| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sintered Metal Bearings |

|---|---|

| Brand Name: | INWAY |

| Model Number: | SOX |

| Certification: | ISO9001 |

| Place of Origin: | CHINA |

| MOQ: | 1 PCS |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 tons/month |

| Delivery Time: | 5 work days or based on quantity |

| Packaging Details: | Carton+pallet |

| Material: | Steel sintered with layer |

| Lubricating: | Lubricated |

| Application: | Tyer mould |

| Size: | Customized |

| Structure: | Metal to metal |

| Standard: | JIS |

| Company Info. |

| Zhejiang In-way Precision Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

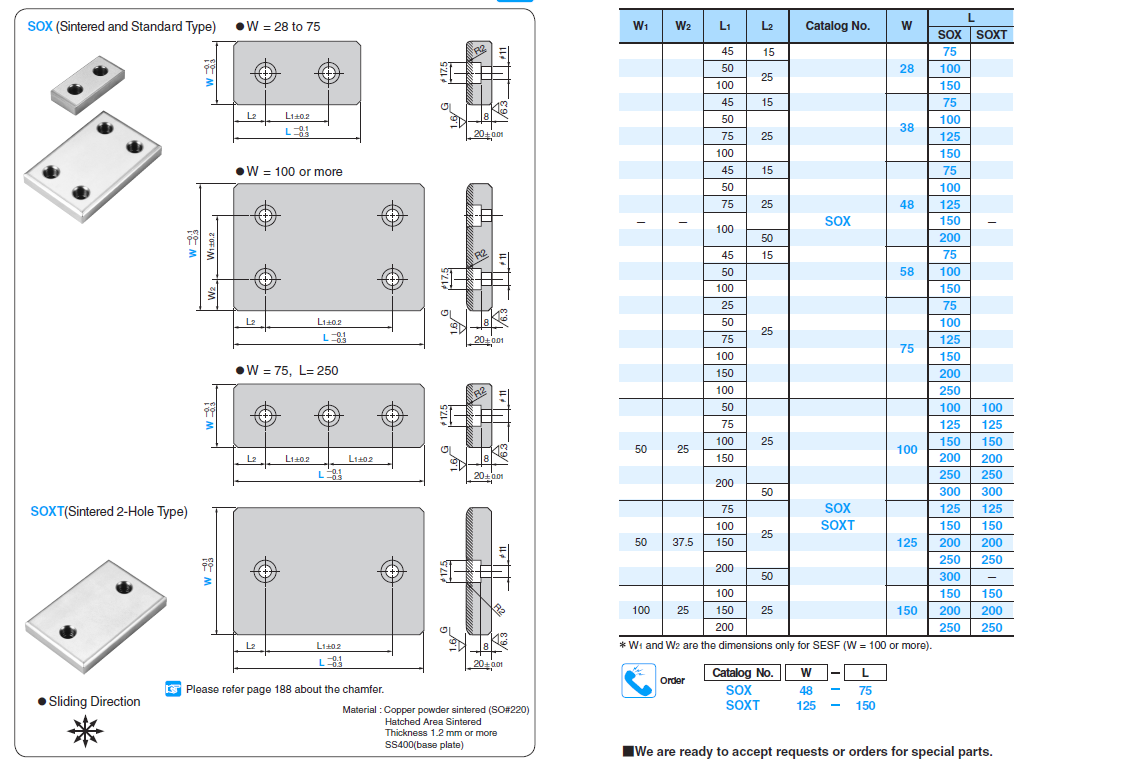

Sankyo SOX SOXT Sintered Metal Bearings With Dispersed Solid Lubricant

Oiles 2000 Sintered multi-layer bearings with dispersed solid lubricant

Bearings with superior wear resistance that may be used in any direction

The Oiles 2000 series are composite multi-layer bearings composed of sliding surfaces made of special sintered material and steel back metals. Solid lubricant mainly made of graphite is dispersed in the sintered layer, which is sintered and impregnated with oil.

| Service range | ||

|---|---|---|

| Lubrication conditions | Dry | Periodic lubrication |

| Service temperature range (℃) | -40~+120 | -40~+120 |

| allowable max. contact pressure : P (N/mm2) | 24.5 | 49 |

| allowable max. velocity : V (m/s) | 0.50 | 1.00 |

| Allowable max. PV value (N/mm2・m/s) | 1.63 | 2.45 |

The process of powder metallurgy has (3) basic steps:

The resulting porosity of the sintered parts makes powder metal products especially useful in lubricating applications and as a result, bearings and wear plates are often fabricated from sintered bronze. Powdered metal offer both strength and flexibility. Additionally, they offer a cost effective production process that includes oil impregnation or permanent lubrication.

|