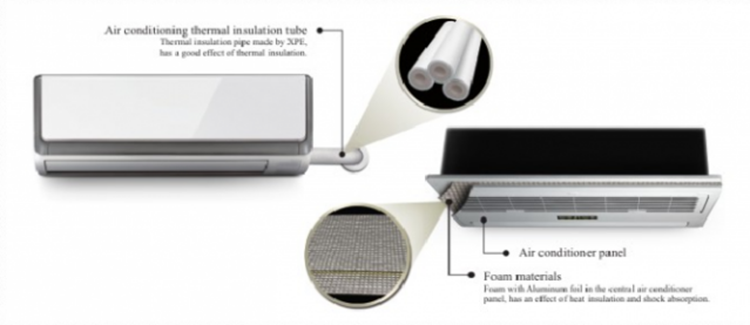

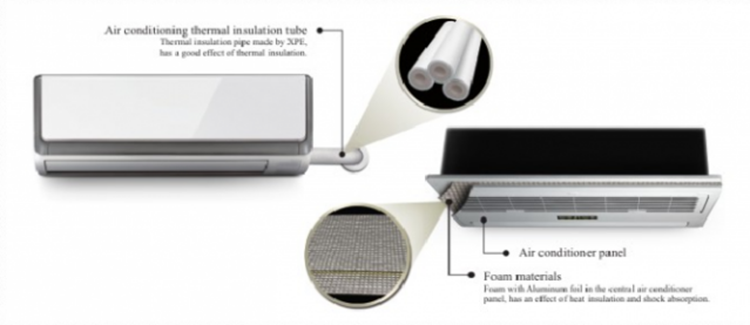

12 mm Recycled Polyethylene Foam Insulation Ixpe Foam For HVAC

Insulation

Advantages:

- High foaming rate

- Low density

- Good elasticity

- Good toughness

- Thermal insulation

- Energy saving

- Noise reduction

- Sound insulation

- Anti-condensation

- Corrosion and aging

- Convenient

| Physical Properties | Test Method |

| Material | Closed Cell Polyethylene | — |

| Color | Charcoal | — |

| Upper Use Limit | 180° F (82° C) constant | — |

| Lower Use Limit | -90° F (-68° C) | — |

| Density | 1.5 lbs/ft³ | ASTM D 1622 |

| Ozone Resistance | Good | ASTM D 1171 |

| Thermal Conductivity (K) | at 75° F (24° C) Mean Temp | ASTM C 177 or C 518 |

| BTU-in/hr-ft² -°F (W/m-K) | 0.230 (0.033) | — |

| Water Absorption | 0.02% by Volume | ASTM E 96 |

| Flame Speed | Less than 25 | ASTM E 84; CAN/ULC-S102.2-M88 |

| Smoke Classification | Less than 50 | ASTM E 84; CAN/ULC-S102.2-M88 |

Features:

- Saves Energy: retain the temperature of the air they are

transporting, reducing energy wastage.

- Prevents Condensation on Ducts: XPE insulation provides a solid

cover around the air ducts.

- Reduces Noise Transmitted Indoors: XPE can carry sound waves all

around the house and carry sounds across rooms such as the noise of

the furnace turning on in phases as well.

- Hot-dipped galvanized steel sheets of lock-forming quality are used

for the manufacturing of standard ducts.

- Ducts are also available in both, stainless steel and Aluminum.

- All straight ducts have beading all along at a distance of 300 mm

between them for reinforce.

Air duct insulation:

XPE / IXPE insulation pe foam is made by closed cell chemical cross-linked

polyethylene foam, adhesive backing and faced with pure aluminum

foil and it's flame retardant as well. Widely used in HVAC duct /

pipe insulation.

CYG PE foam for ducts are manufactured at our state-of-the-art

factory as per customer requirements. All the accessories for

example fittings, attachments, components, and other goods are

manufactured from the finest grade of material and cutting edge

technology. CYG quality controllers check each and in details on

well defined quality parameters. With competitive prices, if you

need to be, the offered range of ducting is also facilitated with

sound proofing and high degree insulation.

CYG PE Foam is a leading supplier of HVAC products located in

Shenzhen, China and serving the trading, contracting, HVAC, MEP,

civil, interior works and building material supply of the country.

