japan SUNX Detection Sensor for coating adhesive

- Japan SUNX Photoelectric Sensor

- Japan SUNX Pressure Sensor

B: Mechanical parks

- Transportation institution: TRANSTECNO AC motor 750W (with

deceleration by TRANSTECNO), inverter speed control

- Conveyor: Industrial nylon chain plate conveyor

- Mainframe transportation institution: TRANSTECNO AC motor 1.5Kw

(with deceleration by TRANSTECNO)

- Sub bottle institution: Industrial worm sub bottle institution

- Into bottle institution: With worm sub bottle institution and

starwheel position feeding institution to ensure the accuracy and

stability of loading

- Position institution: Mechanical pre-location, using the camwheel

institution to planish the bottle for label positioning

- Labeling institution: Containers are picked up by rotary wheel,

labeling during the rotation.

- Supply label institution: SUNSWELL high speed servo OPP label

supply system (drive by servo-motor)

- Pressing label institution: Arc brush unit

- Guided bottle institution: Adjust by double coordinate section

guide rail

- Glue supply system: SUNSWELL hotmelt glue supply system (German

Siemens control system) ensures the accuracy and uniformity of

gluing

2. Safety part of the machine

- Safety protection: In order to keep the operator safety, when the

machine is running please close the protective doors

- Lack of label alarm: Set an alarm to remind the operator to

change the label when the label will be use out

- Lack of bottle alarm: When lack of the bottle the machine will

stop and make an alarm. The machine will restart automatically as

soon as the bottles have been put that will facilitate on-line

production

- Leak of labeling alarm: To control the quality of labeling

- Pressure testing: When the pressure cannot meet the equipment

requirement, the machine will stop to against bad products produce

- Vacuum testing: When the vacuum cannot meet the equipment

requirement, the machine will stop to against bad products produce

- Temperature testing: When the temperature cannot meet the

equipment requirement, the machine will stop to against bad

products produce

Technical parameters:

| Power supply | Three-phase 380V 50 Hz 8000W |

| The total length of equipment | 3000mm(conveyor length 3000mm or can be regulate base on your product lines) |

| Equipment width | 2000mm |

| Conveyor speed | 35m/min (the speed of the transmission lines can be adjusted according to actual production) |

| The method of speed adjustment | uninterrupted - adjust rate |

| The largest Speed of labels feed | maximum speed of 100 meters labels / min |

| The largest speed of labeling | 10000 pcs/H |

| Labeling accuracy | ± 1mm |

| Integrated Labeling accuracy | ± 1mm |

| Product Size: base on client supply container | 2L Φ 100mm |

| Maximum label width | 160mm |

| The maximum length of label | 500mm |

| The maximum diameter of label | 500mm |

| Paper core diameter | 152 mm |

| Labeling glue | leading and trailing edge gluing with hot melt |

| Gluing temperature | 120~160C |

| Type of label | opp label, paper-plastic composite film label, paper label |

| Labeling workstation | 12 per cycle |

| The quantity of labeling mold | 1 set |

| Machine weight | 2000 Kg |

|