| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Sheet |

|---|---|

| Brand Name: | TISCO,LISCO,ZPSS,JISCO |

| Model Number: | 316L |

| Certification: | SGS,TUV |

| Place of Origin: | CHINA |

| MOQ: | 2 tons |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 800tons per month |

| Delivery Time: | 3-5 working days |

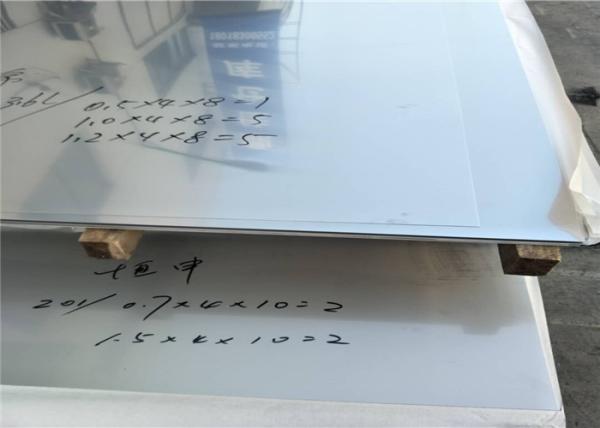

| Packaging Details: | cold rolled waterproof paper and steel strip reinforcement,one package about 2 tons,Load in 20' or 40' GP |

| Thickness: | 0.3-6.0mm |

| Finish: | polished |

| Carbon: | low carbon |

| technique: | Cold rolled |

| width: | 1200 1000 1219mm as your request |

| Length: | 2400 2440 2000 3000mm as your request |

| Shape: | sheet/plate/coil/pipe/bar |

| Edge: | Slit,Mill |

| Other grade: | 304 304L 201 430 321 309s 310s 2205 904L ect |

Cold Rolled 321 2b Surface Stainless Steel Sheet ASTM A312 321 SS Sheet

Welding

Excellent weldability by all standard fusion and resistance

methods, both with and without filler metals. Heavy welded sections

in Grade 321 require post-weld annealing for maximum corrosion

resistance. This is not required for 321.

321 stainless steel is not generally weldable using oxyacetylene

welding methods.

Machining

321 stainless steel tends to work harden if machined too quickly.

For this reason low speeds and constant feed rates are recommended.

321 stainless steel is also easier to machine compared to 321

stainless steel due its lower carbon content.

Hot and Cold Working

321 stainless steel can be hot worked using most common hot working

techniques. Optimal hot working temperatures should be in the range

1150-1260°C, and certainly should not be less than 930°C. Post work

annealing should be carried out to induce maximum corrosion

resistance.

Most common cold working operations such as shearing, drawing and

stamping can be performed on 321 stainless steel. Post work

annealing should be carried out to remove internal stresses.

Hardening and Work Hardening

321 stainless steel does not harden in response to heat treatments.

It can be hardened by cold working, which can also result in

increased strength.

321 Stainless Steel sheet

CHEMICAL COMPOSITION

| Element | 321 | 321H |

| Chromium | 17.00 min. –19.00 max | 17.00 min.–19.00 max. |

| Nickel | 9.00 min.–12.00 max. | 9.00 min.–12.00 max. |

| Carbon | 0.08 | 0.04 min.– 0.10 max. |

| Manganese | 2 | 2 |

| Phosphorus | 0.045 | 0.045 |

| Sulfur | 0.03 | 0.03 |

| Silicon | 0.75 | 0.75 |

| Titanium | 5 x (C + N) min.–0.70 max. | 4 x (C + N) min.–0.70 max. |

| Nitrogen | 0.1 | 0.1 |

| Iron | Balance | Balance |

Mechanical Properties

| Yield Strength 0.2% Offset | Ultimate Tensile Strength | Elongation in 2 in. | Hardness | ||

| psi(min.) | (Mpa) | psi(min.) | (Mpa) | %(min.) | (max.) |

| 30,000 | 205 | 75,000 | 515 | 40 | 217 Brinell |

|