Specializing in Thermal insulation, Acoustic insulation, Adhesives,

Sealants, Vapor barriers, Flexible Ducts & Connectors, Fasteners,

copper pipes, tools and all kinds of HVAC products. We provide

solutions and closed cell cross-linked polyethylene foam (XPE or

XLPE or IXPE or IXPP)materials to customers in different countries

including China, USA, UK, UAE, Germany, Southeast Asia etc.

Our track records of quality, safety and reliability have made it a

contractor of choice for major developers, government ministries,

and private clients throughout the world.

CYG polyethylene foam materials are a range of high performance

thermo-reflective insulation products designed for use in steel

framed and concrete residential and commercial roofs, walls,

floors, specifically designed for hot climates. CYG TEFA materials

can reflect up to 97% of radiant heat away from its surface. The

products provide an all-in-one radiant barrier, high performance

insulant and vapor barrier solution.

Specification:

| IXPE foam specification |

| Test Item | Index | Standards |

| 3Times | 5Times | 8Times | 10Times | 15Times | 20Times | 25Times | 30Times | 35Times | 40Times |

| Density (kg/m3) | 300±40 | 200±30 | 125±15 | 100±10 | 66.7±8 | 50±6 | 40±4 | 33.3±3 | 28.6±3 | 26±3 | GB/T6343 |

| Shore Hardnes (°) | Thick>3mm | 65~75 | 60~70 | 50~60 | 45~50 | 35~45 | 30~35 | 25~30 | 18~25 | 13~18 | 13~18 | GB/T2411 |

| Thick≤3mm | | 55~65 | 45~55 | 35~45 | 25~35 | 20~25 | 15~20 | |

| Tensile Stength (Mpa) | T | ≥1.4 | ≥1.3 | ≥0.9 | ≥0.7 | ≥0.5 | ≥0.4 | ≥0.3 | ≥0.2 | ≥0.15 | ≥0.15 | GB/T6344 |

| L | ≥1.6 | ≥1.5 | ≥1.0 | ≥0.8 | ≥0.6 | ≥0.5 | ≥0.4 | ≥0.25 | ≥0.2 | ≥0.2 |

| Elongation (%) | T | ≥210 | ≥200 | ≥150 | ≥130 | ≥130 | ≥130 | ≥110 | ≥110 | ≥100 | ≥100 | GB/T6344 |

| L | ≥230 | ≥220 | ≥170 | ≥150 | ≥150 | ≥150 | ≥120 | ≥120 | ≥110 | ≥110 |

| Tearing Stength (KN/m) | T | ≥10 | ≥9 | ≥8 | ≥6 | ≥4 | ≥2.5 | ≥2 | ≥1.5 | ≥1.3 | ≥1.3 | GB/T10808 |

| L | ≥10 | ≥9 | ≥8 | ≥6 | ≥4 | ≥2.5 | ≥2 | ≥1.2 | ≥1.2 | ≥1.2 |

| Compressed Distortions (%)23℃±2℃,22h | ≤2 | ≤2 | ≤3 | ≤5 | ≤7 | ≤8 | ≤9 | ≤10 | ≤11 | ≤11 | GB/T6669 |

| Size change rate (%)70±2℃,22h | T | ≤-4 | ≤-4 | ≤-4 | ≤-4 | ≤-4 | ≤-6 | ≤-6 | ≤-6 | ≤-6 | ≤-6 | GB/T8811 |

| L | ≤-6 | ≤-6 | ≤-6 | ≤-6 | ≤-6 | ≤-8 | ≤-8 | ≤-8 | ≤-8 | ≤-8 |

| Water Absorbtion (g/cm2)23℃±2℃,24h | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.03 | ≤0.03 | ≤0.04 | ≤0.04 | ≤0.05 | ≤0.05 | ≤0.05 | GB/T1034 |

| Thermal Conductivity (w/m.k) | ≤0.095 | ≤0.095 | ≤0.084 | ≤0.073 | ≤0.065 | ≤0.055 | ≤0.049 | ≤0.045 | ≤0.040 | ≤0.040 | GB/T10297 |